PLC Control System Transformer Oil Dehydration Equipment

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Chongqing, Shanghai, Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 per week |

| Supply Ability: | 100 per week |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001 & CE |

| Transportation: | Ocean |

| Port: | Chongqing,Shanghai,Tianjin |

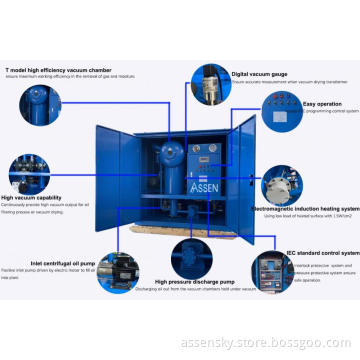

PLC Control System Full Closed Door Type Vacuum Transformer Oil Dehydration Equipment, Insulating Oil Filtration

Application

PLC Control System Full Closed Door Type Vacuum Transformer Oil Dehydration Equipment is widely used in electric power, petroleum, chemical industry and railway etc for outdoor use insulating oil filtration.It is also used for hot oil circulation drying and oil purification when various large transformer equipment installation and maintenance. Purifying insulating oil in 110KV-330KV transformer, also suitable for high grade new oil, imported oil deep purifying. It adopts PLC Control System, an intelligent panel control, 10 inches touch screen operation, and dynamic display to record the operation data during process.

Features

1.A capability of reducing moisture content from 50ppm to 3ppm moisture and 12% gas content to less than 0.1% by volume. 98% of particulate matter will also be removed.

2. Double-Stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value no more than 5Pa

3. Duplex-Stereo film evaporation technology, combined with unique and advanced dewatering, degassing components, can rapidly and effectively separate water, gas from oil.

4. An advanced fully automatic temperature controlling system, liquid-level controlling system, defoaming controlling system, pressure protecting system and excellent configuration can ensure operation of the equipment with high performance

5. Online work, allowing separated operation of manual operators from machine with lamps indicating the condition for operation.

6 It is humanization design with low noise, deep purification and long time free maintenance to save cost from the running process.

Technical Parameters:

|

Parameters |

Unit |

ZYD-M-30 |

ZYD-M-50 |

ZYD-M-100 |

ZYD-M-150 |

ZYD-M-200 |

ZYD-M-250 |

ZYD-M-300 |

|

|

Flow rate |

L/min |

30 |

50 |

100 |

150 |

200 |

250 |

300 |

|

|

Working vacuum |

MPa |

0.08 ~ 0.099 |

|||||||

|

Working Pressure |

MPa |

≤0.3 |

|||||||

|

Temperature Range |

℃ |

20 ~ 80 |

|||||||

|

Power |

Three Phase 50HZ380V(as per the customer’s requirements) |

||||||||

|

Working Noise |

dB(A) |

75 |

75 |

75 |

80 |

80 |

80 |

80 |

|

|

Heating Power |

kW |

30 |

30 |

45 |

60 |

75 |

90 |

120 |

|

|

Total Power |

kW |

35.5 |

37.5 |

52.5 |

71.4 |

86.5 |

102.5 |

135 |

|

|

Inlet/Outlet |

mm |

φ25 |

φ32 |

φ42 |

φ50 |

φ50 |

φ60 |

φ60 |

|

|

Weight |

kg |

600 |

800 |

1050 |

1400 |

1800 |

2000 |

2200 |

|

|

Overall |

Length |

mm |

1050 |

1100 |

1200 |

1450 |

1600 |

1800 |

1900 |

|

Width |

mm |

750 |

800 |

950 |

950 |

1100 |

1200 |

1200 |

|

|

Height |

mm |

1350 |

1400 |

1500 |

1650 |

1800 |

1900 |

1900 |

|

|

Moisture |

PPM |

≤3 |

|

Gas content |

% |

≤0.01 |

|

Impurity size |

μ |

≤1 (no free carbon) |

|

Breakdown voltage |

kV |

≥75 |

|

IFT |

dynes/cm |

≥40 |

|

Acid value |

mgKOH/g |

≤0.03 |

|

Dielectric loss factors |

tgδ(90°C) |

≤0.001 |

Keywords:

transformer oil purifier, oil clean, oil reuse, oil recycle, transformer maintain, transformer service, transformer oil filter, insulating oil, breakdown voltage, water remove, gas remove, impurities in oil, aging oil treatment, transformer oil treatment

Related Keywords