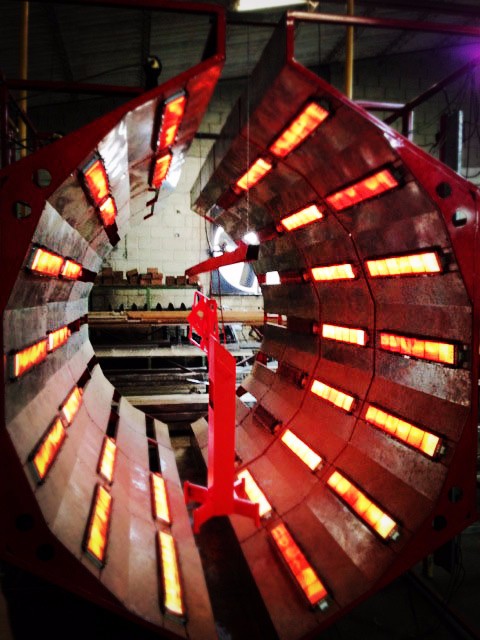

High quality infrared industrial powder coating oven heating part gas burner

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Chongqing, China

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000 Unit/Units per Year |

|---|---|

| Payment Type: | L/C,T/T,paypal, trade assurance |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Chongqing, China |

Established in 2005,our company is a manufacturer ,specialized in the research,development and production of poultry brooder , patio burner,indoor and outside burner ,Industrial infrared lpg heaters.Applications include ovens, furnaces, kilns, fryers and air heaters,powder coating, food baking and Industrial surface treatment .we are located in chongqing with convenient transportation access.

There are three ways to transfer heat, Radiation, Convection, Conduction and their thermal efficiency decrease in turn. Most Equipment is mainly by convection to heat air first and then, the heated air transfer to object. Heat loss is big.

But, differently, infrared gas burner heat object directly by radiation and transfer rate will be much higher, saving about 20% energy.

Infrared catalyst ceramic natural gas catalogue | ||||||||||||||

MODEL | Dimension | Weight | Gas Type | Heat Output | Consumption | |||||||||

mm | kg | KW/h | Kcal/hr | NG(m3/h) | LPG(kg/h) | |||||||||

HD61 | 423*80*94 | 3.8 | NG/LPG | 2.4 | 2030 | 0.18 | 0.18 | |||||||

HD82 | 219*164*108 | 4.8 | NG/LPG | 3.1 | 2700 | 0.24 | 0.24 | |||||||

HD101 | 690*80*115 | 6.9 | NG/LPG | 3.9 | 3380 | 0.3 | 0.29 | |||||||

HD162 | 570*130*175 | 8 | NG/LPG | 6.3 | 5400 | 0.49 | 0.47 | |||||||

HD410 | 410*175*220 | 8 | NG/LPG | 6.3 | 5400 | 0.49 | 0.47 | |||||||

HD242 | 840*130*175 | 11.7 | NG/LPG | 9.4 | 8120 | 0.75 | 0.71 | |||||||

HD600 | 600*175*220 | 11.7 | NG/LPG | 9.4 | 8120 | 0.75 | 0.71 | |||||||

HD262 | 930*130*175 | 13 | NG/LPG | 10.9 | 9360 | 0.8 | 0.82 | |||||||

Advantages

1. Widely used in low pressure (below 6 Kpa)

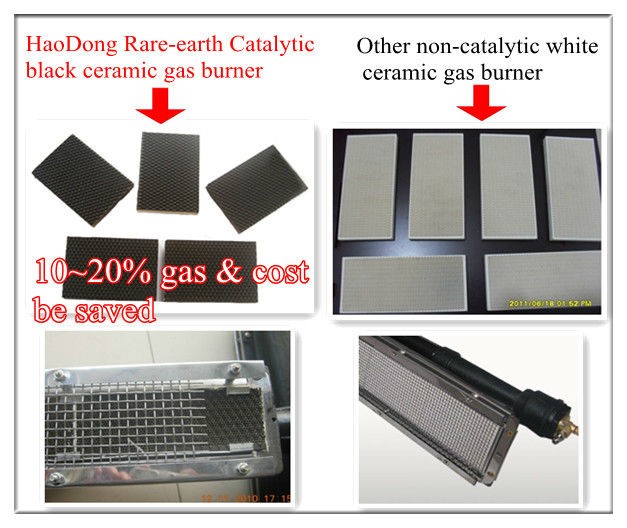

2. Adopting advanced technology of rare-earth catalyst on ceramic plate, about 10%~20% gas consumption

will be saved.

3. Low gas consumption.

4. Even heating,

5. Much cheaper than metal fiber burner

6. Single product has separate control system, it will not influence work of each other

7. Flameless combustion, also suitable for powder products baking process

Energy saving:conversion rate:≥90%

Environmental protection:CO≤80ppm;NOx≤10ppm;CHx≤50ppm

Taking full usage of heat:95% of energy released in the form of infrared ray ;heating the objects directly

Long life:≥11000hr

Easily installed

Application scope

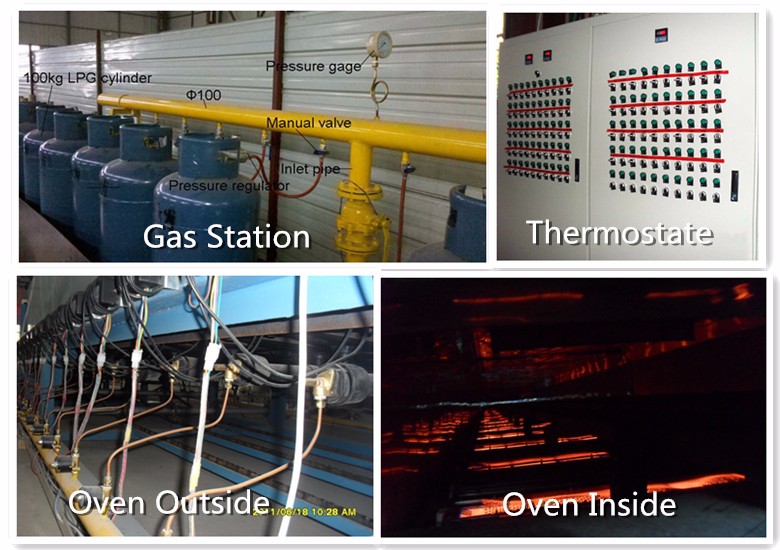

1.Indaustrial Surface Treatment:Liquefield/wet drying oven,spary painting oven, electrostatic powder coating oven,preheating treatment equipment etc.

2.Food Baking:Snack puffed food such as biscuit,bread,cookies,egg roll,rice cake etc.;Dehydration of fruit,grain,vegetable,spice;Roasting for fish,duck,chicken,sausage and other meat.

3.Other Industrial Heating: Rubber/plastic thermal forming craft,paper drying,nonwoven fiber drying,mould preheating,glass anneal process,laundry cloth drying plant etc.

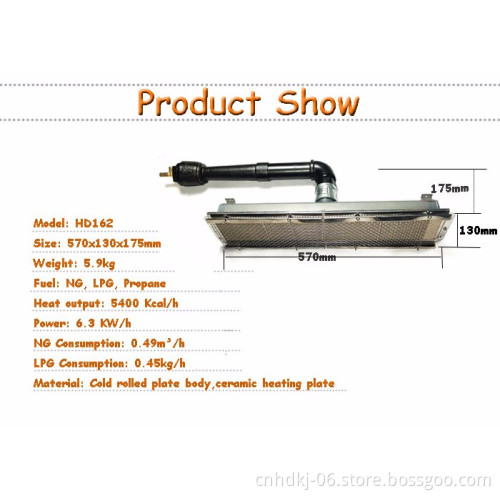

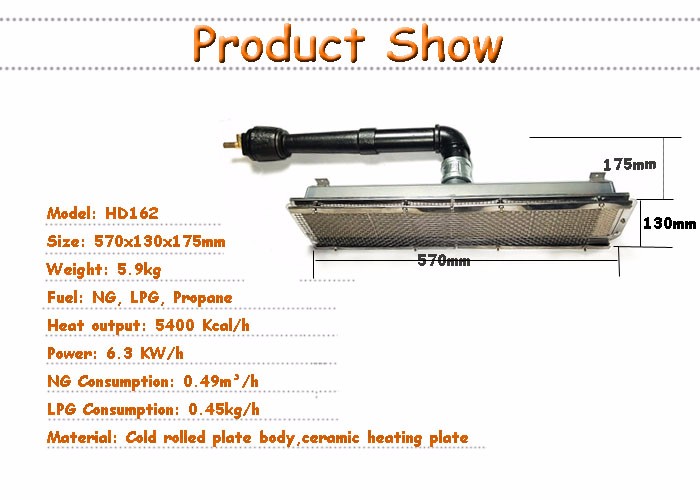

Gas infrared catalytic heaters HD162

Selling Units: Single Item

Carton Size :610x250x290mm

Single gross Weight: 20.1KG

Package Type: 2 Pieces packaged in one carton

Related Keywords