Ultrasonic drilling monitor for Construction Pit test bored pile

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Guangzhou, Guangzhou, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Transportation: | Ocean,Land,Air |

|---|---|

| Port: | Guangzhou,Guangzhou,Guangzhou |

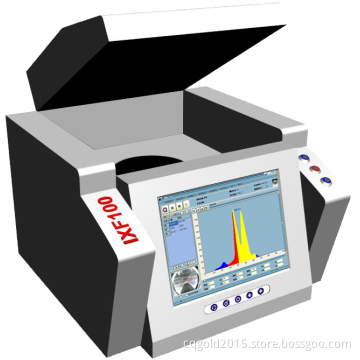

Ultrasonic drilling monitor for Construction Pit test bored pile

The measuring device is a system based on ultrasonic distance measurement and is used to measure the shape and deviations of pile boreholes and slurry trenches. To determine and plot the exact distance to the wall of the borehole in one or two directions, a precision Echolot sensor is inserted along the axis of the borehole. By means of these measurements it is possible to detect and plot local collapse of the borehole wall.

How to use equipment

The purpose of the method is check some parametters of boredhole: size (diameter and depth), shape of the drilled hole (vertical level, tilt,...).

Testing method:

KODEN test utilizes the principle of ultrasonic wave travel from sensor to the wall of boredhole and reflect to the sensor through the bentonite slurry as a media. Wave travelling time varies with size of the hole so it can be interpreted to reflect characteristics of the hole accordingly.

The instrumentation concept is usually prepared in cooperation with the responsible engineers or geologists and is the basis for the technical proposal and tender, which is then supplemented by a detailed description of the methods. This forms the basis for the instrumentation, but also for further work, e.g. the drilling operations. Before and during the instrumentation, checks are constantly carried out and all important working steps are recorded. After completing the instrumentation a more detailed instrumentation report is prepared for the client.

Related Keywords