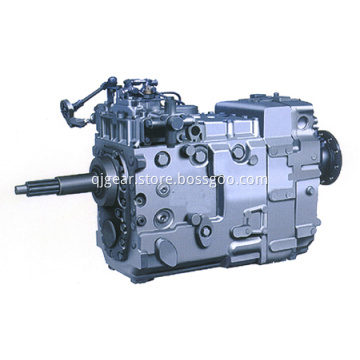

Shaving Steyr driving gear Steyr parts

- Payment Type:

- T/T

- Incoterm:

- FOB, CIP

- Min. Order:

- 500 Piece/Pieces

- Min. Order:

- 500 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Shanghai, Beijing, Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Chongqing China |

|---|---|

| Productivity: | 20000 pcs per month |

| Supply Ability: | 20000 pcs per month |

| Payment Type: | T/T |

| Incoterm: | FOB,CIP |

| Transportation: | Ocean |

| Port: | Shanghai,Beijing,Chongqing |

Forging Steyr driving gear Steyr parts

Forging Steyr driving gear Steyr parts is cylindrical gear assemblied in Axle for Steyr truck. Shaving Axial Gear Axial Parts made by material 20CrMnTi or other material which the customer required. Shaving Steyr Driving Gear applys for Steyr axle with processes of hobbing and shaving and other processes which are controled by QC and SOP and every tolerance is controled in range.

Qijiang Yongyue Gear Co.,Ltd. was established in Oct.2012, its predecessor was Chongqing

Municipality Qijiang Auto Parts Factory(local state-owned). The company is located in Qiaohe Gear City, Qijiang Industrial zone (Area B), Chongqing Municipality----close to the [Fei E Stone" access of YuQian highway, beside the state-level road 210. Company covers an area of 80000M2 with current (first phase) usable area 15000 M2.

Main equipment: more than 300 sets of forging, machining, heat treatment and measuring equipment, includes [Gleason-Fuert" CNC grinding machine SRS410 of U.S.A, CNC universal gear inspection instrument 3040A of Harbin China, worm wheel gear grinding machine of Hungary and Switzerland, inner bore grinding machine of Switzerland, CNC excircle & inner bore grinding machine, CNC chamfering machine, and CNC multi-purpose furnace.

Production Capacity: forgings 8000T/year, heat treatment 6000T/year. Various auto parts and component 2.8 million pcs and sets/year. Annual production value 150 million RMB. We`re good at manufacture gears in shape of dishes and axle with module below 8 and precision around 7. Heat treatment process includes carburizing, tempering, pressure quenching, nitriding, and HF.

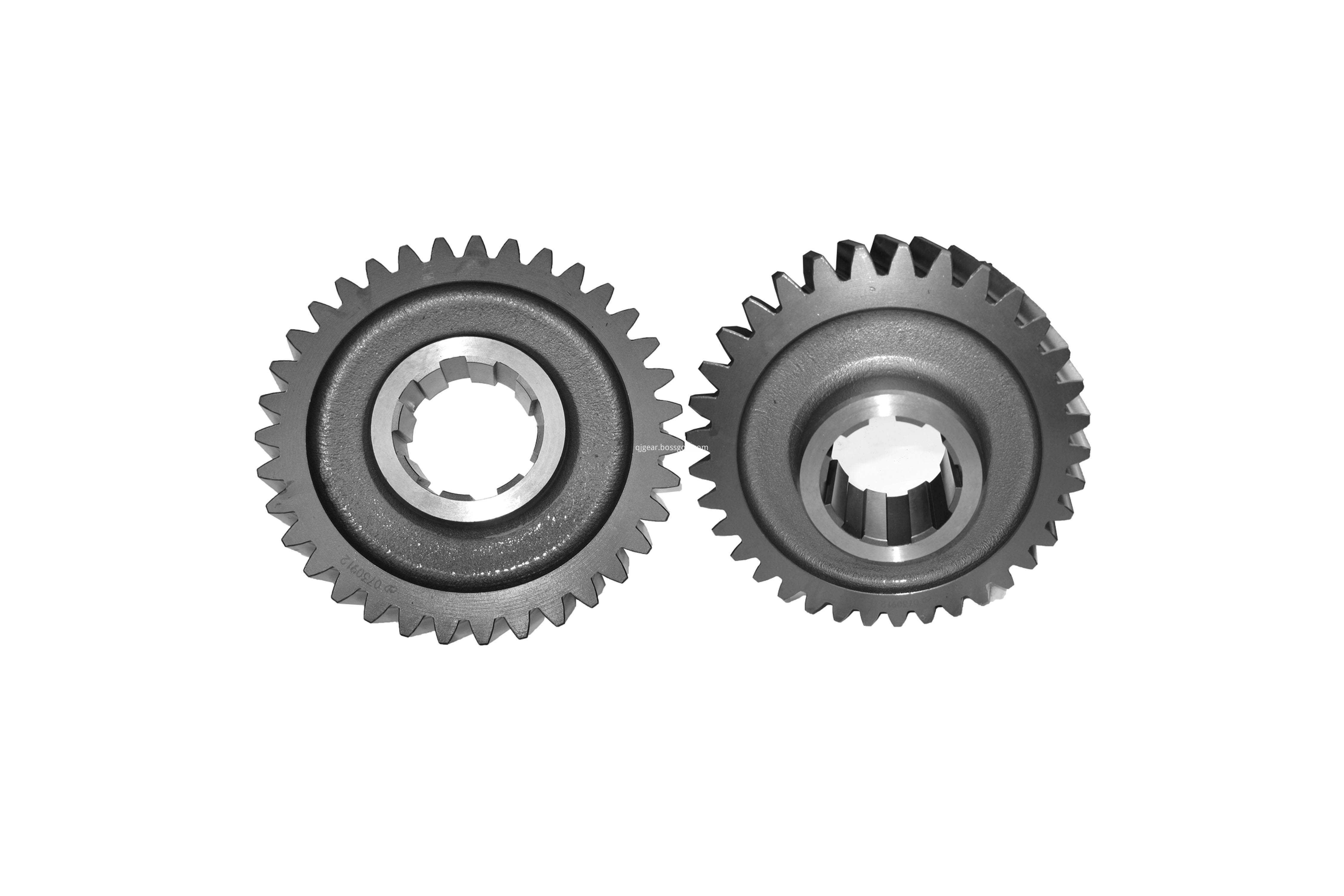

Shaving Axial Gear Axial Parts:

The technical parameter as below table:

| No.of teeth | 35 |

| Module | 5.25 |

| Pressure angle | 20° |

| Helical angle | 15°(LF) |

| Root fillet | 0.3-0.35mm |

| Pitch dia. | ¢190.232 |

| Base dia. | ¢178.014 |

| Modification coefficient | +0.277 |

| Base helix angle | 14°4′34″ |

| Cross-test teeth | 5 |

| Backlash | 0.148-0.348 |

| Center distance | 193 |

| Finish processing | Shaving |

| Part No. | 990 1432 0136 |

Gear precision: DIN3963.3967

Related Keywords