Efficient custom metal rapid prototyping 3d printing

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Chongqing |

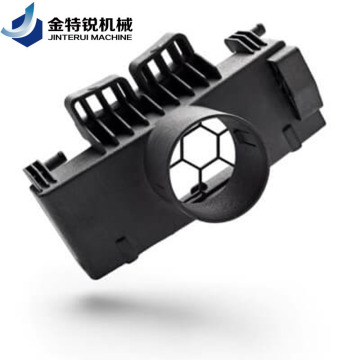

Product Name: Efficient custom metal rapid prototyping 3d printing

JTR has strong equipment strength and testing equipment strength, and its determination to provide quality products has been returned to customers.

The JTR machine is a specialized factory for custom CNC milling of steel parts. We can provide3d Lenticular Printing,3d Embossed Printing T Shirt,3d Floor Printing Machine. Our range of steel machined parts includes SS316 steel milled parts, CNC SS304 parts and more. Strong equipment, high-quality staff, professional certification, considerate service, let us become more than just a partner, we can become friends.

Type:3D printing

Materials:photosensitive resin

Color:begin colour

Standard:Plus or minus 0.1 mm

Material Aluminum: 5052, 6061,6063, 2017, 7075, etc

Stainless Steel Alloy: 303, 304, 316, 412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solid works

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

We provide high precision CNC machining parts service. Our parts ranges from CNC aluminum milling, CNC steel milling, CNC milled plastic parts.

Our Supplier Support

1. Raw Material: GB, ASTM Standard Profile and Metal Sheet

2. Casting: Aluminum Die Casting

3. Chemical Film: E-CLPS4600; Anodizing

4. SS Passivation

5. Anodize: Clear and Colored Anodizing; Hard Anodizing

We are sincerely looking forward to your visit and cooperation!

Related Keywords