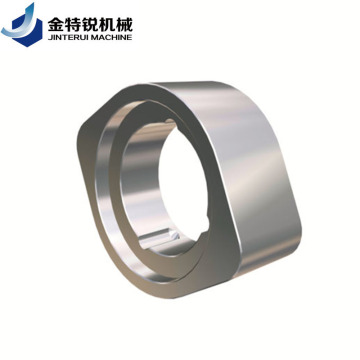

Custom rotary nut Cnc milling parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Chongqing

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Chongqing |

Product Description

Product Description

Products Name: Custom rotary nut nc milling parts

We can cutomize metal cnc machining parts as per your drawing and techinical requirements.

We can also do surface treatment such as anodizing, polishing, powder coating, plating, and so on. Besides, our professional engineers can offer reasonable suggestion to your drawing and manufacturing technique. Metal machining capability provides unparalleled manufacturing flexibility. We utilize this flexibility to produce your prototypes faster and more economically.

Type:CNC Milling, Precision Nonstandard Parts(OEM Service)

Main Material: Aluminium AlloyProcess: CNC milling, drilling

Application fields: Automotive, Automation, Test systems, Sensors, Medical, Sports, Consumer, Home appliance, Electronic, Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, etc

Material

Aluminum: AL5052, AL6061, AL6063, AL2017, AL7075, etc

Stainless Steel Alloy: SS303, SS304, SS316, SS412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

We are devoting ourselves to achieve high quality products, competitive prices and on-time delivery.

Related Keywords

Related Keywords