9.4kw natural gas infrared burner for industrial heating conversion kit

- Min. Order:

- 1 Unit

- Min. Order:

- 1 Unit

- Transportation:

- Ocean

- Port:

- chongqing

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 50000 Piece/Pieces per Month |

|---|---|

| Payment Type: | T/T |

| Transportation: | Ocean |

| Port: | chongqing |

9.4kw infrared burner conversion kit for industrial heating

Specification

| Model | Dimension | N.W | Gas Type | Material | Heat Output | Gas Consumption | ||

| L*W*H(mm) | KG | kw/h | Kcal/hr | NG(m3/h) | LPG(KG/h) | |||

| HD242 | 840*130*175 | 11.7 | NG/LPG | Cast iron,Ceramic plate | 9.4 |

8120 |

0.75 | 0.68 |

This cast iron gas burner fits for:

1.Industrial surface treatment:Liquefied/wet drying oven,spray painting oven,electrostatic powder,coating oven,preheating treatment equipment etc.

2.Food baking:Snack puffed food such as biscuit,bread,cooikes,eggroll,rice cake etc;Dehydration of fruit,grain,vegetable,spice;Roasting for fish,duck,chicken,sausage and other meat.

3.Other industrail heating:such as Rubber/plastic thermal forming craft,paper drying,nonwoven fiber drying,mould preheating,glass anneal process,laundry cloth drying plant etc.

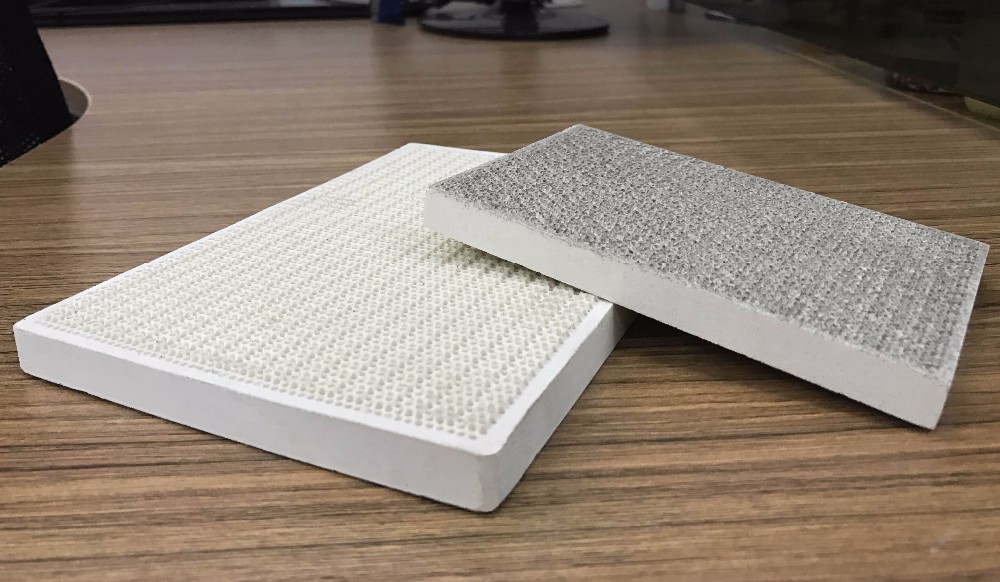

The black catalytic coating on the surface of the honeycomb ceramic plates,that is different with other infrared heaters,also makes advantages as bollowed:

1.High energy transfer rate:above 95%,normal gas burner only 75% to 80%.

2.High efficiency:start to work in 8 seconds.

3.Gas saving:more than 15% to 20%.

4.Infrared Heating directly:Heat direct by radiant infrared ray,no need combustion chamber,blower.

5.Envioronment protecting:Low pollution,less CO,NOx,and less noise.

6.Longer lifetime more than 11000 hours,because it is flameless when it is heating,the catalytic coating have function of anti-carbon combination on the ceramic plates surface,makes the ceramic plates vent free.

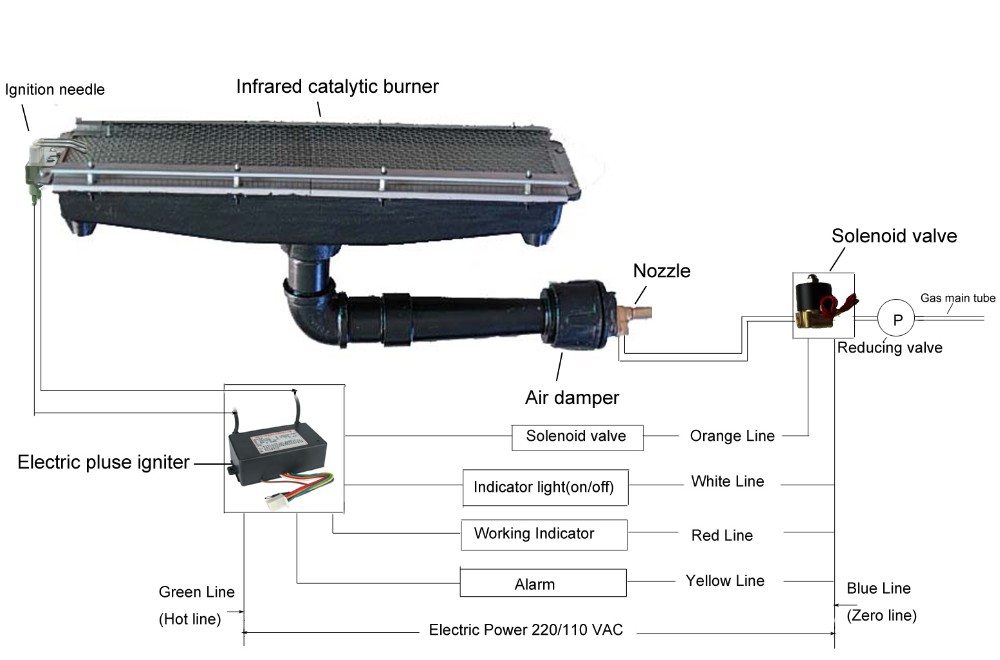

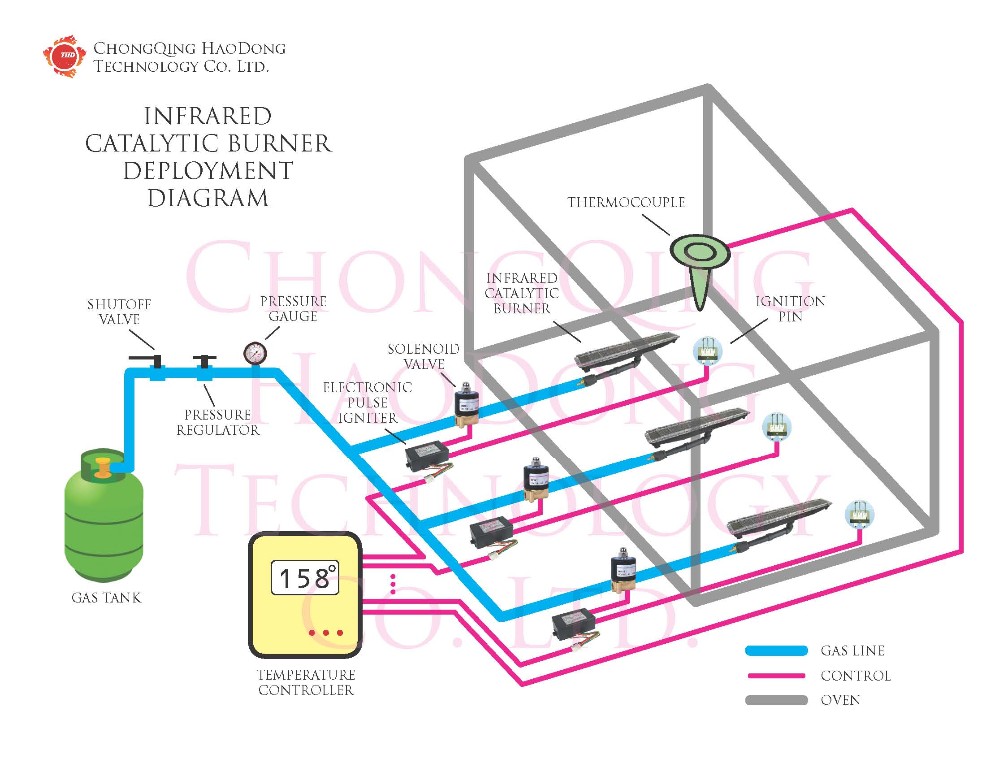

How Does this burner work :

Please send us inquiry for more information.