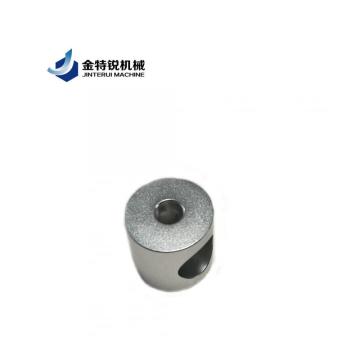

Polished round aluminum alloy die casting parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Chongqing |

Products Name:Polished round aluminum alloy die casting parts

Full service custom manufacturer of high volume aluminum die castings. Air set/no bake, aluminum sand, ductile/grey iron, centrifugal, ceramic mold, investment and vacuum casting, and aluminum permanent, gravity/tilt pour, low pressure, plaster and shell mold processes are available. Channel and coreless induction, drilling, shot blast finishing, vibratory and general polishing and fluidize bed nylon coating, painting, engineering and design and surface treatment services are also offered. Industries served include appliance, construction, electrical lighting, HVAC, industrial machinery, medical devices, sporting goods, automotive and aircraft/aerospace. Just-in-time delivery services are available.We can provide Die Casting Aluminum Frame, Die-casting Aluminum Led Cabinet, Aluminum Die Casting Housing Led, etc.

Process: Aluminum die casting

Application areas: automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, oil pump manufacturing, transmission machinery manufacturing, precision instruments, landscaping, power construction, building decoration and other industries.

Material Aluminum: 5052, 6061,6063, 2017, 7075, etc

Stainless Steel Alloy: 303, 304, 316, 412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

To protect your 3d files and other informations,we have taken two methods.

1.We could sign NDA with you as you required.

2.All of the computers in our company have installed confidential software.Without the password,no one could get access to the files.

We can cutomize metal cnc machining parts as per your drawing and techinical requirements.

We can also do surface treatment such as anodizing, polishing, powder coating, plating, and so on. Besides, our professional engineers can offer reasonable suggestion to your drawing and manufacturing technique. Metal machining capability provides unparalleled manufacturing flexibility. We utilize this flexibility to produce your prototypes faster and more economically.

Related Keywords