Custom aluminum die casting CNC machining

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Air

- Port:

- Chongqing

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Air |

| Port: | Chongqing |

Product Description

Product Description

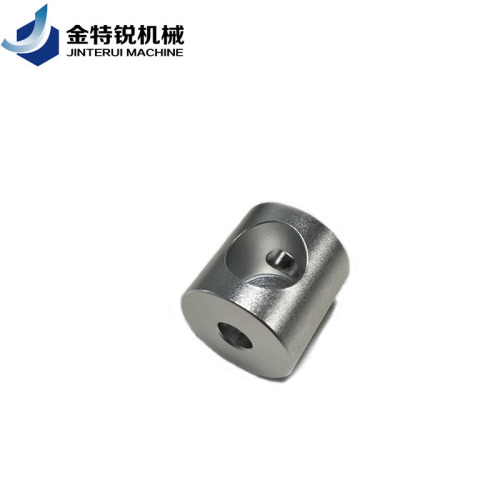

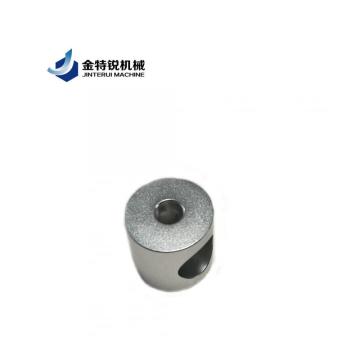

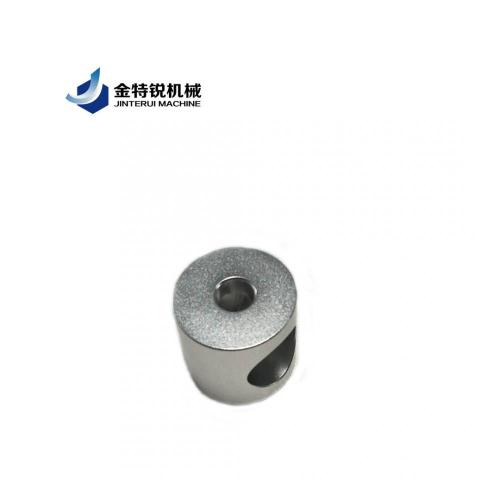

Products Name: Custom aluminum die casting CNC machining

Custom manufacturer of precision & non-ferrous die castings. Products include aluminum & zinc die castings. Aluminum die castings are available in alloys including 380 & 383. Specifications include plus /- 0.0025 tolerances & maximum molding weight of 10 lbs. Zinc die castings are available in standard alloys such as Zamak no. 3, Zamak no. 5 & Zamak no. 7 & hybrid alloys such as ZA-8 & ZA-27. Specifications include plus /- 0.001 tolerances & maximum molding weight of 4.5 lbs.

We can provide micro cnc turning machine, cnc turning wood and cnc lathe machinery turning.

Type:Aluminum die casting

Process: Aluminum die casting

Application areas: automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, oil pump manufacturing, transmission machinery manufacturing, precision instruments, landscaping, power construction, building decoration and other industries.

Material Aluminum: 5052, 6061,6063, 2017, 7075, etc

Stainless Steel Alloy: 303, 304, 316, 412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

Our company has established a group of senior professional and technical personnel to provide high quality and service to our customers.

1.Help customers optimize product design

2.Provide high quality products for customers

3.provide more perfect product process design for customer,make the product more beautiful and enhance the competition.

4.We will provide complete after-sales service for our products, and we also re-drawing for free pro5.duction if the product can`t meet the customer`s request

Related Keywords

Related Keywords