Newest Hydraulic Chamber Board Frame Filter Press (BAM)

- Payment Type:

- L/C, T/T

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Chongqing, China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Frame is made of cast iron/steel, anticorrosion treatment on the surface.

External size of filter plate: 630*630mm,

materials:reinforced polypropylene.

Filter area : 4m2-70m2,

Working pressure ≤0.5Mpa.

Manual shifting plate.

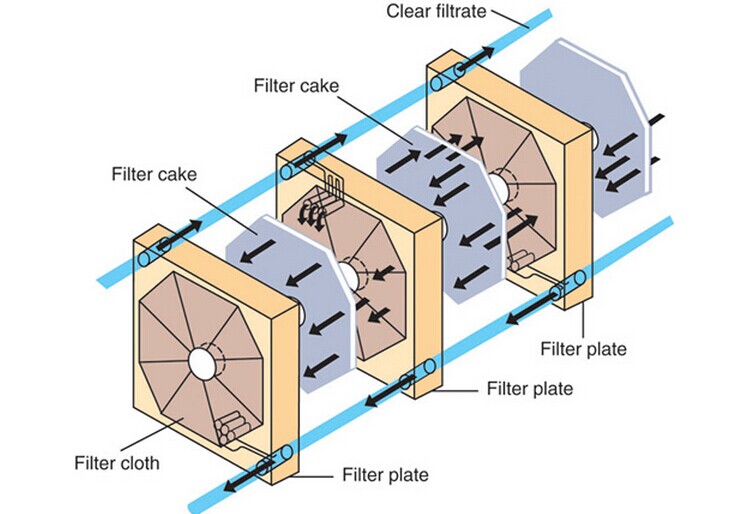

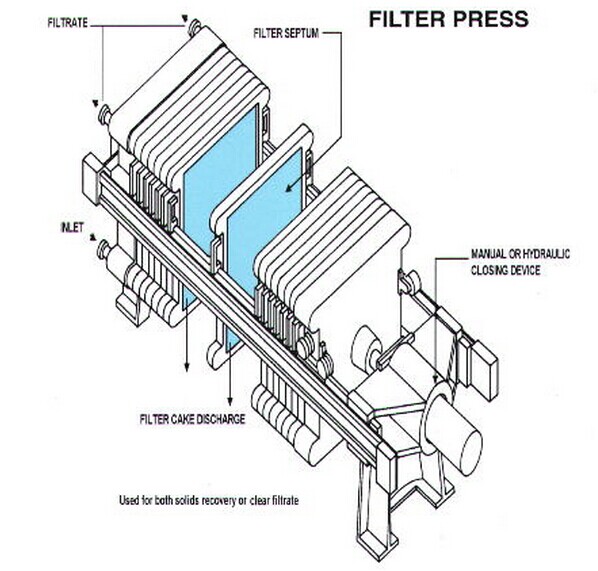

A filter comprises a set of vertical, juxtaposed recessed plates, presses against each other by hydraulic jacks at one end of the set. The pressure applied to the joint face of each filtering plate must withstand the chamber internal pressure developed by the sludge pumping system.

filtration Cycle of MembraneFilter Press :

The filter press is an intermittent dewatering process. Each press operation includes the following steps:

1- Closing of the press: as the filter is completely empty, the moving head activated by the jacks calmps the plates.

2- Filling: For sludge having good filter ability it is best to fill the filter very quickly so as to avoid the formation of a cake in the first chamber before the last ones have been filled.

3- Filtration: When the filtration pump has stopped, the filtrate circuits and central duct, which is still filled with liquid sludge, are purged by compressed air.

4- Filter opening: The moving head is drawn back to disengage the first filtration chamber. The cake falls has a result of his own weight. A mechanised system pulls out the plates one by one.

5- Washing: Washing of clothes should be carried out every 15-30 processing oprations. For mid- or large units this take place on press using water sprayers at very high pressure (80-100 bar).

Product Application of MembraneFilter Press :

coal washing

inorganic salt

mining

alcohol

petroleum

chemical

dyestuff

metallurgy

pharmaceuticals

foodstuff

textile

printing and dyeing

paper making

sewage treatment

Our oil filtration machine:

Series ZY Single-Stage Vacuum Transformer Oil Purifier

Series ZYD Double High Vacuum Transformer Oil Purifier

Series ZYB Multiply-Function insulating oil treatment machine

Series TY Turbine Oil Purification Apparatus

Series TYA Lubricating oil/ hydraulic oil purification unit

Series TYB Portable light Fuel oil purification machine

Series TYD Vacuum dehydrator

Series TYF Phosphate ester fire-resistance oil purifier

Series PL Plate pressure oil purifier

Series TYD Vacuum dehydrator

Series EFD Explosion protection filtration machine

Series BAM Press filtration system

Series ZKCC Vacuum pumping device

Series COP Cooking oil purification machine

Series CYS Centrifugal oil purification machine

Series JL Portable oil filtering and oiling machine

Series EOR series waste engine oil recycling system

Test equipment

1.Transformer oil Breakdown voltage Tester ( BDV test kit) series IIJ-II

2. Acidity tester model ACD-3000I

3. Karl Fischer Water content Tester Model TP-6A / model TP-2100

4. Fully automatic Interfacial Tension Analyzer model IT-800

5.Gas-Chromatography transformer oil gas analyzer model DGA2013-1

6. Kinematic Viscosity tester model VST-8 /model VST-2000

7. Flash point tester (open cup) model TPO-3000

8. Flash point tester (close cup) model TPC-3000

9.TAN-DELTA TESTER,10kV Capacitance and Dissipation Factor Test Set model CDEF

10. CT/PT tester model TPVA-404

11.Transformer turn ratio tester model HYG-II

12. Relaying Protection Tester model TPJB-III

oil purifier, oil filtration, oil purification, oil filter, oil treatment, oil saving, oil recycling, oil processing, oil filtering, energy saving, oil regeneration, oil processor, oil filter, oil process, oil purify, oil regenerating, oil restoration, waste oil disposal, oil reclaimed, oil reclaiming, waste oil management, oil regenerate, oil reconditioned, oil reconstituted, oil restituting

|

Model Specifications |

Filtration area (m2) |

Frame size (mm) |

Flitch thickness (mm) |

Plate number (pcs) |

Frame number (pcs) |

Volume filter room (L) |

Dimensions (L x W x H) (mm) |

Filter Pressure (Mpa) |

Whole Weight (kg) |

Foundation Size | |||

|

BAM-Y20/630-25 BAM-Y25/630-25 BAM-Y30/630-25 |

20 25 30 |

630 X 630 |

25 |

24 30 37 |

25 31 38 |

248 312 377 |

3300*1200*1100 3600*1200*1100 3900*1200*1100 |

0.6 |

4200 4900 3090 |

L | B | A | H |

Related Keywords