High Filtering Accuracy Hydraulic Oil Restoration Machinery

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Chongqing, China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Product Description

High Filtering Accuracy Hydraulic Oil Restoration Machinery, dewatering, cleaning, degassing, NAS 5 Oil Purification

Specifications:

Hydraulic oil restoration machinery

1. Dewatering, cleaning, degassing

2. High filtering accuracy and cleaness

3. No pollution

Introduction:

Generally, hydraulic oil is to be maintained at very high quality of Purification. The Oil often having large sizes of particles is passed through coarse type filter, to trap the large sized particles. Having taken care of micronic and sub-micronic particles, it is further finely cleaned by electro-statically, operated hydraulic oil cleaner & brought to the international standards.

The oil restoration machine is used for purifying the various types of turbine and hydraulic oil used in the machines of the power plant viz Turbine, Generators etc.

This machine conditions Lube oil of grade ISO VG 46 & ISO VG 68 and enhance the parameters of water content from 2000 ppm to 5 ppm and separates (removes) the free water, sludge, gas content and carbon from Lube oil & hydraulic oil.

Features:

1. Double primary-filter structure, large capacity for holding particles, Multi-stage filtration system to ensure high filtration precision. 2. Special polymer materials as filter medium with the functions of broken emulsion, dewatering, removing particles

3. Duplex-Stereo film evaporation technology, equips with unique and advanced dewatering, degassing components, can rapidly and effectively remove water, gas, particles and volatile matter (such as alcohol, gasoline, ammonia, etc. )

4. Automatic backwashing system, improving working efficiency

5. Advanced medium cooling system

6. High quality filtering components, large capacity for holding particles, anti-corrosion, good mechanical performance, long lifetime. 7. Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

8. Adopts interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

Working Principle

When it starts working, the used oil will be poured into the heater to heat under the vacuum pressure, then the heated oil enter into the primary filter which will eliminate the big impurities, then the oil enter into the vacuum separator, the oil will flow the special radiation device, which make the unit/volume oil to produce a large surface area, lets the pollution oil exposure in the low humidity atmosphere, thus the water, air and gas can be eliminated. The treated vapor and gas form the gaseous mixture becomes the liquid through the water tank and the chiller condensation, then the liquid enters water receiver together, the vacuum extracts the surplus gas.

The oil which is drained away water flow into precision strainer where can exhaust particulates (oil purification). According the quantity of the water content, a whole purification needs many times circulation to drain away the water.

After -sales Service

1. Two years guarantee for product quality. ( except man-made damage).

2. Free training, installation and testing are available.

3. Lifelong maintenance Service

4. Spare parts supply

Specifications:

Hydraulic oil restoration machinery

1. Dewatering, cleaning, degassing

2. High filtering accuracy and cleaness

3. No pollution

Introduction:

Generally, hydraulic oil is to be maintained at very high quality of Purification. The Oil often having large sizes of particles is passed through coarse type filter, to trap the large sized particles. Having taken care of micronic and sub-micronic particles, it is further finely cleaned by electro-statically, operated hydraulic oil cleaner & brought to the international standards.

The oil restoration machine is used for purifying the various types of turbine and hydraulic oil used in the machines of the power plant viz Turbine, Generators etc.

This machine conditions Lube oil of grade ISO VG 46 & ISO VG 68 and enhance the parameters of water content from 2000 ppm to 5 ppm and separates (removes) the free water, sludge, gas content and carbon from Lube oil & hydraulic oil.

Features:

1. Double primary-filter structure, large capacity for holding particles, Multi-stage filtration system to ensure high filtration precision. 2. Special polymer materials as filter medium with the functions of broken emulsion, dewatering, removing particles

3. Duplex-Stereo film evaporation technology, equips with unique and advanced dewatering, degassing components, can rapidly and effectively remove water, gas, particles and volatile matter (such as alcohol, gasoline, ammonia, etc. )

4. Automatic backwashing system, improving working efficiency

5. Advanced medium cooling system

6. High quality filtering components, large capacity for holding particles, anti-corrosion, good mechanical performance, long lifetime. 7. Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

8. Adopts interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

Working Principle

When it starts working, the used oil will be poured into the heater to heat under the vacuum pressure, then the heated oil enter into the primary filter which will eliminate the big impurities, then the oil enter into the vacuum separator, the oil will flow the special radiation device, which make the unit/volume oil to produce a large surface area, lets the pollution oil exposure in the low humidity atmosphere, thus the water, air and gas can be eliminated. The treated vapor and gas form the gaseous mixture becomes the liquid through the water tank and the chiller condensation, then the liquid enters water receiver together, the vacuum extracts the surplus gas.

The oil which is drained away water flow into precision strainer where can exhaust particulates (oil purification). According the quantity of the water content, a whole purification needs many times circulation to drain away the water.

After -sales Service

1. Two years guarantee for product quality. ( except man-made damage).

2. Free training, installation and testing are available.

3. Lifelong maintenance Service

4. Spare parts supply

| Item | Unit | TYA-10 | TYA -20 | TYA -30 | TYA -50 | TYA -100 | TYA -150 | TYA-200 | TYA-300 | ||||||

| Flow rate | Lit/hr | 600 | 1200 | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 | ||||||

| Vacuum degree | Mpa | -0.06 ~ - 0.095 | |||||||||||||

| Working pressure | Mpa | ≤0.4 | |||||||||||||

| Temperature degree | °C | 0 ~ 100 (60°C is the best condition) | |||||||||||||

| Demulsification | Min | New oil≤15min, running oil≤30min | |||||||||||||

| cleanliness | NAS | ≤6 grade | |||||||||||||

| Power supply | 380V, 3 PHASE, 60 Hz (or as per required) | ||||||||||||||

| Working noise | DB (A) | ≤75 | ≤75 | ≤75 | ≤78 | ≤78 | ≤78 | ≤80 | ≤82 | ||||||

| Electric heating power | KW | 36 | 40 | 45 | 72 | 80 | 90 | 120 | 135 | ||||||

| Total electric power | KW | 38 | 42 | 47 | 75 | 87 | 101 | 135 | 147 | ||||||

| Inlet (outlet) caliber | mm | 25 | 25 | 25 | 32 | 42 | 50 | 50 | 60 | ||||||

| Size | mm | 1500x1000x 1200 | 1500x1050x 1600 | 1500x1050x1650 |

1600 x 1150 x1700 |

1750x1250x 1850 | 1900x1600x1950 | 1900x1700x2000 | 2100x1700x2100 | ||||||

| Weight | Kg | 450 | 550 | 600 | 750 | 850 | 1000 | 1200 | 1500 | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The dimension and weight will be changed with changing the technical specification

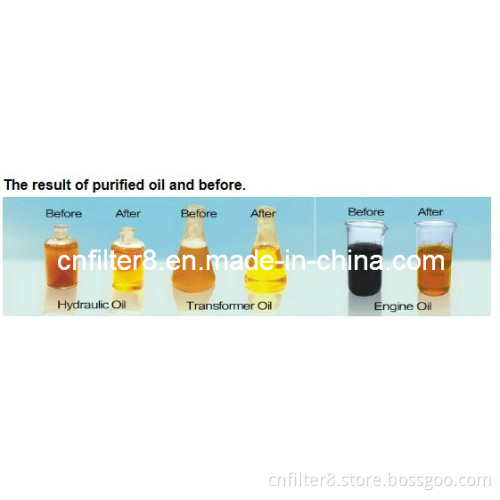

Oil Data after Treatment

|

Moisture (water content) |

≤80 PPM (remove 100% of free water and 95%of dissolved/emulsified water) |

|

Gas Content |

≤0.01% |

|

Suspended Particles (Filtration precision) |

≤1 ~ 5 micron |

|

Demulsification |

New oil≤15min, running oil≤30min |

|

Cleanliness |

≤NAS 1638 Grade 5 |

Related Keywords

Related Keywords