Infrared gas heater spare parts for powder coating oven HD262

-

$78.0010-99 Piece/Pieces

-

$75.00≥100 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowInfrared gas heater spare parts for powder coating oven details

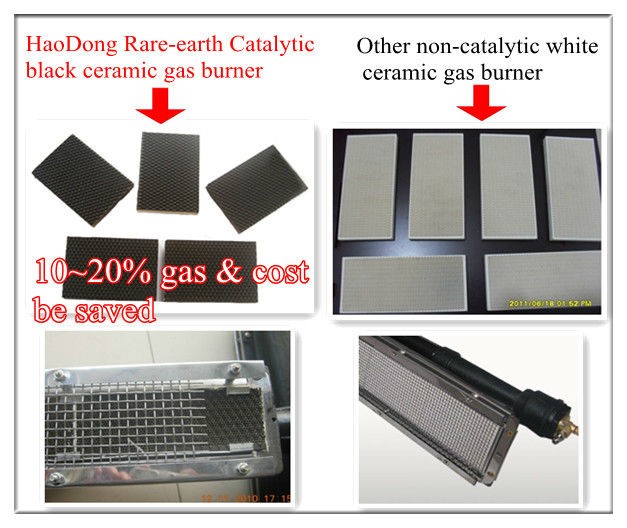

There are three ways to transfer heat, Radiation, Convection, Conduction and their thermal efficiency decrease in turn. Most Equipment is mainly by convection to heat air first and then, the heated air transfer to object. Heat loss is big. But, differently, infrared gas burner heat object directly by radiation and transfer rate will be much higher, usually it can save 10~20% gas energy and cost.

Model | Dimension | Weight | Gas type | Heat Output | Consumption | ||||

mm | kg | KW/h | Kcal/h | NG (m3/h) | LPG (kg/h) | ||||

HD162 | 570*130*175 | 8 | LGP/NG | 6.3 | 5400 | 0.49 | 0.45 | ||

HD242 | 840*130*175 | 11.7 | LGP/NG | 9.4 | 8120 | 0.75 | 0.68 | ||

HD262 | 930*130*175 | 13 | LGP/NG | 10.9 | 9360 | 0.8 | 0.74 | ||

Infrared gas heater spare parts for powder coating oven materials:

1. Shell: Cast Iron

2. Radiant part: cordierite honeycomb plates with catalyst coated

3. Nozzle: brass

4. Up cover: stamped stainless iron

cheap Infrared industrial lpg gas burners

cheap Infrared industrial lpg gas burners

20% gas consumption saved, less gas Emission

The gas burner applied catalyst technology on ceramic plates, which make burning fully and save 20% gas than normal gas burner.

Besides, it make less gas emission.

We are the Only Chinese company use catalytic on infrared gas burner.

Contact information

If any need, welcome to contact us freely!!

Ms. Kathy Tang

Related Keywords