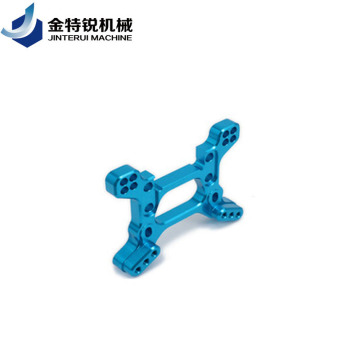

Custom machined aluminum Turning parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- CFR

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | CFR |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Chongqing |

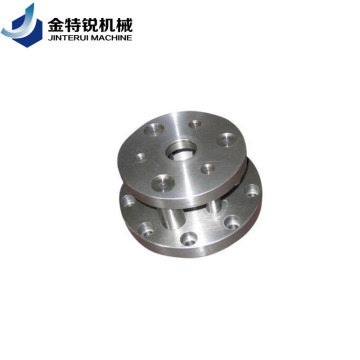

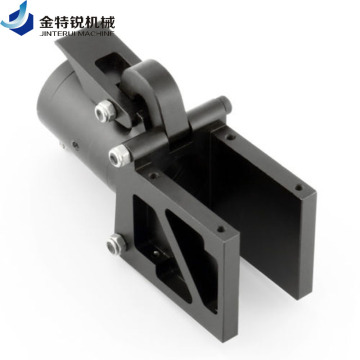

Products Name:Custom machined aluminum Turning parts

We can provide Cnc Wood Turning Machinery, Cnc Mini Wood Turning Lathe Machine, Turning Cnc Parts, etc.

Custom precision CNC horizontal and vertical turning services. Horizontal turning can be done up to 31.5 in. length and vertical turning up to 81.5 in. length with tolerances on parts up to +/- 0.0005 in. Materials handled include alloy steels, aluminum, brass, bronze, carbon steels, exotic metals, Hastelloy®, Inconel®, steel and stainless steel. Capabilities include 2, 3, 4 and 5 axis machining, horizontal and vertical drilling and milling, counterboring, countersinking, parting/cutting, facing, welding and fabrication. Markets served include aerospace, construction, defense/military, engineering, marine, industrial mining, nuclear power, oil and gas, rock crushing, spin tools, tanneries and wind energy. Emergency and rush services are available.

Process: CNC Turning

Application areas: Manufacturing industry, information industry, medical equipment industry, military equipment, other industries

Material Aluminum: 5052, 6061,6063, 2017, 7075, etc

Stainless Steel Alloy: 303, 304, 316, 412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

CHONGQING JIN TE RUI MACHINE Co.,ltd adhering to the "integrity-based, continuous innovation and the Pursuit of excellence" business philosophy, with a wealth of manufacturing experience, determined to provide quality products and solutions to give back to customers.

If you have any needs, please contact us immediately, we will provide you with the best quality service

Related Keywords