Double-stage Transformer Oil Filtration Machine

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean

- Port:

- CHONGQING

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000 per month |

| Supply Ability: | 1000 Per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | ISO9001 |

| Transportation: | Ocean |

| Port: | CHONGQING |

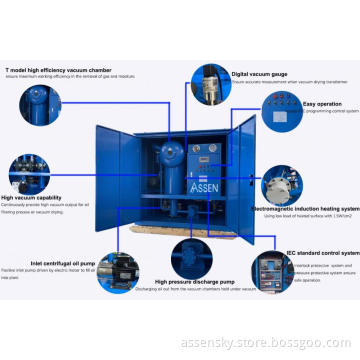

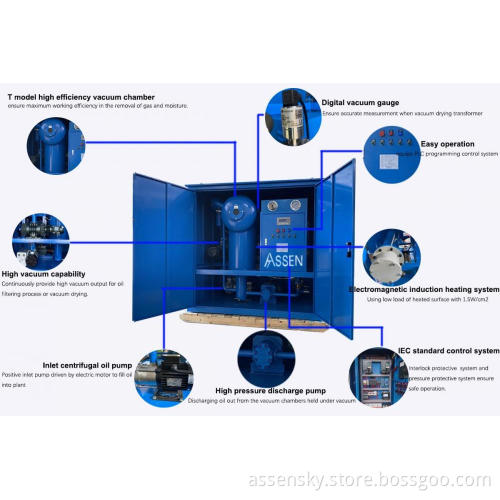

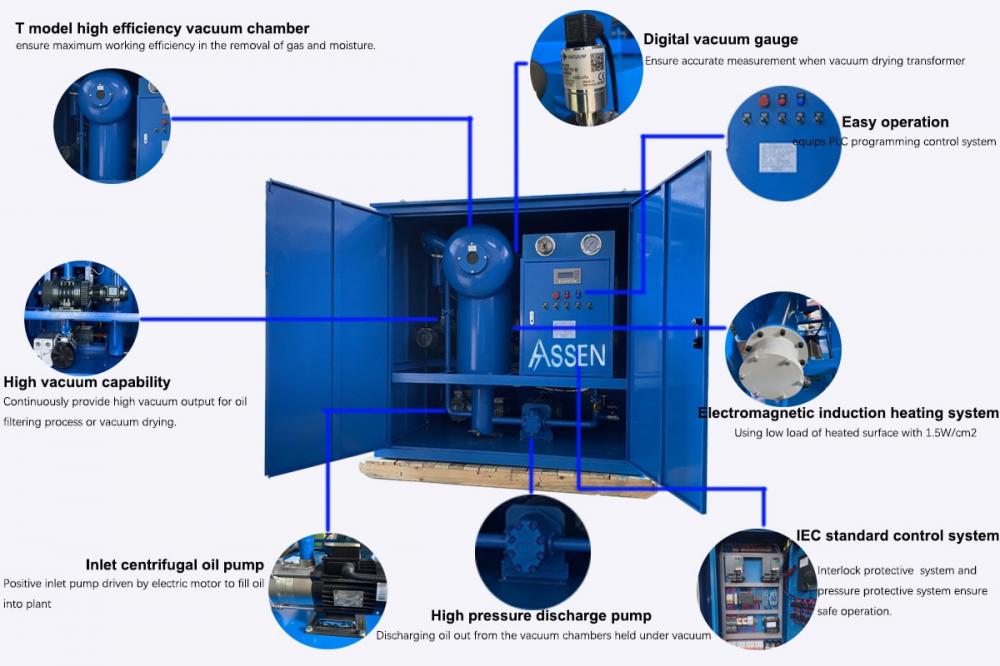

Application

Assen ZYD Double Stage Transformer Oil Purifier is the solution to your on site transformer oil maintenance, the filtering of transformers is one of the least expensive, best known ways of extending the life of the unit.

When it comes to transformer oil processing ASSEN have the equipment, experience and skilled personnel to perform oil processing on your power transformers, safely and efficiently. From vacuum filling to hot oil cleaning we can handle the project

The plant can be used to process oil for the initial fill, after maintenance refill or as a process to keep all your oil filled equipment in optimum operating condition. It can remove the water content, gas, and other impurities from the oil fast and effectively, and after treatment, the oil can be used as new oil.

Features

1. Vacuum pump and booster pump to ensure effectively and fast removing the impurities

2. Three-stage filter system

3. Z-shape Heater to make the heating uniformity

4. Installing oil-level floating ball and double-infrared liquid level automatic controller to control the oil level

5. Foam sensor to avoid oil leaking

6. Temperature Controller to protect the machine

7. Suitable oil filtration machine for high voltage transformer

8. Large filtration area, high capacity of holding impurities

9. Two vacuum separator to increase separating size and time and ensure the drying degree and improve dielectric strength which is higher than 75 KV.

10. Doing online oil purification of substations over 110 KV.

11. Independent function of vacuum oil filling and drying.

12. Duplex stereo flash evaporation technology

13. Equipped with pressure protective system and interlocked protective system to connect oil pump, heater and liquid level controller.

14. Saving energy, time, human consumption and oil cost

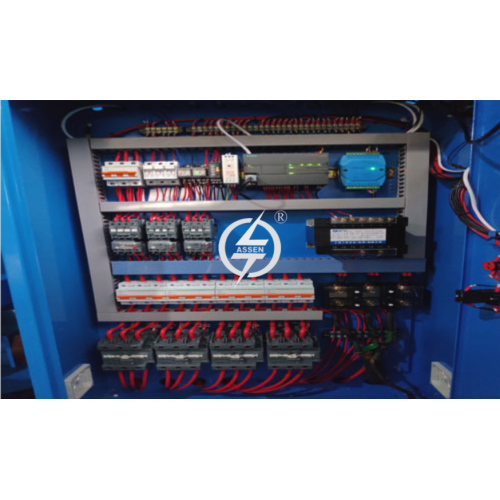

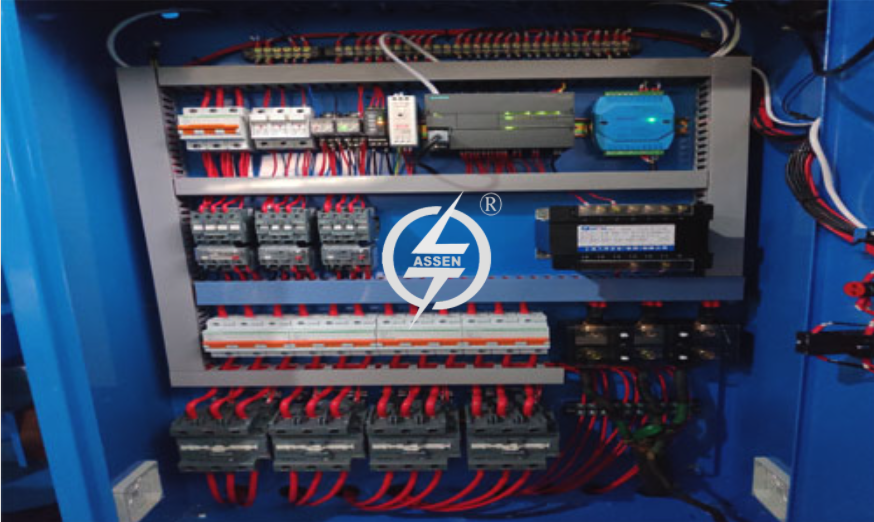

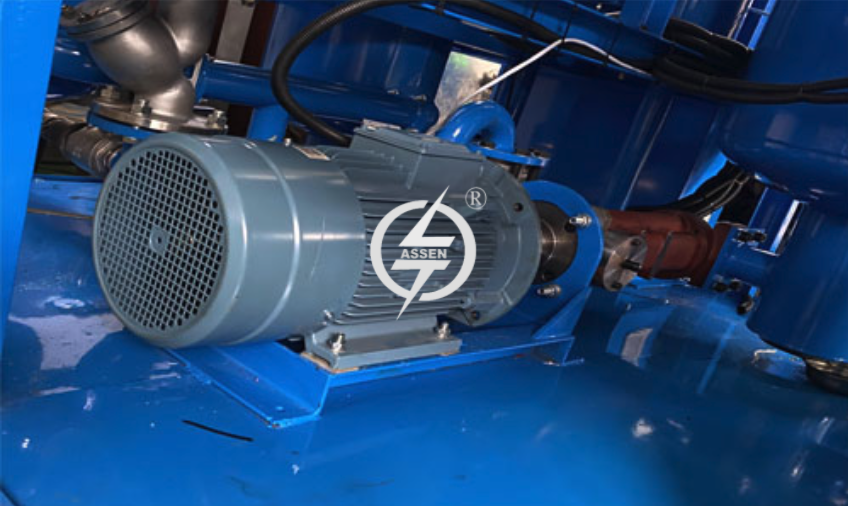

Main parts of ZYD

Technical Data

|

Parameters |

Unit |

ZYD-30 |

ZYD-50 |

ZYD-100 |

ZYD-150 |

ZYD-200 |

ZYD-250 |

ZYD-300 |

|

|

Flow |

L/min |

30 |

50 |

100 |

150 |

200 |

250 |

300 |

|

|

Working vacuum |

MPa |

0.08 ~ 0.099 |

|||||||

|

Working Pressure |

MPa |

≤0.3 |

|||||||

|

Temperature Range |

℃ |

20 ~ 80 |

|||||||

|

Power |

|

Three Phase 50HZ380V(as per the customer's requirements) |

|||||||

|

Working Noise |

dB(A) |

75 |

75 |

75 |

80 |

80 |

80 |

80 |

|

|

Heating Power |

kW |

30 |

30 |

45 |

60 |

75 |

90 |

120 |

|

|

Total Power |

kW |

35.5 |

37.5 |

52.5 |

71.4 |

86.5 |

102.5 |

135 |

|

|

Inlet/Outlet |

mm |

φ25 |

φ32 |

φ42 |

φ50 |

φ50 |

φ60 |

φ60 |

|

|

Weight |

kg |

600 |

800 |

1050 |

1400 |

1800 |

2000 |

2200 |

|

|

Overall |

Length |

mm |

1050 |

1100 |

1200 |

1450 |

1600 |

1800 |

1900 |

|

Width |

mm |

750 |

800 |

950 |

950 |

1100 |

1200 |

1200 |

|

|

Height |

mm |

1350 |

1400 |

1500 |

1650 |

1800 |

1900 |

1900 |

|

Delivery

Related Keywords