Magnetic Assembly Magnetic Work Magnetic Lifting Devices

- Payment Type:

- L/C, T/T, Paypal

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, China, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001:2018,ROHS,REAC |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,China,Shenzhen |

Magnetic Assembly Magnetic Work Magnetic Lifting Devices

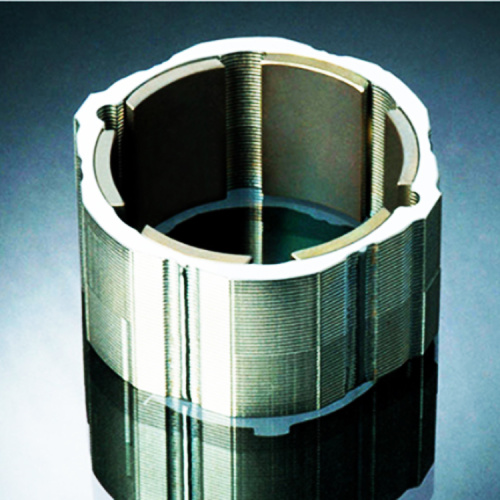

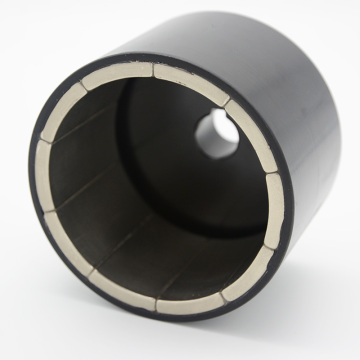

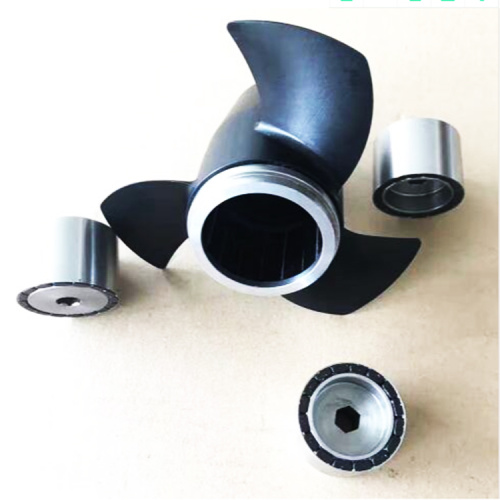

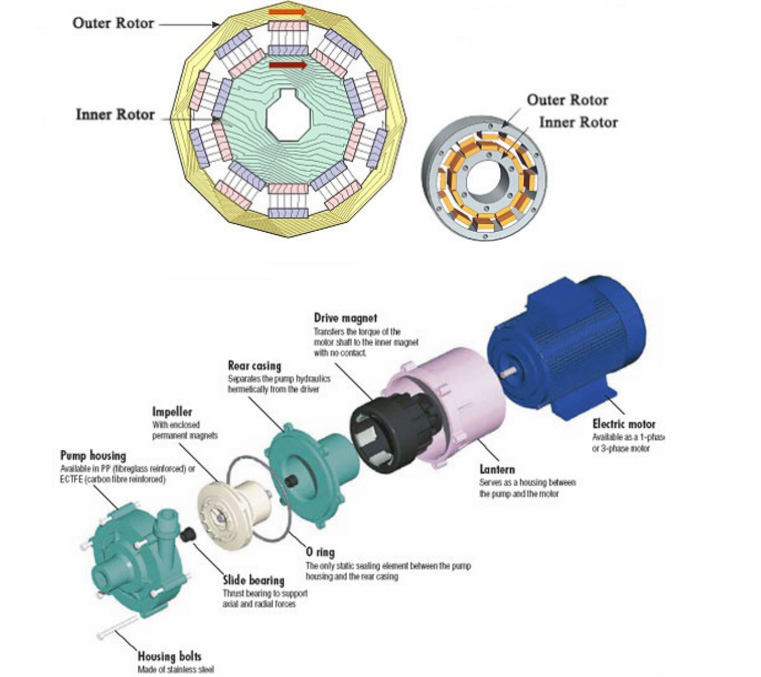

Magnetic coupling is a coupling that transfers torque from one shaft, but using a magnetic field rather than a physical mechanical connection.

Magnetic couplings are most often used for liquid pumps and propeller systems, since a static, physical barrier can be placed between the two shafts to separate the fluid from the motor operating in air. Magnetic couplings preclude the use of shaft seals, which eventually wear out and fail from the sliding of two surfaces against each another. Magnetic couplings are also used for ease of maintenance on systems that typically require precision alignment, when physical shaft couplings are used, since they allow a greater off axis error between the motor and driven shaft.

|

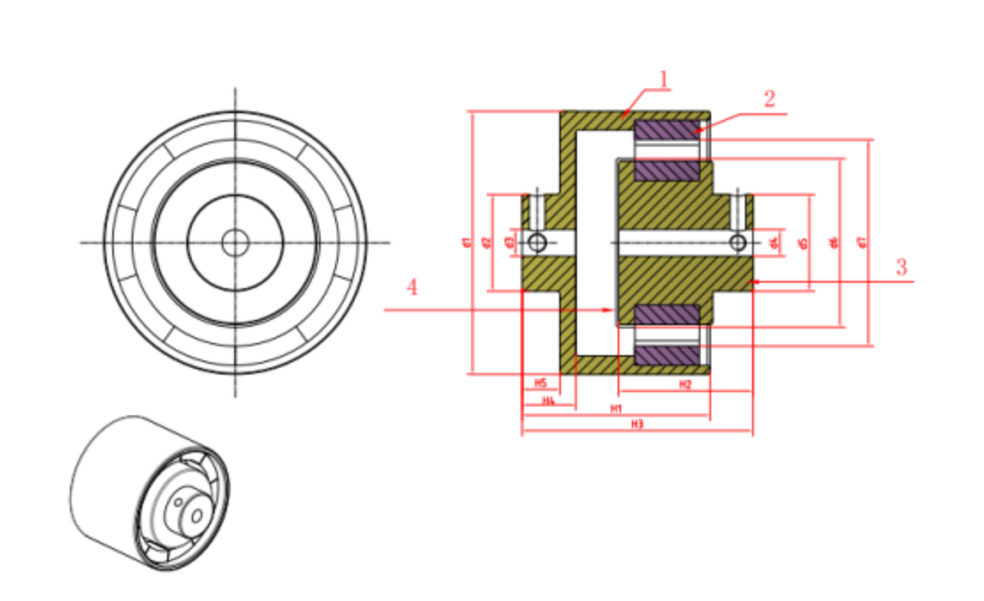

Item |

Description |

|

1 |

Outer Rotor |

|

2 |

Magnet |

|

3 |

Inner Rotor |

|

4 |

Spacer Sleeve |

1. Materials

Magnet: Neodymium Magnet

Sleeve: Austenite stainless steel, such as SS304, SS316.

Main part: 20# steel, martensitic stainless steel

2. Advantages

Magnetic coupling for standard applications

Hermetically sealed

No contact of torque transmitting elements

No maintenance necessary

High efficient can optional

3. Recommended applications

-Chemical industry

-Oil and g as industry

-Refining technology

-Pharmaceutical industry

-Centrifugal pumps

-Top drive mixers/agitators

4. How does magnetic coupling work?

Related Keywords