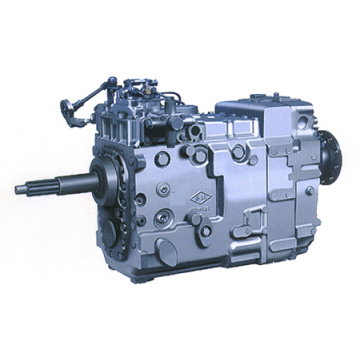

Forging Pinion Mid axle Benz gear

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 500 Piece/Pieces

- Min. Order:

- 500 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Shanghai, Beijing, Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Chongqing China |

|---|---|

| Productivity: | 30000 pcs per month |

| Supply Ability: | 30000 pcs per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

| Port: | Shanghai,Beijing,Chongqing |

Benz Bevel Pinion Mid axle Benz parts

Benz Bevel Pinion Mid axle Benz parts used in Tractor Benze axle. Forging Benz Bevel Gear is belong to axle pinion. Forging Benz Bevel Pinion Axle gear is manufactured by material 20CrMnTi. All the processes are designed and operated in order to improve the quality of the products. Forging Benz Bevel Pinion Axle gear is one the our popular products.

Forging Benz geas Bevel Pinion:

Qijiang Yongyue Gear Co.,Ltd. was established in Oct.2002, and we have more than 15 years experience of gear-manufacturing. Our company covers an area of 80000 M2 with current (first phase) usable area 15000 M2.

There are 212 sets of equipments spaced in our Forging plant, Heattreatment plant, and machining plant.

Leading products: Gearbox Assy:(1)Rear angular transmission;(2)Hybrid transmission of city bus;(3)AMT transmission;(4)Autobalance inter transmission of heavy type.

Other products:A. various gear, shaft, synchronizer and its component of bus and truck (especially be good at component of ZF gearbox), B. various truck`s axle gear, hub gear, ring gear and axle`s component. C. various engine gear, and so on. Totally can produce more than 500 kinds of products.

Main customers and sales status: Qijiang Gear Transmission Co.,Ltd., HanDe Axle, Anhui Ankai, Qingte Group, Guangxi Fangsheng, etc., and gradually enter into overseas retail market, such as Iran, Vietnam, U.S.A., South Africa, and so on.

Our Services

• Professional sales team can provide you quick reply.

• Dozens of engineers can satisfy your OEM requirement according to your drawings or samples.

• Three automatic CNC forging production lines, two automatic heat treatment production lines, advanced mold processing equipment and the complete testing equipment can ensure produce large quantity and high quality products on time.

• 2 years warranty for some products.

Related Keywords