Machining of precision CNC turning plastic parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Chongqing

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Chongqing |

Product Description

Product Description

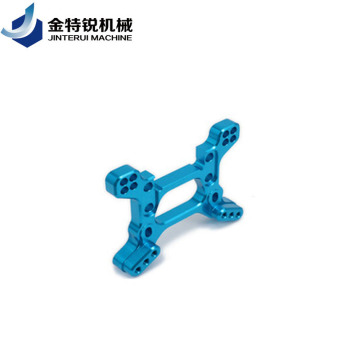

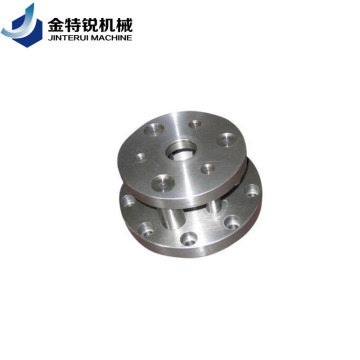

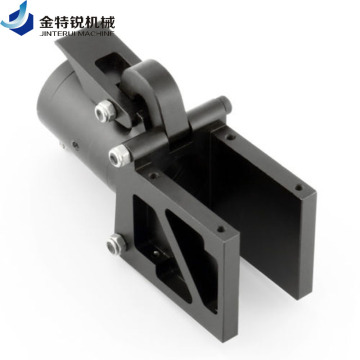

Products Name:Machining of precision CNC turning plastic parts

CNC metal precision turning services such as contour, form, taper, and straight turning. Part diameters range from 5/16 in. to 6 in. Max length, width, and height are 5 in., 7 in., and 7 in. respectively. Alloy steel, aluminum, brass, bronze alloys, carbon steel, copper and stainless steel materials used. Aerospace, agriculture, construction, automotive, electronic, electrical, medical, military and other industries served. NADCAP, ISO 9001:2008, AS9100, and TS 16949:2009 certified.

We can provide Cnc Turning Machine Report, Cnc Turning Tool Holder Types, Cnc Machine Turning Tools, etc.

Application areas: Manufacturing industry, information industry, medical equipment industry, military equipment, other industries

Material Aluminum: 5052, 6061,6063, 2017, 7075, etc

Stainless Steel Alloy: 303, 304, 316, 412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

We provide competitively priced quality products that satisfy our customer needs.around 5000-100000 squre meters warehouse and factory. more than 70 latest CNC Machining entre's.

1.Customize products according to customers` requirement.

2. First-rate machining equipment,ensure the quality of each process.

3. Low(1-2%)scrap rate 100% inspection(offer QC report).

4. Direct from factory.

Related Keywords

Related Keywords