Sink hydraulic press

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF, EXW, CIP

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF,EXW,CIP |

| Transportation: | Ocean,Land |

Sink Hydraulic Press

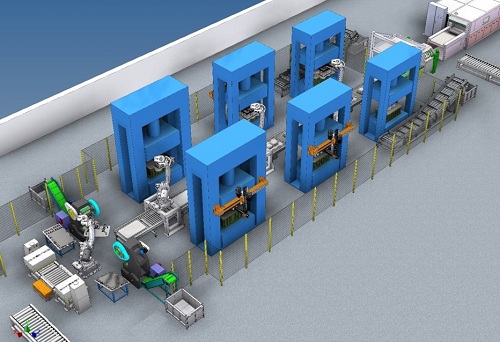

Automatic sink production line: It refers to the automatic production line of steel coil uncoiling, cutting and blanking, stamping and forming processing.

Automatic sink production line consists of two parts: material supply unit and sink stamping unit. Between those two parts by the logistics transport unit to carry out. The material supply unit is composed of uncoiling, laminating, leveling, shearing and stacking equipment. The logistics conveying unit is composed of transplanting trolley, stacking buffer line and empty pallet buffer line. The pressing unit is composed of a press machine and a robot automatic line with four working procedures: the first corner cutting, the first stretching, the second stretching and the cutting edge.

The production capacity of the production line is 2 pieces/minute and annual output is about 230,000 pieces.

Basic Info:

Model No.: YJK27 series

Type: Four-Column & Frame type Hydraulic Press

Feature: Automation, Precision, High Efficiency

Certification: ISO9001; CE

Condition: New

Customized: Customized

Warranty: 24 Months

Additional Info

Productivity: 5 Sets/Month

Brand: Jiangdong

Place of Origin: China

Supply Ability: 5 Sets/Month

Product Description

Performance Characteristics:

Automatic sink production line consists of two parts: material supply unit and sink stamping unit. Between those two parts by the logistics transport unit to carry out. The material supply unit is composed of uncoiling, laminating, leveling, shearing and stacking equipment. The logistics conveying unit is composed of transplanting trolley, stacking buffer line and empty pallet buffer line. The pressing unit is composed of a press machine and a robot automatic line with four working procedures: the first corner cutting, the first stretching, the second stretching and the cutting edge.

The production capacity of the production line is 2 pieces/minute and annual output is about 230,000 pieces.

Applicable fields:

Automatic sink production line: It refers to the automatic production line of steel coil uncoiling, cutting and blanking, stamping and forming processing.

Specification:

|

Model |

Unit |

YJK27-SF400 |

YJK27-SF630 |

YJK27-SF800 |

YJK27-SF1300 |

|

|

Capacity |

kN |

4000 |

6300 |

8000 |

13000 |

|

|

Stroke per min |

SPM |

6 |

6 |

6 |

6 |

|

|

Return force |

kN |

560 |

720 |

810 |

1050 |

|

|

Max. Pressure |

MPA |

25 |

25 |

25 |

25 |

|

|

Slide Stroke |

mm |

1400 |

1400 |

1400 |

1400 |

|

|

Open height |

mm |

2000 |

2000 |

2000 |

2000 |

|

|

Slide |

Rapid down |

mm/s |

600 |

600 |

600 |

600 |

|

Press 1 |

mm/s |

≥100 (150T) |

≥100 (220T) |

≥100 (300T) |

≥100 (500T) |

|

|

Press2 |

mm/s |

≥50 (250T) |

≥50 (400T) |

≥50 (500T) |

≥50 (800T) |

|

|

Press3 |

mm/s |

≥30 (400T) |

≥30 (630T) |

≥30 (800T) |

≥30 (1300T) |

|

|

Return |

mm/s |

≥500 |

≥500 |

≥500 |

≥500 |

|

|

Worktable size |

L-R |

mm |

3400 |

3400 |

3400 |

3400 |

|

F-B |

mm |

2000 |

2000 |

2000 |

2000 |

|

Certificates:

Configurations of main components:

|

Name |

Brand |

Configuration |

Name |

Brand |

Configuration |

|

Circuit Breaker |

Schneider, France |

S |

Security Light Curtain |

SENSORC, China |

S |

|

Thermal Relay |

Schneider, France |

S |

Motor |

Quality product, China |

O |

|

Intermediate Relay |

Schneider, France |

S |

Oil Pump |

Quality product, Taiwan |

O |

|

Power Source |

Schneider, France |

S |

Hydraulic Valve |

Tian Li, Beijing |

O |

|

Button |

Schneider, France |

S |

Sealing Element |

NOK, Japan |

S |

|

Time Relay |

SIEMENS, Germany |

S |

PLC |

MITSUBISHI, Japan |

O |

|

Transformer |

Bright, Wuxi |

S |

TPC |

MCGS, China |

O |

Notes: S stands for standard configuration, and O stands for optional configuration

Forming solution:

Jiangdong machinery has been committed to understanding and matching customer needs, to provide customers with a "one-stop" overall solution, has become the pursuit of Jiangdong machinery goal. Therefore, Jiangdong machinery in addition to be equipped with high precision in hydro-forming equipment, safer, more reliable, and to hydro-form equipment production line automation, intelligent, flexibility, gather the automotive light weighting forming technology research and development, and in material, forming technology, mould, fixture, constantly explore accumulating core technologies such as a "turnkey" project, And to ensure that the production efficiency, forming accuracy, processing costs and other aspects of comprehensive competitiveness, and customers to achieve win-win, mutual benefit, common development.

Technical support:

Jiangdong Machinery as a customer to provide a full range of technical support is obligatory responsibility. Technical support includes pre- and after-sales support. Pre-sales technology is mainly used to fully identify the material, process, mold and equipment requirements of the customer for the production of product parts, and to achieve an organic combination, so as to improve efficiency, control quality and reduce operating costs. After-sales technical support includes operation and maintenance training, equipment maintenance items and requirements, so that customers can fully and efficiently use the equipment functions. Each customer can take advantage of our online technical assistance, submit questions and requests, and receive responses in real time.

Spare Parts:

When the Jiangdong machinery products leave the factory, according to the structure or feature of the equipment, equipped with regular wearing parts and spare parts; When the equipment needs to be replaced with spare parts, Jiangdong machinery purchases from our partner suppliers to ensure that each customer can recover the spare parts needed for the operation of the equipment in a very short time, whether within or outside the warranty period.

Maintenance:

Jiangdong machinery attaches great importance to the maintenance of products purchased by users, and quickly solves the equipment problems through our offices or partners around the world.

Remote service:

Through the Internet, under the premise of customer authorization, Jiangdong machinery can understand the status of customer equipment and provide remote diagnosis and service, without requiring our engineers to the plants for maintenance or modification of procedures, so as to shorten service time and achieve rapid response.

Training:

Training is also one of most important services for us. Train equipment operation and maintenance personnel for customers. The training content includes equipment operation principle, operation rules, safety key points, maintenance items and plans, major troubleshooting and other contents. The training site is usually the customer equipment installation plant. Through training, customers can fully understand the use and maintenance equipment.

Related Keywords