Overhead loading and unloading conveyor for powder coating line UH-5075-S

- Min. Order:

- 100 Meter

- Min. Order:

- 100 Meter

Your message must be between 20 to 2000 characters

Contact NowProduct Name: Overhead loading and unloading conveyor for powder coating line

UH-5075 series conveyor chains have excellent extensity and capable of making any turn on both horizontal planes and vertical planes. Based on the actual needs of various process flows, the conveyor has been deliberately designed to run across relatively long routes and abstruction objects to transmit the work pieces along the scheduled route all the way to their destinations. In this way, UH-5075 can integrate all separate production steps into an automatic production line, which has greatly improved efficiency and product quality level and strengthen the management as well.

Specification of Overhead loading and unloading conveyor for powder coating line

|

MODEL ITEM |

UH-5075-S Standard chain |

UH-5075-HH Heavy-duty chain

|

UH-5075-HV Heavy-duty chain |

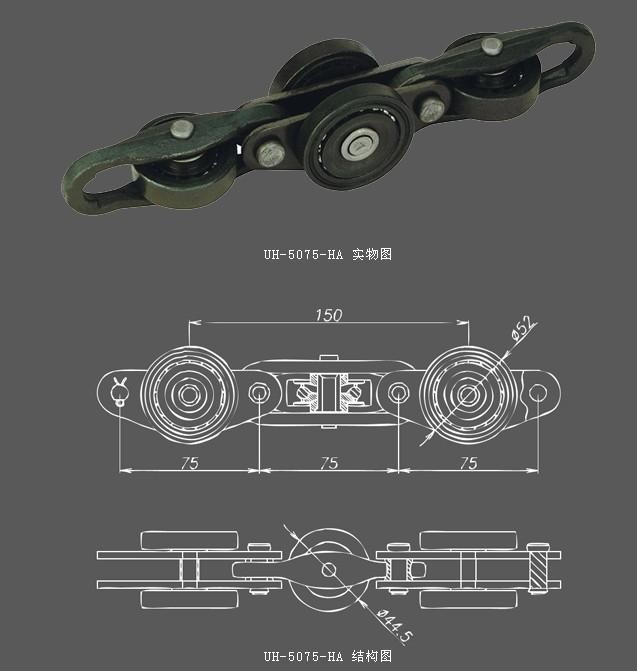

UH-5075-HA Heavy-duty chain |

|

Suspension Spacing (mm) |

150+(150× N) |

150+(150 × N) |

150+(150 × N) |

150+(150 × N) |

|

Chain's Weight (kg/m) |

4.2 |

4.58 |

4.83 |

5.3 |

|

Single-span Weight (≤kg) |

35 |

40 |

45 |

50 |

|

Chain's Allowed Pull Force (≤kgf) |

3000 |

3000 |

3000 |

3000 |

|

Chain's Catastrophic Pull Force (≥kgf) |

5500 |

5500 |

5500 |

5500 |

|

Working temperature (≤°C) |

250 |

300 |

300 |

400 |

|

Applicable Equipment |

General conditions |

Large bending; High temperature; |

High temperature; Heavy work piece; Frequently lifted; |

High temperature; Heavy work piece; Complicated route; |

|

Material |

16# Medium-carbon steel, Steel A3 |

|||

|

Remark: The above technical data is for our usual hanging type conveyors: UH-5S, UH-5HH, VH-5HA type. We can customize design and manufacture the products based customers particular requirements. |

||||

Drawing of Overhead loading and unloading conveyor for powder coating line

Advantages of Overhead loading and unloading conveyor for powder coating line:

- Low noise

- Less power consumption

- Stable operate performance

- User-friendly and safe use

- Excellent extensity

- Make full use of space

- Large angle bending space

- High mechanization & automatization

- Close -up continual conveying equipment

- Work perfectly together with the ground facilities

- Make any turns on both horizontal plane and vertical planes

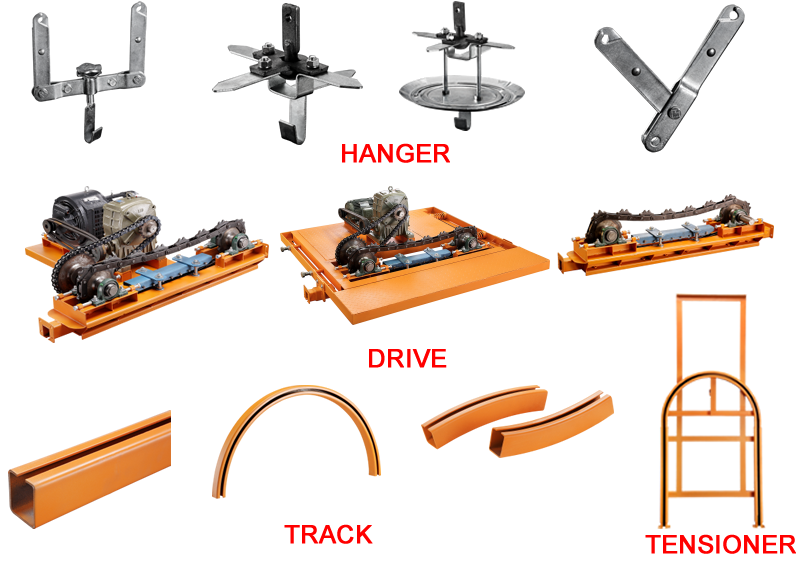

Other spare parts for Overhead loading and unloading conveyor for powder coating line:

Track: Straight track, Bush track,Vertical track, Horizontal Track

Driver Device:Limit-load Caterpillar Driver Device, Caterpillar Driver Device, Sprocket Driver

Take up Device:Heavy Bob type take up device

Hanger:Cross type disk hanger, sprocket wheel hanger, Y type hanger, Cross type hanger, electroplating hanger,

U type Hanger,Bearing hanger

Other Accessories: hanger turner, track flange, track install hanger,check track, Manual /automatic oil feeding cup

Automatic oil sprayer

Application of Automatic mini overhead conveyor system UH-5075

Conveyor chain is closeoop continual conveying equipment widely applied for continual convey of various industrial work pieces,

such as surface treatment, powder coating, paint spraying, drying, oven, cooling room and plaing the finished products off the line, furniture factories, bicycle plants,electronic products factory, hardware factory.

- Chain Material:16# Medium-carbon steel, Steel A3

- Track material: Steel A3

- The drive system better to be 5~7 meters after the adjust seat

- If dont move, check if any straight and curve rails; check the motor and chain; check if use high temperature chain lubricant

- If chain fall of the drive, check the driving wheel

We have professional engineer to design you a whole overhead conveyor chain line.

Miss Kathy Tang

Mobile, Wechat, What's app: 0086-18423473470

Skype: tyc9744

Related Keywords