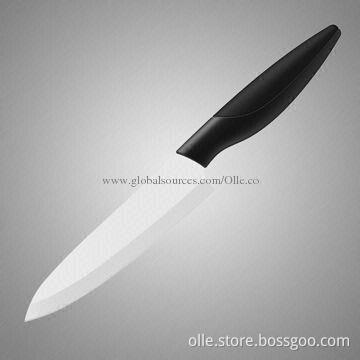

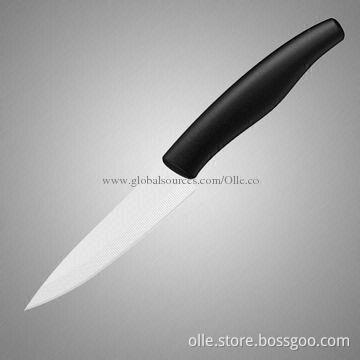

4-inch Faddish Kitchen Knife

- Payment Type:

- T/T or L/C

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T or L/C |

|---|

Product Description

Product Description

- Blade: zirconia ceramic

- Handle: ABS+TPR

- Weight: 37g

- OLLE knives are produced via accurate steps: blade molding by pressing, high temperature sintering, accurate grinding, blade testing, handle injection, sharpness testing, laser engraving, cleaning, packaging

- OLLE has a modernized plant that expands over 30,000 square meters with an annual capacity of 20 million pieces of ceramic knives

- It is the largest and most professional kitchen ceramic knife manufacturer in China and the first choice of OEM and ODM factories

Related Keywords

Related Keywords