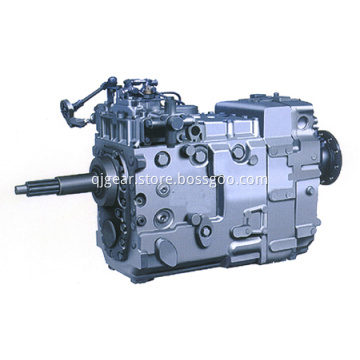

gear 1st ZF gearbox spare parts

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 500 Piece/Pieces

- Min. Order:

- 500 Piece/Pieces

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shanghai, Beijing, Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Chongqing China |

|---|---|

| Productivity: | 30000 pcs per month |

| Supply Ability: | 30000 pcs per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

| Port: | Shanghai,Beijing,Chongqing |

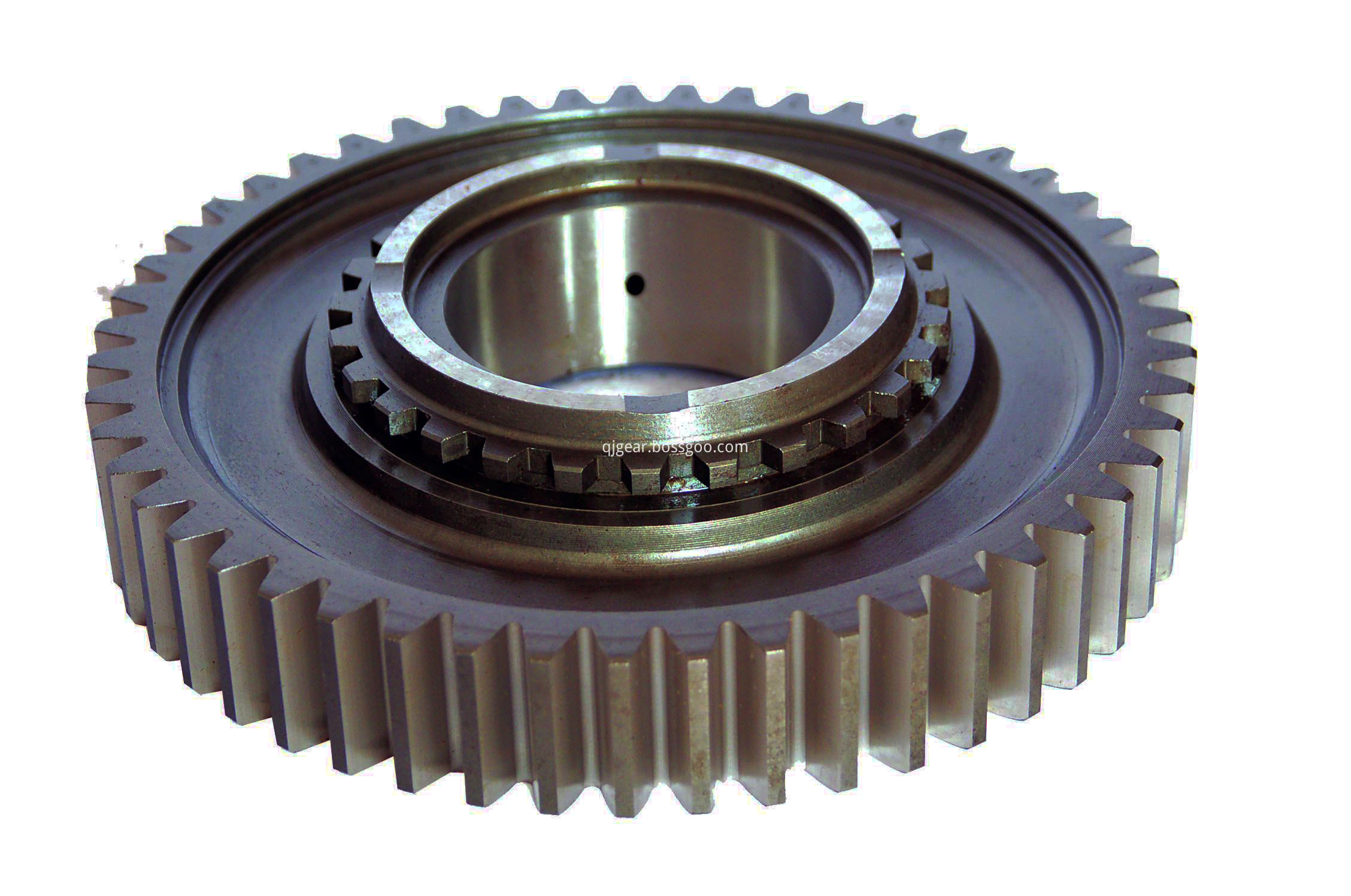

Gear 1st ZF gearbox spare parts

Gear 1st ZF gearbox spare parts is working on main shaft in the ZF gearbox. Gear 1st ZF spare parts contact with gears and transfer power and make transmission in gearbox. Forging Gear 1st Gearbox ZF parts applys for Bus with process of forging, hobbing, shaving, chamfering and heattreatment. Shaving Main Shaft Gear 1st is made by Material 20CrMnTi. In order to get higher precision and reducing noise, the teeth could be processed by grinding.

Qijiang Yongyue Gear Co.,Ltd. was established in Oct.2012, its predecessor was Chongqing

Municipality Qijiang Auto Parts Factory(local state-owned). The company is located in Qiaohe Gear City, Qijiang Industrial zone (Area B), Chongqing Municipality----close to the [Fei E Stone" access of YuQian highway, beside the state-level road 210. Company covers an area of 80000M2 with current (first phase) usable area 15000 M2.

Current registered capital 10 million RMB, total assets more than 100 million RMB

Total staff 268, they`re 15 professionals (external employee included) ------ 4 senior engineers, 8 engineers, 3 technician and senior technician.

Main equipment: more than 300 sets of forging, machining, heat treatment and measuring equipment, includes [Gleason-Fuert" CNC grinding machine SRS410 of U.S.A, CNC universal gear inspection instrument 3040A of Harbin China, worm wheel gear grinding machine of Hungary and Switzerland, inner bore grinding machine of Switzerland, CNC excircle & inner bore grinding machine, CNC chamfering machine, and CNC multi-purpose furnace.

Main Shaft Gear 1st :

Processing with supplied drawings.

Processing according to buyer's samples.Shaving, Grinding, Shapping or Broaching, etc. Technological Processes are optional in order to meet your technological requirements.

Qijiang Yongyue Gear Co.,Ltd. was established in Oct.2002, and we have more than 15 years experience of gear-manufacturing. Our company covers an area of 80000 M2 with current (first phase) usable area 15000 M2.

There are 212 sets of equipments spaced in our Forging plant, Heattreatment plant, and machining plant.

Leading products: Gearbox Assy:(1)Rear angular transmission;(2)Hybrid transmission of city bus;(3)AMT transmission;(4)Autobalance inter transmission of heavy type.

Other products:A. various gear, shaft, synchronizer and its component of bus and truck (especially be good at component of ZF gearbox), B. various truck`s axle gear, hub gear, ring gear and axle`s component. C. various engine gear, and so on. Totally can produce more than 500 kinds of products.

Main customers and sales status: Qijiang Gear Transmission Co.,Ltd., HanDe Axle, Anhui Ankai, Qingte Group, Guangxi Fangsheng, etc., and gradually enter into overseas retail market, such as Iran, Vietnam, U.S.A., South Africa, and so on.

Below is the information in regard to our factory:

Related Keywords