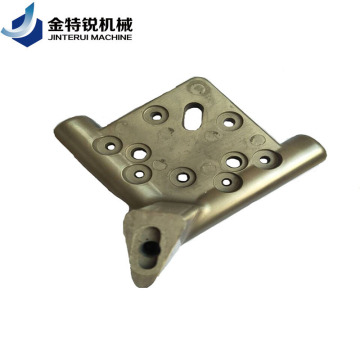

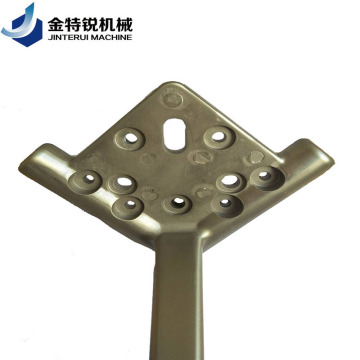

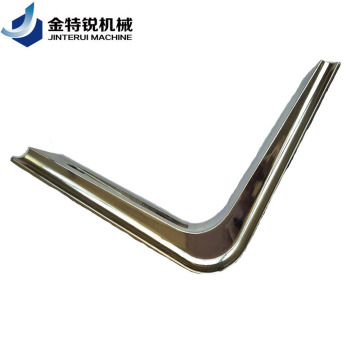

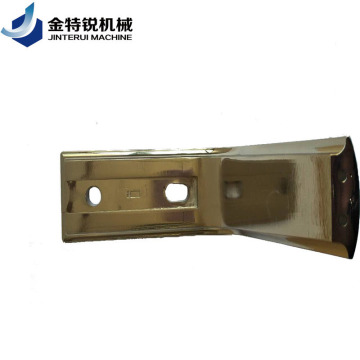

Custom Service Zamak Die Casting Part

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- ChongQing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | ChongQing |

We are a factory providing high precision CNC machining parts service.

We adhere to the "honesty, innovation, the pursuit of excellence" business philosophy, with rich manufacturing experience, determined to provide customers with quality products and solutions.

Zamak Zamak die-casting service

Materials: Zamak2, Zamak3, Zamak4, Zamak5

Zamak die casting process

Product solution: lock hardware furniture accessories auto accessories machinery and equipment accessories doors and Windows hardware accessories bathroom accessories other accessories

Materials: aluminum, 5052,6061,6063,2017,7075, etc

Stainless Steel Alloy: 303, 304, 316, 412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing:

Anodizing, Bead Blasting, Hard Coat Anodizing, Heat - treating, Induction Heat treating, Laser Etching, Pad Printing, Painting, Parkerizing, Plating, Polishing, Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining- Surface treatment-Assembly-Quality inspection-Packing-Shipping

How: "According to drawings.

Equipment: vertical machining center, vertical drilling center, four-axis machining center, lathe, drilling machine, sawing machine, hydraulic press, air leakage tester, CMM

Preferred formats: JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: chongqing

Delivery time: 20-30 days after receiving the order, usually according to the customer's PO quantity

Note: the above items are for reference only, not for sale.

We only produce parts according to customers' drawings

Company strength:

The company actively expands the business market, the product touch extends to automobile, motorcycle, communication, military industry and other industries, some products are exported to southeast Asia and Europe and the European market.

At present, the company mainly serves German BMW large displacement motorcycle, Ericsson communication base station, chaoyang heavy diesel engine, zong shen tong machine, changan automobile shares, qingfeng automobile shares and other customers.

Equipment strength:

The company has more than 70 sets of various types of precision CNC processing equipment, equipped with three axis, four axis machining center, drilling attack center, CNC lathe (Japan five axis double spindle milling compound, four axis double spindle milling compound, four axis double spindle walking center, common bed body).

There are more than 10 lathes, milling machines, drilling machines, grinding machines and other common machine tools, 2 sets of 500t-1000t precision cold chamber die-casting machines, all the equipment annual processing capacity can reach millions.

Testing equipment:

Our company has high precision Hexcon CMM CMM three-coordinate detector, projector, roughness meter, profiler, pneumatic meter and other general precision measuring instruments and special testing tools, to ensure that the product in the sample development, pilot production and various stages of mass production to meet the different needs of customers.

Related Keywords