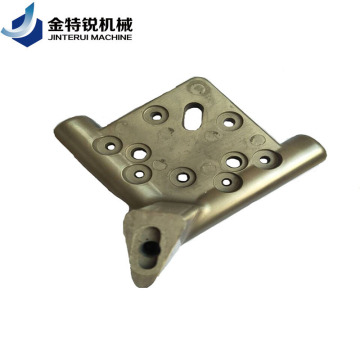

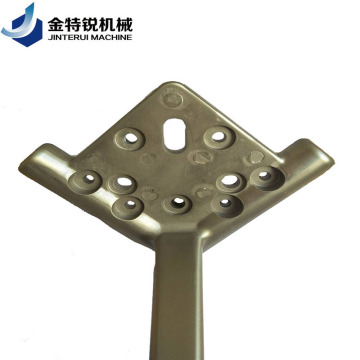

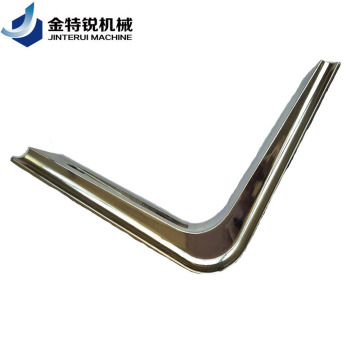

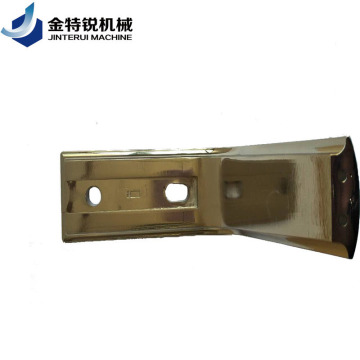

Customized Precision Zamak Die Casting parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- ChongQing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ChongQing |

|---|---|

| Productivity: | 30000 |

| Supply Ability: | 10000/week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | IATS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | ChongQing |

Chongqing jin te rui machinery co., ltd. adhering to the "honesty, innovation, the pursuit of excellence" business philosophy, with rich manufacturing experience, determined to provide customers with quality products and solutions.

If you have any requirements, please contact us immediately, we will provide you with the best quality service

Product name: customized precision Zamak die-casting parts

Type: Zamak die casting

Materials: Zamak 3 / Zamak 5 / Zamak 7

Applications: turbine blades, weapon parts, pipe fittings, locking parts, hand tools

Material: aluminum, 5052,6061,6063,2017,7075, etc

Stainless steel alloy: 303,304,316,412, etc

Steel alloy: carbon steel, die steel, spring steel, cold rolled steel, etc

Brass alloys: 3602,2604, H59, H62, etc

Other special materials: copper, plastic, plexiglass, nylon, phenolic plastic, carbon, PP, PC, PE, PEEK, titanium, etc

Surface treatment: anodic oxidation, bead sandblasting, hard coating anodic oxidation, heat treatment, induction heating treatment, laser etching, pad printing, painting, Parkerizing, electroplating, polishing.

Powder coating, precious metal plating

Process drawing and sample - die making - die casting - deburring - drilling and threading - nc machining - polishing - surface treatment - assembly - quality inspection - packaging - transportation

Tolerance: according to the drawing.

Equipment: vertical machining center, vertical drilling center, four-axis machining center, lathe, drilling machine, sawing machine, hydraulic press, air leakage tester, CMM

Preferred formats: JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: chongqing

Delivery time: 20-30 days after receiving the order, usually according to the customer's PO quantity

Note: the above items are for reference only, not for sale.

We only produce parts according to customers' drawings

Our services

1. Help customers optimize product design

2. Provide high-quality products for customers 3

Provide more perfect product process design, make the product more beautiful, enhance competitiveness.

4. We will provide complete after-sales service for our products. If the products cannot meet the requirements of customers, we will provide free pro5 duction again.

Related Keywords