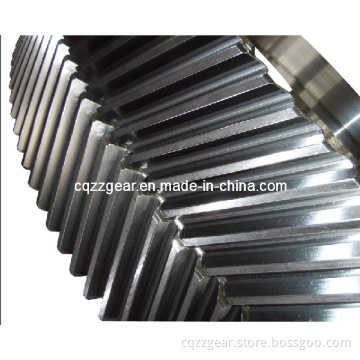

Straight Bevel Gear for Anchor Machine (ZZ1027)

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

1.The main technical characteristics of this product:

1) For ship anchor machine

2) Precision: DIN5

3) Surface Hardness : HRC58-62

4) Processed by our five-axis machining center

5) Material: 17CrNiMo6 or 20CrMnTi ( Or per your requirements)

6) We can process perfectly per your drawing or samples

2. Product range of our company

1) Spiral bevel gear and gear shafts ( Gleason format or Klingelnberg format)

2) Herringbone gear with small or with no undercuts

3) Large straight bevel gear

4) Spur gear

3. Product application

Our products are widely used in the industries such as Thermal power plants, Cement factories, Oil transfer hoist, Metallurgy, Marine propulsion, Coal Mining, Rail transport, Heavy vehicles and water control etc.

4. The main technical results of our company on the processing technology of bevel gears

1) Owns six practical new patents

2) Large processing range: Max diameter 3000mm with unlimited modules

3) "R" shape technology on dedendum to disperse the processing stress,save cost,enlarge contact area to increase torque transmission etc.

4) Carbide stick knife processing instead of traditional knife disc processing in order to increase the processing efficiency and precision level.

5) We are able to achieve the integral processing of large bevel gear shafts by adding an indexing head for the 6-axis machining.

6) Precision: DIN 5 level

7) Sprial bevel gear format: Gleason or Klingelnberg

5. Heatment

Normalizing,Tempering,Carburizing

6. Tests

1) Metallographic test

2) Untrasonic test

3) Magnetic particle test

4) Three-coordinate test

5) Gear rolling test

6) Gear precision test

7. Main euipments for processing the bevel gear tooth profile

Our company has a complete set of specialized equipments for spiral bevel gear manufacturing and other auxiliary processing equipment. Such as grinding, drilling and milling equipments. The bevel gear tooth profile processing equipment is mainly the American Gleason milling machine, the Gleason grinding machine, and the 3 set of 5-axis machining centers (DMU340P,DMU210P, DMU160P) manufactured by DMG in Germany.

![Straight Bevel Gear for Anchor Machine (ZZ1027)]()

With years of experiences and our advanced equipments & professional engineering team,believe we can support you a lot in this area.

In case of any further questions,please feel free to let us know.

Thanks.

1) For ship anchor machine

2) Precision: DIN5

3) Surface Hardness : HRC58-62

4) Processed by our five-axis machining center

5) Material: 17CrNiMo6 or 20CrMnTi ( Or per your requirements)

6) We can process perfectly per your drawing or samples

2. Product range of our company

1) Spiral bevel gear and gear shafts ( Gleason format or Klingelnberg format)

2) Herringbone gear with small or with no undercuts

3) Large straight bevel gear

4) Spur gear

3. Product application

Our products are widely used in the industries such as Thermal power plants, Cement factories, Oil transfer hoist, Metallurgy, Marine propulsion, Coal Mining, Rail transport, Heavy vehicles and water control etc.

4. The main technical results of our company on the processing technology of bevel gears

1) Owns six practical new patents

2) Large processing range: Max diameter 3000mm with unlimited modules

3) "R" shape technology on dedendum to disperse the processing stress,save cost,enlarge contact area to increase torque transmission etc.

4) Carbide stick knife processing instead of traditional knife disc processing in order to increase the processing efficiency and precision level.

5) We are able to achieve the integral processing of large bevel gear shafts by adding an indexing head for the 6-axis machining.

6) Precision: DIN 5 level

7) Sprial bevel gear format: Gleason or Klingelnberg

5. Heatment

Normalizing,Tempering,Carburizing

6. Tests

1) Metallographic test

2) Untrasonic test

3) Magnetic particle test

4) Three-coordinate test

5) Gear rolling test

6) Gear precision test

7. Main euipments for processing the bevel gear tooth profile

Our company has a complete set of specialized equipments for spiral bevel gear manufacturing and other auxiliary processing equipment. Such as grinding, drilling and milling equipments. The bevel gear tooth profile processing equipment is mainly the American Gleason milling machine, the Gleason grinding machine, and the 3 set of 5-axis machining centers (DMU340P,DMU210P, DMU160P) manufactured by DMG in Germany.

With years of experiences and our advanced equipments & professional engineering team,believe we can support you a lot in this area.

In case of any further questions,please feel free to let us know.

Thanks.

Related Keywords

Related Keywords

You May Also Like

You May Also Like