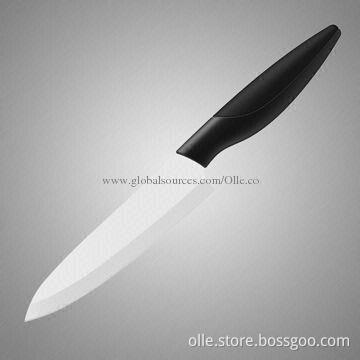

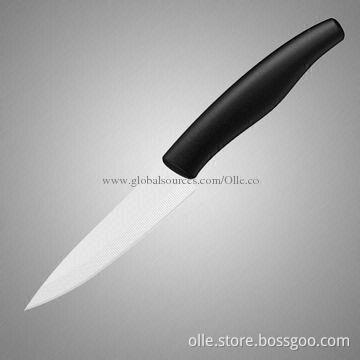

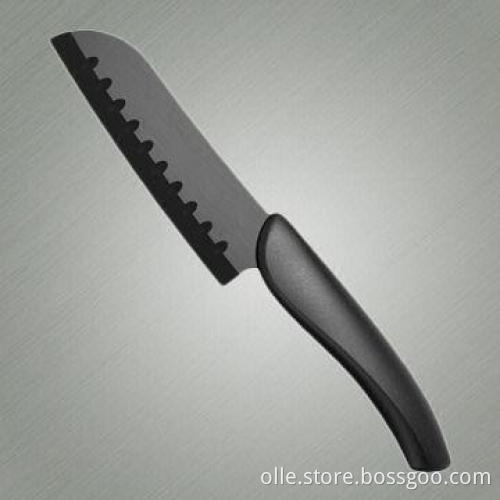

Classical Hollow Edge Knife

- Payment Type:

- T/T ; L/C

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T ; L/C |

|---|

Product Description

Product Description

- Materials:

- Ceramic knife is the only one which uses the 4# zirconia in China

- Particles fineness is 30% higher than the 2# zirconia

- Blade:

- OLLE ceramic knife blades are jade-like appearance, such as soft moist, delicate texture, added a noble enjoyment

- Because of its very high density and clean nature, not easy to breed bacteria flank, cutting fish, fruits, vegetables and crisp, antibiotic pollution

- Easy to clean

- Exclusive processing technique:

- OLLE is the only one in China which has the production technology of cold isostatic pressing, and high temperature sintering by bell kiln, designed and produced by OLLE

- So that our products’ density is higher than 6.02g/cm3, with 30% lower porosity, better strength.

- Handle:

- Instead of using glue and thermal bonding to make handle, chrome plated-end handle ceramic knives use injection molding which is more sanitized

- Healthier and dishwasher-safe

- Sharpness:

- Sharpness and sharpness retention are 30% higher controlled

- Edge angle is between 11-13°, and cutting edge angle is between 35-42°

- Extremely sharp so the nutrition of foods can be locked without sap flow or the hurt to eyes because of volatile substance

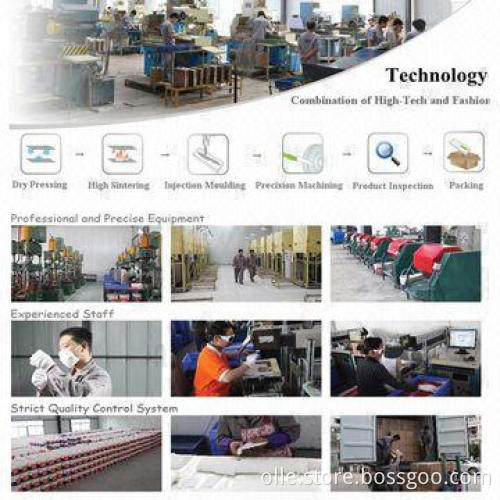

- Dry pressing

- Cold isostatic pressing (exclusive)

- High sintering

- Grinding

- IPQC

- Injection moulding

- Precision machining

- Laser printing

- FQC

- Packaging

- Annual capacity: 20,000,000pcs

- Professional OEM/ODM ceramic knife manufacturer

- Private label service

- Strict quality control within 10 inspections

- Complete industry chain with cost effective

- R&D team member and customer service

- Industry chain: ceramic knife/mold/packaging factory

- Blade colors: white/black/mirror-polished/pattern/more

- Handle colors: any Pantone color/pattern/metallic print

- PP sheath protection and acrylic block holding

- Packaging: presentation box, color box, PET box, customized

- Please contact us for more details

- Ceramic knife is the only one which uses the 4# zirconia in China

- Particles fineness is 30% higher than the 2# zirconia

- OLLE ceramic knife blades are jade-like appearance, such as soft moist, delicate texture, added a noble enjoyment

- Because of its very high density and clean nature, not easy to breed bacteria flank, cutting fish, fruits, vegetables and crisp, antibiotic pollution

- Easy to clean

- OLLE is the only one in China which has the production technology of cold isostatic pressing, and high temperature sintering by bell kiln, designed and produced by OLLE

- So that our products’ density is higher than 6.02g/cm3, with 30% lower porosity, better strength.

- Instead of using glue and thermal bonding to make handle, chrome plated-end handle ceramic knives use injection molding which is more sanitized

- Healthier and dishwasher-safe

- Sharpness and sharpness retention are 30% higher controlled

- Edge angle is between 11-13°, and cutting edge angle is between 35-42°

- Extremely sharp so the nutrition of foods can be locked without sap flow or the hurt to eyes because of volatile substance

Related Keywords

Related Keywords