Heavy Duty Overhead Enclosed Track Conveyors

-

$21.00≥40 Meter

- Min. Order:

- 1 Meter

- Min. Order:

- 1 Meter

- Transportation:

- Ocean

- Port:

- Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000 Meter/Meters per Month |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean |

| Port: | Guangzhou |

Heavy Duty Overhead Enclosed Track Conveyors for Industrial Applications

Specifications

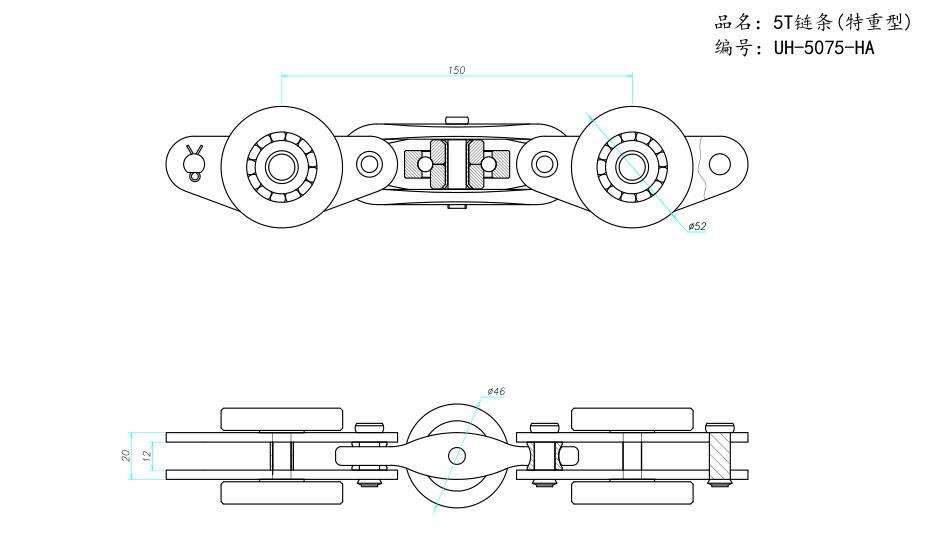

Model:UH-5075-HA(5 Ton)

Separation of suspension:150+(150*N)

Chains weight:5.3 kg/meter

Single loading weight:≤50kg

Max taken pull force:3000 kg/f

Max working temperature:400 degree

Breaking strength:5500 kg/f

Features:

1.Chain horizontal and vertical wheel switch to medium carbon steel forging wheels and bearing steel ball, to improve its bearing capacity and wear resistance, reduce the chain tensile deformation, extend the service life of the chain.

2.Fits for more turning conners, smaller radius of rotation, Hanging more heavy parts, lifting the location of more lines. Particularly suitable for use in environments with relatively high temperatures.

About the traditional 5T chain:

At present, the traditional 5T conveyor chain (UH-5075) is the most widely used with largest sales number in overhead conveyor. The chain has the small pitch can run small curved track. Also it’s hanging more workpiece, many kinds of type for choice, great varietyof chain accessories and installation is easy. The 5T chain has always been the first choice of overhead conveyor. But this chain has gone through more than 60 years in the market. No matter in the produceing materials, processing methods and parts structure all have the very big improvement space.

For example, the transmission of 5T traditional conveyor chain has a defects, when the driver gear shifting gear and chain buckle arc surface touch driver unit. That will creating a downward pressure to cause the driver unit’s pressing plate (Pressing device) and bottom plate damage. And complex chain components to making the tolerance increase, processing tedious and difficult assembly then increase chain manufacturing difficulty.caused the occurrence of defective parts. Effect of conveyor operation and using life of chain. We created UH-7075 5T cross type overhead conveyor chain. According to the traditional 5T chain for overall reform, Is not only change the new appearance, The most important is the mechanical properties are greatly improved.

The features are as below:

1. The perfect compatibility with traditional 5T accessories: The driver unit, horizontal curved track, vertical curved track and hanger are 100% compatibility with traditional 5T conveyor.

2. More streamline of shape and structure: Strengthened the steering structure: Forging cross-head as main part of steering, so the chain to become a real universal structure. When the chain conveying to the horizontal & vertical track, the chain would not distorted and offset the track. Also reduce the wear and resistance.

3. The tensile strength increased dramatically: Except the chain wheels & rivet which are independent of tensile strength.All the other parts are made of middle carbon steel in model S45C with quenched hardening treatment. The chain would not deformation in strong tension and the conveyor chain reduce the elongation about 50%.

4. Efficient design of driving: Improved the chain’s transmission of structure, to reduce the component force substantially of driving direction. And make the driver gear more efficient to pushing the chain, so the conveyor line running more fluent, energy saving and the using life of driving unit also extend. 5. Lightweight, flexible and more energy saving: The new 5T cross-type chain, improve the old problems and strengthen many mechanical properties. While also reducing the weight of 8% to reduce the force of chain, the load of conveyor motor becomes small and less power consumption, The design fully meet of environmental protection and energy saving. UH-7075 chain in all respects with excellent performance. It is the best choice of overhead conveyor chain.

We also offer as followed for whole overhead enclosed track conveyors systems

Finishing tunnel conveyor,Drive Unit,Take up unit,Enclosed track,Enclosed track curve,Dust shield,Track fasteners(track flanges and support flanges),Lubrication systems and load bars.

Application

The overhead enclosed track conveyor is used in two main areas, decorative and industrial.

Industrial applications:

Production lines,Assembly lines,Automated sorting systems,Paint shop lines,Automated dynamic storage, etc

Decorative applications:

Restaurants,Bars,Museums,Retail stores,Exhibitions,Grocery stores, etc

Technical support related instructions

User line design, generally should have the following information:

1.Workpiece dimensions and single piece weight;

2.Workpiece hanging method and the distance from the structure;

3.Process flow and the points elevation;

4.The speed of the workpiece;

5.The relevant building structure information;

6.The relationship between the single point of hanging and the hanging distance

In this manual, the single point of lifting in the main technical parameter item refers to the weight of the permissible hanging weight for every two objects (including the distance). If an object is required for each pitch, Can hold the specified value of half the weight. If the hanging object is separated by more than three piers, and its hanging weight and more than the rated single point of hanging, you can use double-point beam hanging version.

7.The relationship between single point hoisting and support span

In this manual, the single point of lifting in the main technical parameter item refers to the value of the supporting distance of 4 meters in the conveying track. If the supporting distance is 5 meters, the single point hoisting is only 40% of the specified value, ; If the support spacing of 6 meters, then allow a single point of hanging only 20% of the specified value.

When arranging the hanging material spacing, it is necessary to ensure that there is sufficient clearance between the hanging objects, especially the horizontal turning and the downhill section, to ensure that there is no collision between the hanging objects or hanging objects and other objects

8.The operating speed must meet the process requirements

In the following table, the running speed of each type of driving device is available. Considering the working efficiency of the motor and the requirement of the variable speed range, the optimum process speed is usually selected from 60% to 80% of the high speed of the conveyor should.

9.Chain up force check

In order to ensure the safe use of hanging conveyor, in the design of the line must be the maximum tension of the conveyor chain to check the safety, requiring the maximum tension of the chain, generally not greater than the main technical specifications provided in the allowable tension, the maximum chain tension Of the calculation method in the lifting transport machinery manual can be found, the calculation of the approximate formula:

Where: Smax - traction to build the maximum tension (kg)

f - transmission line average walking resistance coefficient

L - conveyor length (m)

W1 - Average weight of the spreader for the whole line (kg)

W2 - Starting load (kg)

S0 - Initial tension of the tightening device (kg) General S0 = 30kg

K - the total drag coefficient of the initial tension

N - the number of horizontal and vertical elbows converted to 90 degrees

K = (1.05 - 1)

The numerical value of the friction coefficient in the calculation formula is closely related to the structure of the conveyor chain, the span of the conveying rail, the driving, the tightening and the quality of the rail installation, lubrication and environmental conditions. In general, the support of small span, the installation of good quality, lubrication and good environmental conditions of the ball wheel chain desirable smaller coefficient of friction. When the calculation of Smax is greater than the main technical specifications in the provisions of the allowable tension, the running line can be designed as a dual machine or more children do not drive, we can provide users with multi-machine driver supporting technical services.

Thank you for your reading!

For more information,please send us inquiry.

Related Keywords