Series DOD-3 Multi-function engine oil purifier/lube oil purification machine

- Payment Type:

- T/T, L/C, Western Union

- Incoterm:

- CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Chongqing,China |

|---|---|

| Productivity: | 500 set/year |

| Supply Ability: | 500 set/year |

| Payment Type: | T/T,L/C,Western Union |

| Incoterm: | CIF |

| Certificate: | CE, ISO, CCC |

| Transportation: | Ocean |

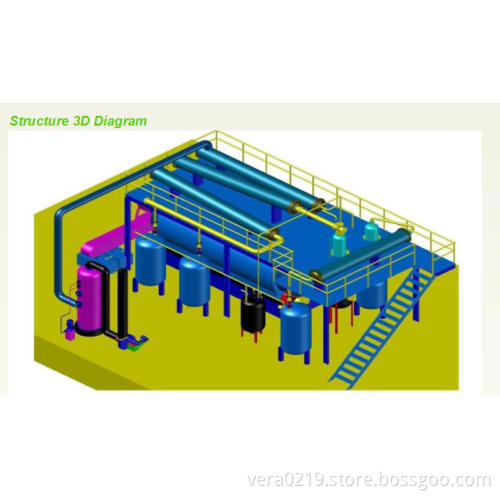

Series DOD-3 Multi-function engine oil purifier/lube oil purification machine

Introduction:

Series DOD Waste Oil Distillation & Converting System can produce

the diesel & gasoline from black dirty engine oil, waste lube oil,

crude oil, waste plastic oil, and waste rubber oil after through

catalytic distillation.

Applications:

Series DOD Diesel Oil Distillation System can produce the diesel &

gasoline from black dirty engine oil, crude oil, heavy fuel oil,bunker

fuel, waste oil sludge, and waste rubber oil after through catalytic

distillation.

Pump the

waste oil into the negative pressure thermal cracking pyrolysis furnace,

heat it and distillate into oil vapour, the oil vapour pass through the

gas manifold, then go throught three-stage condenser to cool down the

hot vapor to petrol and diesel oil; the waste gas will be collected and

transport to the burner as fuel; and the

residue will be discharged automatically by spiral.

Stop

heating when reaction of waste oil is completed, in the distillation

kettle, remove all the remaining residues, then all system can be reused

for next time.

Features:

2) Decompression device is adopted water-circulation type to guarantee the security of the whole system.

3) The unit-time productive capacity as well as the quality of final oil will be rose drastically afterdecompression during the whole production process.

4) The heat system is adopted hot air heating technology,not only safety but also efficiency is increased in theproduction processing.

5)High-efficiency gas heating system. During the oil refining processing, there aretemperature up to 150.Those gases will be burned inthe special gas nozzle to produce a lot of energy and to save the resources.

6) The flue dust removal system with bidirectional spiral hydrodynamic impact on dust chamber can ensure that soot emission can be reached national standard for effluent discharge

7) Exhaust through two safety devices,water seal and gas nozzle,not only eliminate air pollution but also save amount of fuel.Soot emission can be reached the standard of Emission standard of air pollutants for coal-burning oil-burning gas-fired boiler GB13271-2001.

8) waste water: The water distilled from waste oil will be used as cooling water.

Related Keywords