Industrial infrared ceramic catalytic gas burner kit with ignition pin,electric pulse igniter and solenoid valve

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 50000 Piece/Pieces per Month |

|---|---|

| Payment Type: | L/C,T/T,paypal |

| Transportation: | Ocean |

| Port: | Chongqing |

Industrial infrared ceramic catalytic gas burner kit with ignition pin,electric pulse igniter and solenoid valve

Specification

Haodong manufacture and assemble super efficient infrared radiant gas fired burners suitable for both the OEM and replacement markets. The gas burners can be fitted in a wide range of proprietory process drying, heating and product finishing equipment.

We made infrared burners are designed and constructed to operate on all families of gases and will operate at all gas pressures. They are therefore suitable whatever the gas pressure and in whichever position you wish to fire the burner. - We guarantee it will work!

Flameless when they are working

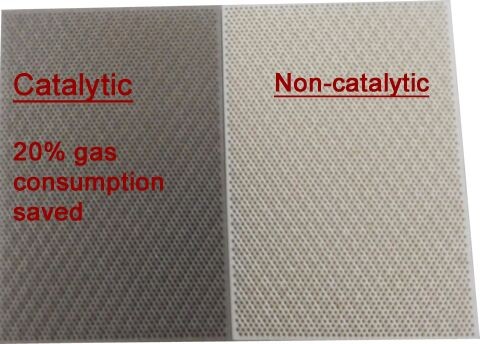

The black catalyst coating on the Cordierite honeycomb plates,makes the gas saving more than 20%,longer lifetime,less carbon monoxide,NOx and noise,also vent free when they were used for many times.

Our infrared burners are used for a wide range of industrial processing including

- Catering equipment - grills, rotisseries, frying ranges, griddles, kebab machines, naan/pitta bread ovens, bainsmarie steamers and boiling units.

- Drying - animal foods, cereal and vegetable crops

- Curing - dry powder and wet paint coating applications, including stove enamelling and vitreous enamel

- Plastic shrink wrapping

- Heat walls - for textile, carpet and paper drying

- Heat treatment ovens

- Forced draught installations - fabrication, welding, pre-heating

- Construction and building industries - concrete and plaster drying, site heating

- Foundry mould and core dring

- Die heating

- Ceramic holloware and flatware - prior/post glazing

- Glass forming

- Metal billet heating

- Destruction of memory in plastics

Please send us inquiry for more information.

Miss Nancy He

Mobile,What's app, Wechat: 008613609400780

Related Keywords