High efficiency and gas saving Industrial tunnel oven Infrared Gas burner

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Chongqing, China

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000 Unit/Units per Year depending on the customer require |

|---|---|

| Payment Type: | L/C,T/T,Paypal |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Chongqing, China |

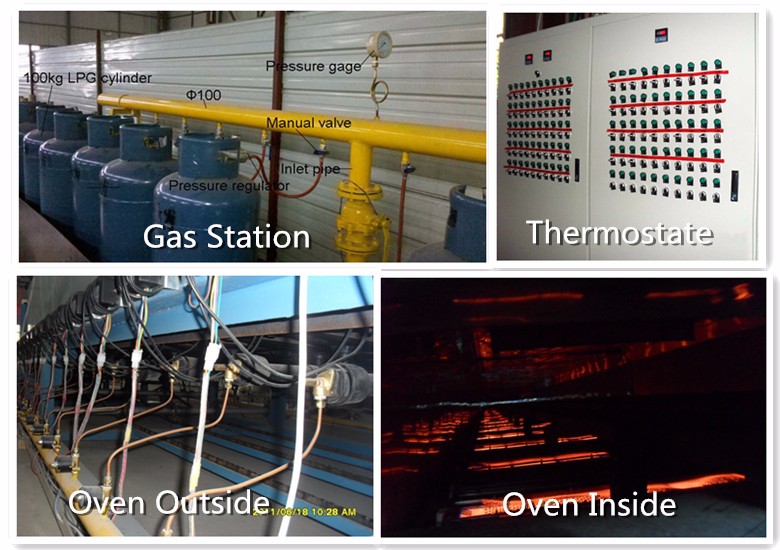

There are three ways to transfer heat, Radiation, Convection, Conduction and their thermal efficiency decrease in turn. Most Equipment is mainly by convection to heat air first and then, the heated air transfer to object. Heat loss is big. But, differently, infrared gas burner heat object directly by radiation and transfer rate will be much higher, usually it can save 20% gas energy and cost.

Infrared Catalyst Industrial Gas Burner Catalogue | ||||||||||||||

MODEL | Dimension | Weight | Gas Type | Heat Output | Consumption | |||||||||

mm | kg | KW/h | Kcal/hr | NG(m3/h) | LPG(kg/h) | |||||||||

HD61 | 423*80*94 | 3.8 | NG/LPG | 2.4 | 2030 | 0.18 | 0.18 | |||||||

HD82 | 219*164*108 | 4.8 | NG/LPG | 3.1 | 2700 | 0.24 | 0.24 | |||||||

HD101 | 690*80*115 | 6.9 | NG/LPG | 3.9 | 3380 | 0.3 | 0.29 | |||||||

HD162 | 570*130*175 | 8 | NG/LPG | 6.3 | 5400 | 0.49 | 0.47 | |||||||

HD410 | 410*175*220 | 8 | NG/LPG | 6.3 | 5400 | 0.49 | 0.47 | |||||||

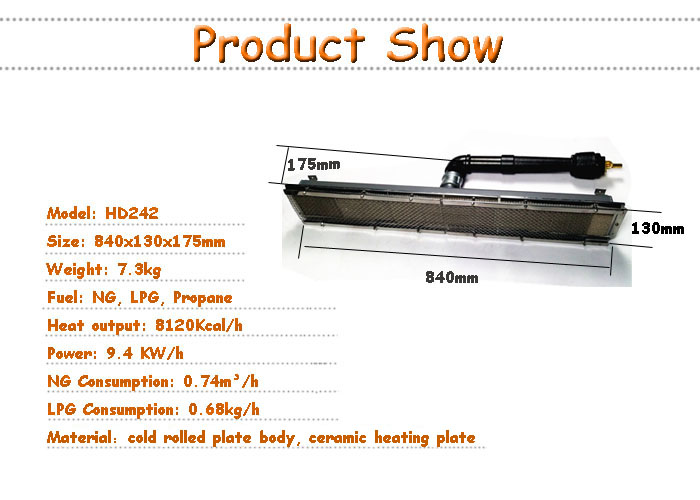

HD242 | 840*130*175 | 11.7 | NG/LPG | 9.4 | 8120 | 0.75 | 0.71 | |||||||

HD600 | 600*175*220 | 11.7 | NG/LPG | 9.4 | 8120 | 0.75 | 0.71 | |||||||

HD262 | 930*130*175 | 13 | NG/LPG | 10.9 | 9360 | 0.8 | 0.82 | |||||||

Our Infrared Catalyst Industrial Gas Burner Advance

1. Widely used in low pressure (below 6 Kpa)

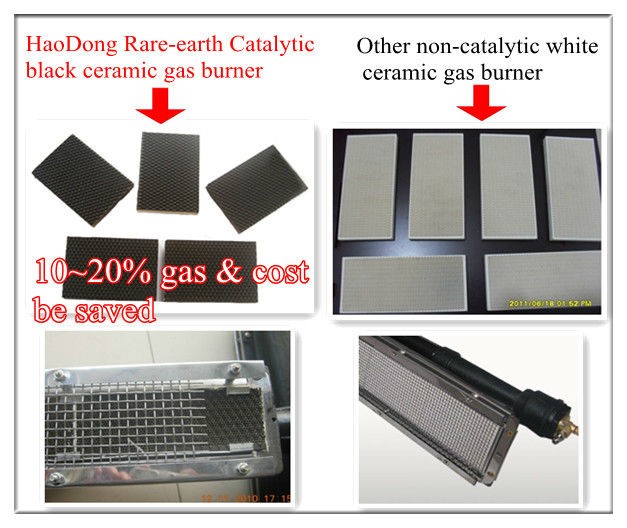

2. Adopting advanced technology of rare-earth catalyst on ceramic plate, about 10%~20% gas consumption

will be saved.

3. Low gas consumption.

4. Even heating,

5. Much cheaper than metal fiber burner

6. Single product has separate control system, it will not influence work of each other

7. Flameless combustion, also suitable for powder products baking process

Energy saving:conversion rate:≥90%

Environmental protection:CO≤80ppm;NOx≤10ppm;CHx≤50ppm

Taking full usage of heat:95% of energy released in the form of infrared ray ;heating the objects directly

Long life:≥11000hr

Easily installed

Notice

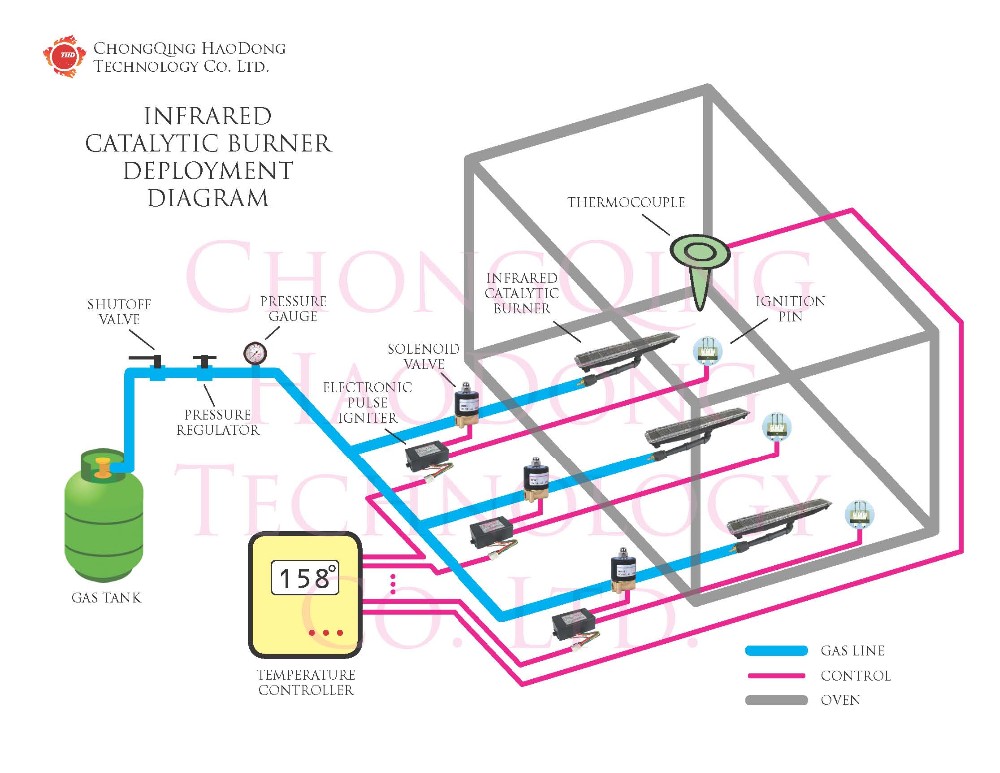

1. The inside casing measurement of oven should be confirmed when choose infrared catalytic burner model.

2. The intake-tube (or air blast pipe) and shell body can't be installed in the oven but bared in the air.

3. It is gas & air pre-mixed type, if baring air damper into air is unavailable, pls leave some hole for enough air in.

It needs to leave a 4-5cm space between oven wall and ignition pin for maintenance; Also keep the pinpoint distance from burner ceramic surface 2~5mm.

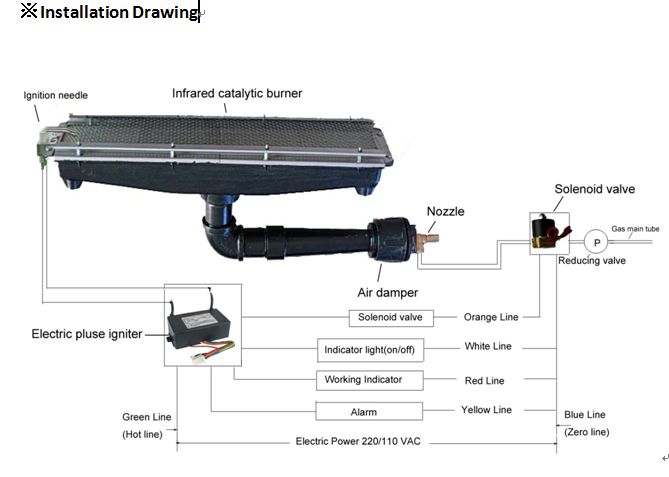

4. A set of standard configuration of infrared catalytic burner is infrared catalytic burner + ignition needle + pulse ignition + solenoid valves.

5. Any installed position is ok, but when the burner is on top or side, you should keep a 15° gradient between the wall and burner ceramic surface so that the heatwave will rise up smoothly.

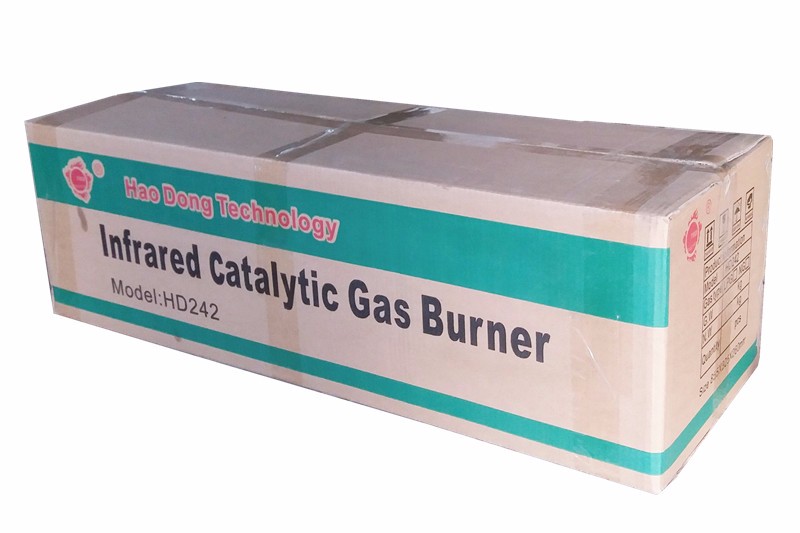

Hot selling HD242 Infrared catalyst Industrial Gas burner pakage

Selling Units: Single Item

Carton Size : 855x300x260mm

Single gross Weight: 29KG

Package Type: 2 Pieces packaged in one carton

1X20 FT CONTAINER,Iterm HD262 quantities about 718-778pcs

1X40 FT CONTAINER,Iterm HD262 quantities about 1619pcs

If you want use your own package , pls.contact us in advance.

If you are interested in our products, welcome to contact us freely!!

We'll do our best to serve for you!!

Francis

Whatsapp/wechat/Mobile: +86 17815004932

Trade manager: cn1516687446falu

QQ: 525379940

Related Keywords