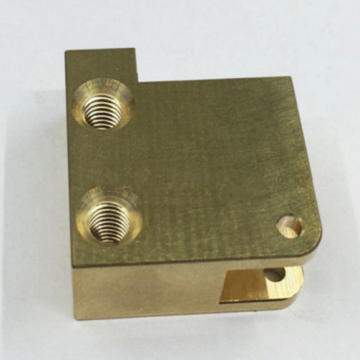

High Quality Brass Cnc Turning Dowel Pins

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, CIP

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Air

- Port:

- ChongQing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 100000 |

| Supply Ability: | 10000/week |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,CIP |

| Certificate: | IATF16949 |

| HS Code: | 8479909090 |

| Transportation: | Ocean,Air |

| Port: | ChongQing |

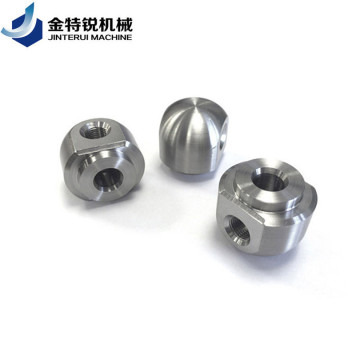

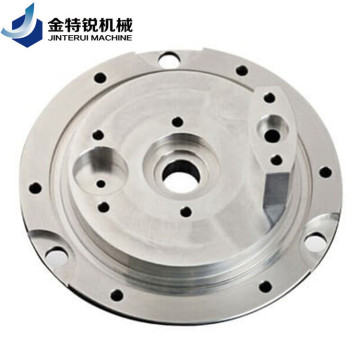

High Quality Brass Cnc Turning Dowel Pins

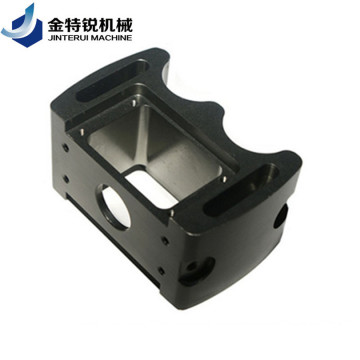

Milling & boring services are also available. Various industries served include automation, oil & pipeline & printing equipment, food processing, packaging & plastic processing machinery & conveying bulk & steel mills or steel processing. We have both turning and milling capabilities. With our CNC machines, we are capable of producing almost any shape of CNC milling parts. CNC milling is cost effective for short runs and complex shape, and it also possibles for high demand of precision tolerances.

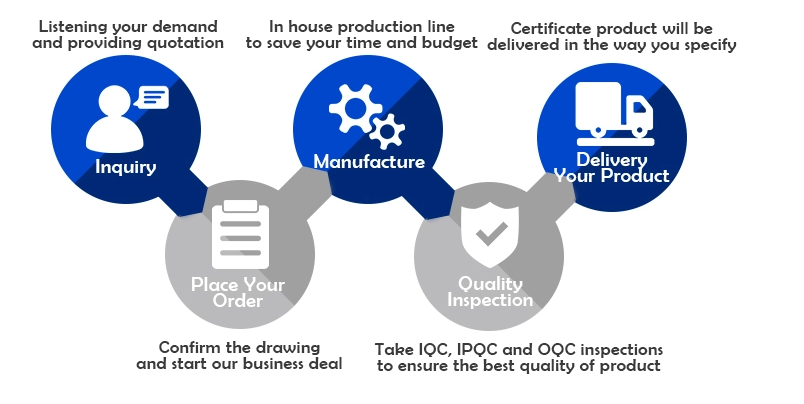

Business process

Application fields

Automotive, Automation, Test systems, Sensors, Medical, Sports, Consumer, Home appliance, Electronic, Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, etc

Material

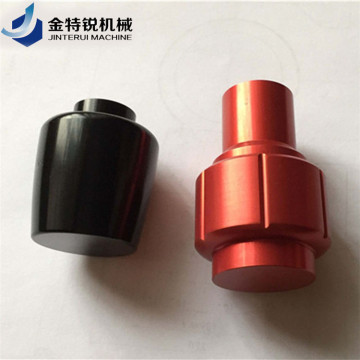

Aluminum:5052 /6061/ 6063 / 2017 / 7075 / etc.

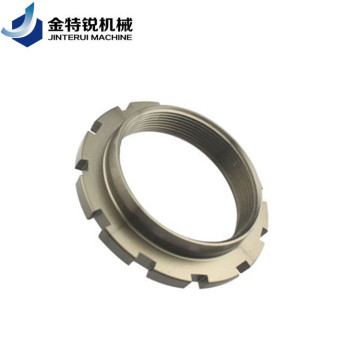

Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc.

Steel Alloy::Carbon Steel / Die Steel / Spring Steel/ Cold Rolled Steel etc.

Brass Alloy:3602 / 2604 / H59 / H62 / etc.

Die Casting Material: Aluminium

Alloy: ADC12/A380/A360/ZL101/ZL102/ZL114/etc

Zinc Alloy: Zamak 3/Zamak5/Zamak7/etc.

Surface Finishing

Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating.

Process

Drawing&Samples Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance

According to drawings

Equipment

Vertical Machining Center,Vertical Drilling Center,4-Axis Machining Center,Turning Machine,Drilling Machine,Sawing Machine,Hydraulic Press,Air Leak Tester,CMM

Preferred formats

JPEG,PDF,PNG,CAD,IGS,UG,Solidworks

Loading port

Chongqing

Delivery time

20-30 days after receiving orders,usually based on customers' PO QTY.

Note

Above item is only for your reference,not for sales;we only produce custom parts per customer` prints

Related products

Company Information

Certification

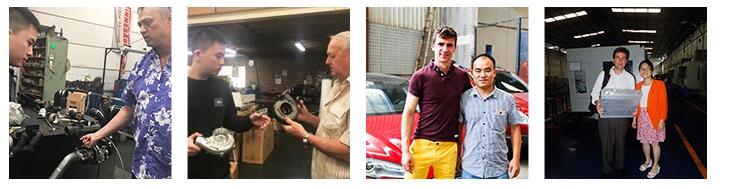

Our clients

Our products have been sold to more than 100 countries in the past 10 years.We have huge customer resources that is long-term Relations of cooperation.

Packaging &shipping

FAQ

1.What`s your warranty terms?

We will supply a replacement for parts that prove to be defective for a period of 18 months, starting on the machine`s bill of lading date.

2.what are our machining equipment?

The company owns more than seventy CNC machines including 8 sets 4-Axis CNC machining center.

3.Who are our mian customers?

BMW,ERICSSON,CHANA,ISUZU,LONCIN.

4.About our processing technology.

We will provide Die casting ,cnc machining,prototype parts.

Please kindly send us 2D&3D files for quote.

Related Keywords