Used Lubricating Oil Purifier-Vacuum Oil Filter/ Oil Recycling

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Chongqing, China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

used lubricating oil purifier-vacuum oil filter/ oil recycling

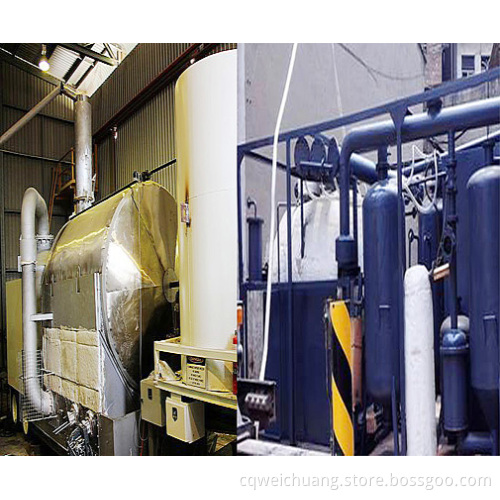

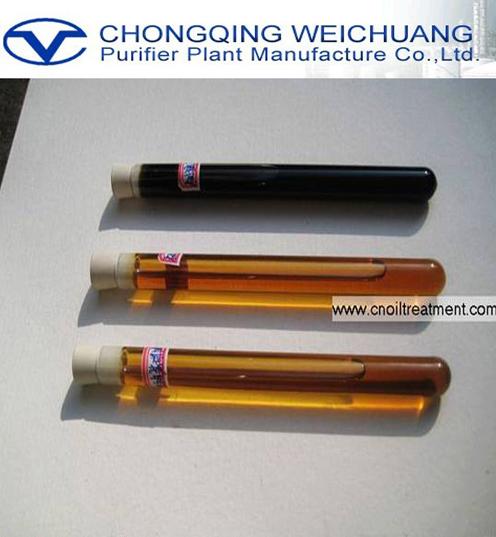

The HCY used lubricating oil purifier-vacuum oil filter/ oil recycling can process the waste lubricating oil the waste engine oil, the waste diesel oil, the used motor oil, the ship oil, and the furnace oil, and the waste tyre oil, and some other kinds of oil., the traditional machine can only process the mineral oil.

Advantages of our products:

1.It is environmentally friendly, because the gas produced during processing will be disposed and into the air with no pollution.

2.And our materials are stainless, so the equipment will have a long life.

3.Our products are cost saving, because it just need 2 workers to operate and the decoloring and deoxiding materials (silicon and carbon) can be reused again and again instead of the materials (water glass, white clay, etc)

4.Also, our regular distillation technology is simpler than the thin film distillation technology, and the speed of processing oil is faster.

5.The advanced fully-automatic temperature controlling system, liquid-level controlling system, pressure protecting system and excellent equipment can ensure operation of the machine with high performance.

6.It can separate from various waste engine oil by controlling the temperature (80-620° C), for example, petrol gas oil, diesel oil, insulating oil.

The working procedure: Waste oil goes through oil pump into primary filtration system to remove big impurities, and then into distillation tank, the liquid waste oil is transformed into oil gas under high temperature in the distillation tank, the oil gas out of the catalysis tower system comes in cooling system for cooling, the oil gas is transformed into liquid oil in the cooling system, the liquid oil comes in the water separation device to separate the oil and water, the oil comes in the discoloration system directly to remove color acid, acid base and sulfur, the oil through fine filter to remove tiny impurities becomes regenerated oil closed to new oil, reused it.

The HCY used lubricating oil purifier-vacuum oil filter/ oil recycling can process the waste lubricating oil the waste engine oil, the waste diesel oil, the used motor oil, the ship oil, and the furnace oil, and the waste tyre oil, and some other kinds of oil., the traditional machine can only process the mineral oil.

Advantages of our products:

1.It is environmentally friendly, because the gas produced during processing will be disposed and into the air with no pollution.

2.And our materials are stainless, so the equipment will have a long life.

3.Our products are cost saving, because it just need 2 workers to operate and the decoloring and deoxiding materials (silicon and carbon) can be reused again and again instead of the materials (water glass, white clay, etc)

4.Also, our regular distillation technology is simpler than the thin film distillation technology, and the speed of processing oil is faster.

5.The advanced fully-automatic temperature controlling system, liquid-level controlling system, pressure protecting system and excellent equipment can ensure operation of the machine with high performance.

6.It can separate from various waste engine oil by controlling the temperature (80-620° C), for example, petrol gas oil, diesel oil, insulating oil.

The working procedure: Waste oil goes through oil pump into primary filtration system to remove big impurities, and then into distillation tank, the liquid waste oil is transformed into oil gas under high temperature in the distillation tank, the oil gas out of the catalysis tower system comes in cooling system for cooling, the oil gas is transformed into liquid oil in the cooling system, the liquid oil comes in the water separation device to separate the oil and water, the oil comes in the discoloration system directly to remove color acid, acid base and sulfur, the oil through fine filter to remove tiny impurities becomes regenerated oil closed to new oil, reused it.

Related Keywords

Related Keywords