Machining black CNC milling parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Chongqing |

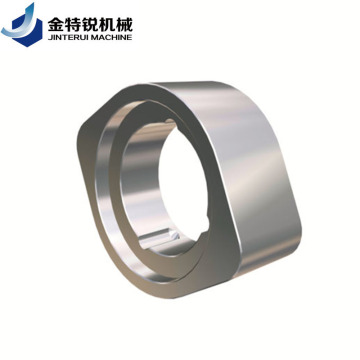

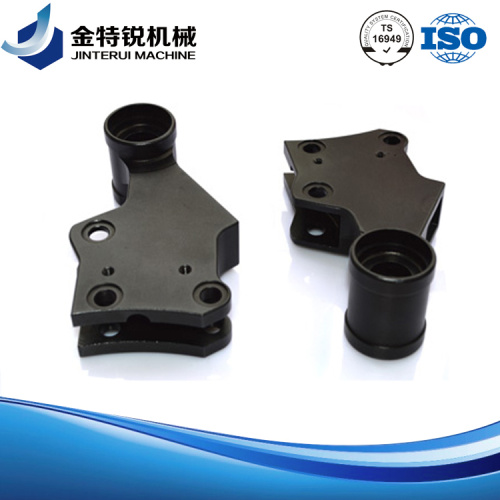

Products Name:Machining black CNC milling parts

Precision CNC vertical milling services. Materials handled include brass, alloy steel, aluminum, beryllium, brass, bronze alloys, carbon steel, copper, molybdenum, stainless steel, tin, titanium, tungsten, Inconel®, Kovar®, Monel®, laminated plastic, Delrin®, nylon, acrylonitrile butadiene styrene, acetal, acrylic, fiberglass reinforced plastics, nylon, polycarbonate, polyethylene, phenolic, PVDF & ceramic. Turning can be done to 0.0005 in. tolerances. Milled products include hydraulic fittings, fasteners, fittings, thread rods, sockets, bushings & spacers.

We can provide Cnc Milling Products, 3d Cnc Milling, Cnc Milling Processing, etc.

Type: CNC Milling

Surface treatment: electroplating

Scope of application: machine tools, automobiles, aircraft, etc

Material

Aluminum: AL5052, AL6061, AL6063, AL2017, AL7075, etc

Stainless Steel Alloy: SS303, SS304, SS316, SS412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

Our service

1. Design

At our enterprise ,we have many experts that can help with the design process. We are able to help you create drawings, reverse engineer parts, and do 3D/CAD drawings.

2. Die Casting

JTR has a partner die casting factory to get your castings done efficiently for both small lot or large capacity jobs.

3. JTR owns more than thirty CNC Machines including 8 sets 4-Axis CNC machining center and 6 years experience in metal machining to develop and process you parts.

4. Finishing

JTR knows that a part is not complete without finishing.We work with qualified finishing suppliers to get your product finished hassle-free.If you need to process parts, please contact us, our service can make you 100% satisfied!

Related Keywords