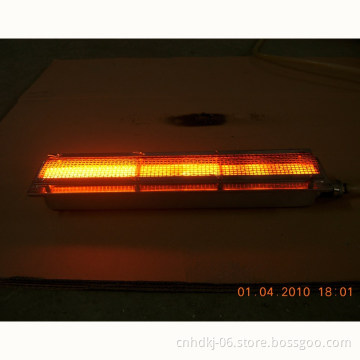

Using infrared gas burners HD262 to preheat oven 350 degrees

- Min. Order:

- 50 Piece/Pieces

- Min. Order:

- 50 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 60000 Piece/Pieces per Month |

|---|---|

| Payment Type: | T/T |

| Transportation: | Ocean |

| Port: | Chongqing |

Using infrared gas burners HD262 to preheat oven 350 degrees

Infrared gas burners specification:

| Model | Dimension | N.W | Gas type | Material | Heat Output | Gas Consumption | ||

| L*W*H(mm) | kg | Kw/h | Kcal/h | NG(m3/h) | LPG(kg/h) | |||

| HD262 | 930*130*175 | 13 | NG/LPG | Cast iron cover,Ceramic plate heated | 10.9 | 9360 | 0.8 | 0.74 |

Ceramic burning surface can reach 850 Degrees Celsius

Features and Benefits:

Input fuel is converted to 75% infrared,25% convective energy.

Catalytic combustion makes more 15% to 20% gas saving.

Stainless steel spacer (slit orifice) to deliver an even air/gas mixture.

High temperature, corrosion resistant alloy side plates.

Machined cast iron body.

Modular burner sections with carbon steel orifice union connectors.

Replaceable ceramic refractory emitters.

Radiant heat is distributed uniformly.

High velocity radiant heat diffuses surfaces boundary layers on product process.

No ported holes to clog.

Longer wear resistance no dark areas on refractories.

Less warping, increased burner longevity.

Structural integrity in continuously operating ovens.

Quick and easy replacement of burner sections with uniform firing rate across entire burner length.

Lower stress design and cost effective maintenance.

This infrared gas burner fits for:

Drying oven - animal foods, cereal and vegetable crops.

Curing oven - dry powder and wet paint coating applications, including stove enamelling and vitreous enamel

Plastic shrink wrapping.

Heat walls - for textile, carpet and paper drying.

Heat treatment ovens.

Forced draught installations - fabrication,pre-heating.

Foundry mould and core dring.

Die heating.

Ceramic holloware and flatware - prior/post glazing.

Metal billet heating.

Metal annealing.

Rubber/plastic forming,glass anneal process,nonwoven fiber drying.

For more information about our catalytic infrared gas burners,please send us inquiry or contact Daniel An with:

Skype:anzanly

Whatsapp:0086 18423123054

Wechat:18423123054