Assen ZYD-I high vacuum transformer oil regeneration system

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

- Port:

- Chongqing, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100 per week |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Air |

| Port: | Chongqing,Shanghai |

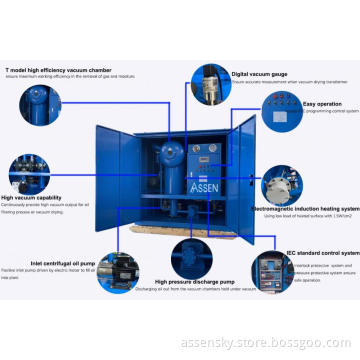

Features

1.Double-stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value ≤ 5Pa

2.Two vacuum separating chambers, efficient oil film sprayer, increasing separating size and separating time to ensure the dry-level and dielectric strength improving greatly.

3.Double-horizontal film evaporation technology, combined with unique and advanced dewatering, degassing components, can rapidly and effectively separate water, gas from oil.

4.Multi-stage precision filtration system, mesh filtration combined with molecular adsorption technologies.

5.Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

6.Double-infrared liquid level sensor, pressure protective system to ensure machine operation easy and safely.

7.Adopt interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

8.Functions of live line work onsite, vacuum drying and vacuum oiling.

Application:

Dissolved gasses in transformer oil can cause arcing, corona discharges, and overheating–reducing the electrical efficiency and lifetime of the transformer. Likewise, water contamination at levels as low as 30 ppm (parts per million) can adversely affect the insulating strength of the oil. With ever-increasing standards for energy efficiency of power distribution transformers, the need to effectively degas will become even more important in the future. particles contamination will also affect the function of insulating oil. So we need to clean used transformer oil.

|

Parameters |

Unit |

ZYD-I-30 |

ZYD-I-50 |

ZYD-I-100 |

ZYD-I-150 |

ZYD-I-200 |

ZYD-I-250 |

ZYD-I-300 |

||

|

Flow |

L/min |

30 |

50 |

100 |

150 |

200 |

250 |

300 |

||

|

Working vacuum |

MPa |

0.08 ~ 0.099 |

||||||||

|

Working Pressure |

MPa |

≤0.4 |

||||||||

|

Temperature Range |

℃ |

20 ~ 80 |

||||||||

|

Power |

|

Three Phase 50HZ380V(as per the customer’s requirements) |

||||||||

|

Working Noise |

dB(A) |

75 |

75 |

75 |

80 |

80 |

80 |

80 |

||

|

Heating Power |

kW |

30 |

40 |

60 |

90 |

120 |

150 |

180 |

||

|

Total Power |

kW |

35.5 |

41.5 |

62.5 |

95.5 |

128.5 |

159.5 |

192 |

||

|

Inlet/Outlet |

mm |

φ25 |

φ32 |

φ42 |

φ50 |

φ50 |

φ60 |

φ60 |

||

|

Weight |

kg |

400 |

550 |

800 |

950 |

1100 |

1300 |

1600 |

||

|

Overall |

Length |

mm |

1350 |

1480 |

1850 |

1950 |

2100 |

2150 |

2250 |

|

|

Width |

mm |

1320 |

1450 |

1810 |

1900 |

2000 |

2100 |

2200 |

||

|

Height |

mm |

1350 |

1460 |

1860 |

1930 |

2150 |

2200 |

2300 |

||

Keywords

Oil purification, transformer oil treatment, transformer oil filtration, transformer oil regeneration, insulating oil purifier machine, delectric oil treatment machine

Related Keywords