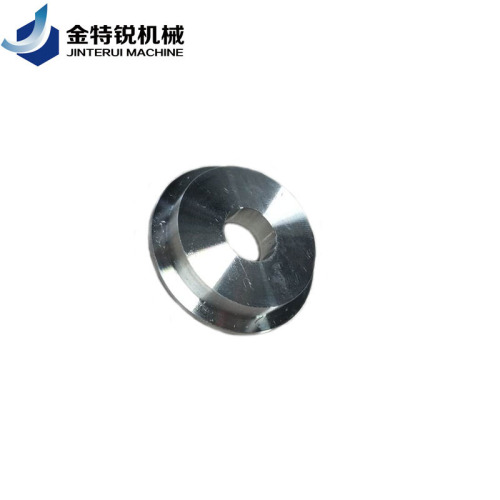

4 Axis CNC milling aluminum alloy rapid prototyping

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Chongqing |

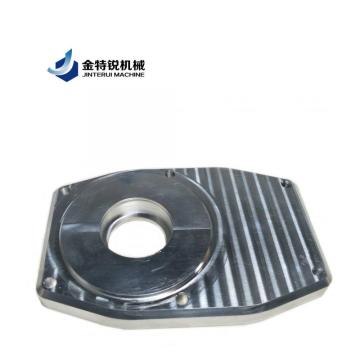

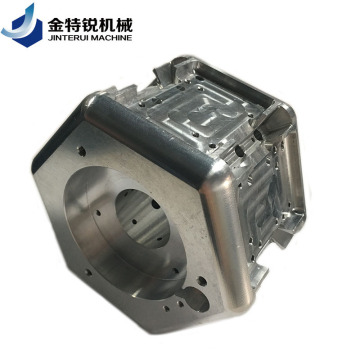

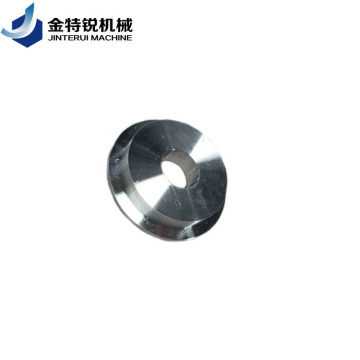

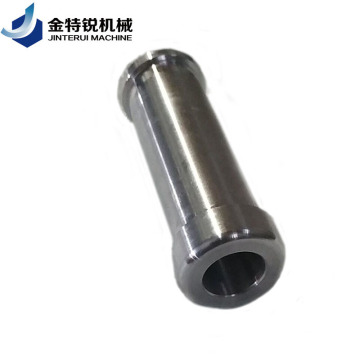

product name:4 Axis CNC milling aluminum alloy rapid prototyping

We can provide Cnc Motorcycle Part, Custom Cnc Machining Part, Cnc Lathe Turning Part, ect.

We are a national grade high-tech enterprise which professionally specialized in high precise injection parts, high precise machining parts and stamping parts. Our team have highly skilled manufacturing process for any complex parts, thin wall, micro parts, titanium alloy parts, peek parts etc especially, We provide total solution to customers including products design, molding design, DFM and manufacture, parts mass production and assembly [one-stop service". As an OEM factory, With the principle of "high-quality, efficiency, honesty and service", the aim of "sustainable operation, customers uppermost" and the good attitude of work and service, we are looking forward to building long-term and win-win business relationships with clients from all over the world.

Type:Papid CNC Prototyping

Material:Aluminum

surface treatment:Electrolytic Polishing

Application:Communication products,IT products,Household appliances,Instruments,Medical equipment,Industrial categories

Material Aluminum: 5052, 6061,6063, 2017, 7075, etc

Stainless Steel Alloy: 303, 304, 316, 412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solid works

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

Our clients

Our products have been sold to more than 100 countries in the past 10 years.We have huge customer resources that is long-term Relations of cooperation.

Our team

Our company has established a group of senior professional and technical personnel to provide high quality and service to our customers.

Our services

We provide OEM or ODM service for customers.

We provide one-stop service of customized aluminum alloy casting products

We can help clients design drawings and solve complex problems.

To protect your 3d files and other informations,we have taken two methods.

1.We could sign NDA with you as you required.

2.All of the computers in our company have installed confidential software.Without the password,no one could get access to the files.

If you have any needs, please contact us immediately, we will provide you with the best quality service

Related Keywords