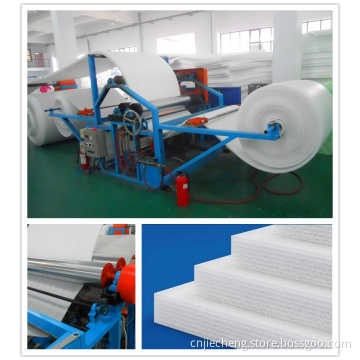

CO2 XPS Foam Board Plastic Machinery

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Chongqing, China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

CO2 XPS Foam Board Plastic Machinery

I. Main Introduction

1. Professional manufacturer of Plastic Foam Machines, sharing 85% domestic market

2. CE, ISO passed

3. Foam agent: CO2 and Freon, adjustable

4. Automatic packing and forming: On line or off line, adjustable

5. Export countries: Mexico, Russia, Iran

6. Main Techincal information:

Raw material: PS

Foam agent: CO2/CO2 and Freon/Freon

Width of board: 600mm

Thickness of board: 20-100mm

Density of board: 29-38kg/m3

Output: 600-850kg/h

Max line speed: 24m/min

II. Product Introduction

XPS foam insulation board has more advantages than traditional insulation material with its perfect honeycomb structure. Its

Excellent thermal insulation, compressive strength, noise, moisture, corrosion-resistant performance, light weight, easy to cut, getting

Widely use in construction, road construction, refrigeration engineering and other fields.

Our company independently developed the CO2 combination of foaming agents instead of the Freon foaming agents; Greatly reducing

The XPS board production costs and increase market competitiveness. Secondly, the CO2 as foaming agent is harmfulness to

Environment, it will annually reduce 250 tons consumption of Freon brings great social environment benefits. Therefore full compliance

With the proposed global "building a low carbon emissions of the industrial system and consumption patterns of development policies",

Promote the global response of climate change has made new progress to make contributions.

I. Main Introduction

1. Professional manufacturer of Plastic Foam Machines, sharing 85% domestic market

2. CE, ISO passed

3. Foam agent: CO2 and Freon, adjustable

4. Automatic packing and forming: On line or off line, adjustable

5. Export countries: Mexico, Russia, Iran

6. Main Techincal information:

Raw material: PS

Foam agent: CO2/CO2 and Freon/Freon

Width of board: 600mm

Thickness of board: 20-100mm

Density of board: 29-38kg/m3

Output: 600-850kg/h

Max line speed: 24m/min

II. Product Introduction

XPS foam insulation board has more advantages than traditional insulation material with its perfect honeycomb structure. Its

Excellent thermal insulation, compressive strength, noise, moisture, corrosion-resistant performance, light weight, easy to cut, getting

Widely use in construction, road construction, refrigeration engineering and other fields.

Our company independently developed the CO2 combination of foaming agents instead of the Freon foaming agents; Greatly reducing

The XPS board production costs and increase market competitiveness. Secondly, the CO2 as foaming agent is harmfulness to

Environment, it will annually reduce 250 tons consumption of Freon brings great social environment benefits. Therefore full compliance

With the proposed global "building a low carbon emissions of the industrial system and consumption patterns of development policies",

Promote the global response of climate change has made new progress to make contributions.

Related Keywords

Related Keywords