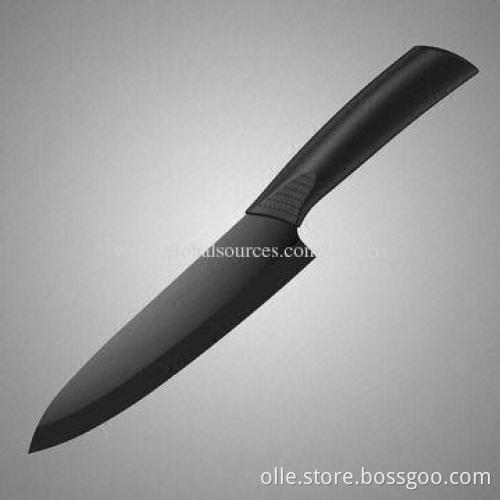

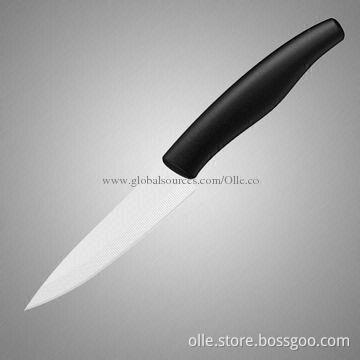

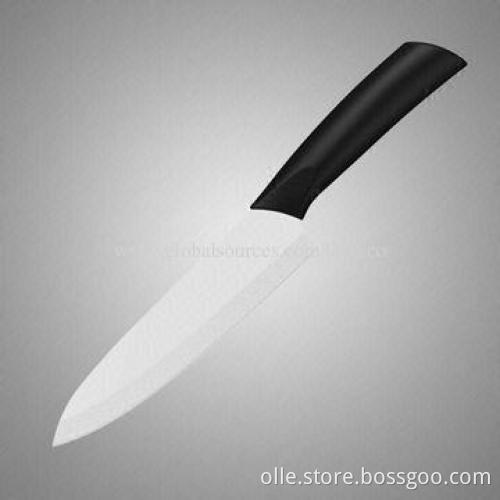

Home 7-inch Ceramic Chef Knife with ABS + TPR Handle

- Payment Type:

- T/T or L/C

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T or L/C |

|---|

Product Description

Product Description

- Materials:

- Blade: zirconium ceramic

- Handle: ABS + TPR

- Material: OLLE ceramic knife is the only one who uses the 4# zirconium in China

- The particles fineness is 30% higher than the 2# zirconium

- The high-tech zirconium materials from refined, high-density, high-hardness, never wear, hardness is second only to diamond.

- Blade: OLLE ceramic knife blades are jade-like appearance, such as soft moist, delicate texture, added a noble enjoyment

- Because of its very high-density and clean nature, not easy-to-breed bacteria flank, cutting fish, fruits, vegetables and crisp, anti-biotic pollution, easy-to-clean

- Exclusive processing technique: OLLE is the only one in China who has the production technology of cold isostatic pressing, and high-temperature sintering by bell kiln, which is designed and produced

- by OLLE

- So that our products’ density is higher than 6.02 g/cm³ with 30% low-porosity, better strength

- Sharpness: OLLE ceramic knives’ sharpness and sharpness retention are 30% higher controlled

- The edge angle is between 11-13°, and the cutting edge angle is between 35-42°

- Handle: instead of using glue and thermal bonding to make handle, we OLLE handle ceramic knives use injection molding which is more sanitary, healthier and dishwasher safe

- OLLE knives are produced via accurate steps: blade molding by pressing, high-temperature sintering, accurate grinding, blade testing, handle injection, sharpness testing, laser engraving, cleaning, packaging

- Blade: zirconium ceramic

- Handle: ABS + TPR

- OLLE has a modernized plant that expands over 30,000 square meters with an annual capacity of 20 million pieces of ceramic knives

- It is the largest and most professional kitchen ceramic knife manufacture in China and the first choice of OEM and ODM factories

- Capacity: OLLE has the strongest production capacity in China-monthly capacity is 20 million ceramic knives

- This enables us to get more than 35% market occupancy in global ceramic knives industry

- Quality control: all our products should endure dozens of technical processes and 10 inspections from raw material to finished products

- So our OLLE knives' quality is stable

- Cost effective: OLLE’s products are cost-effective, for scale effect and strict cost control

- For example, our purchase cost is 15% lower than our rivals

- R&D: OLLE has 25 professional R&D team members

- At present, we have applied 1 invention patent, 10 utility model patents, and 19 design patents

Related Keywords

Related Keywords