Cummins Engine NTA855-P450 for Dredger

Your message must be between 20 to 2000 characters

Contact Now| Certificate: | ISO9001:14001 |

|---|

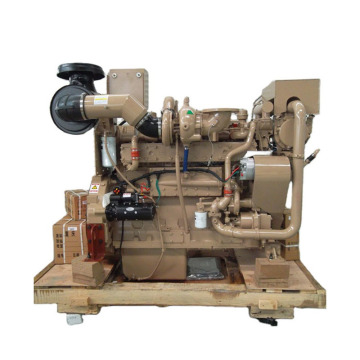

Product Name: Cummins Pump Engine

Engine Model:NTA855-P450

|

Technical Specification |

|||

|

Engine Model |

NTA855-P450 |

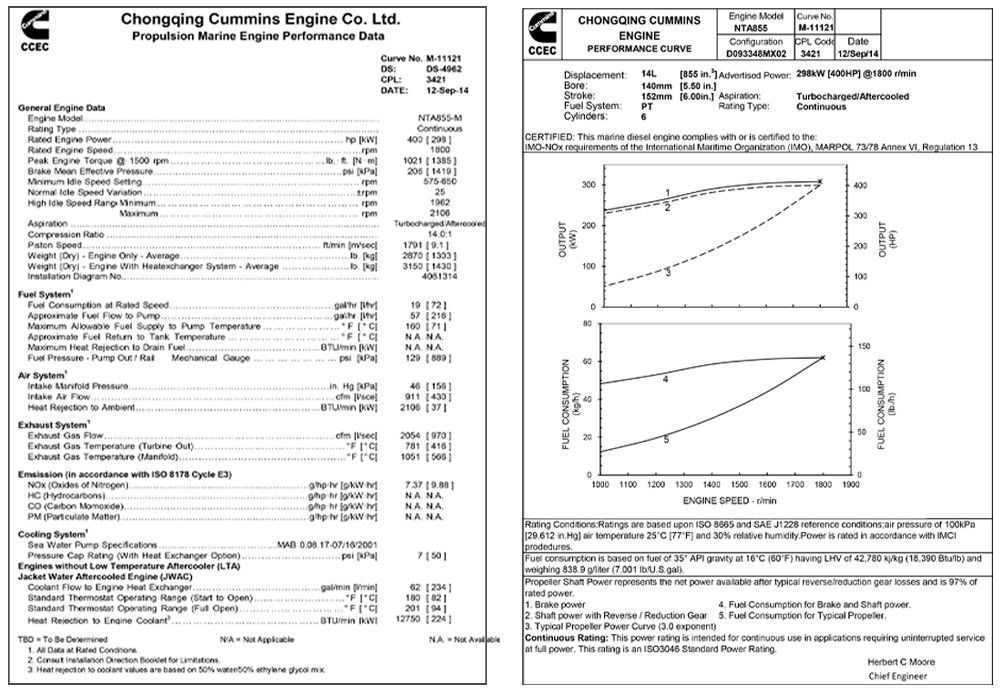

Fuel Consumption |

19gal/hr |

|

Rating Type |

Continuous |

Fuel Flow |

57gal/hr |

|

Rated Power |

450hp / 336kW |

Manifold Pressure |

194kPa |

|

Rated Speed |

1500/1800/2100rpm |

Intake Air Flow |

3597 cfm |

|

Peak Torque |

1385 NHm |

Heat Rejection |

4464 BTU/min/78kW |

|

Cylinders |

6 |

Size-Engine Only |

1900*1150*1900mm |

|

Aspiration |

Turbocharged |

Weight (Dry) |

1400kg |

|

Compression Ratio |

14.0:1 |

Idle Speed Setting |

575-650rpm |

|

Piston Speed |

1791 ft/min |

Idle Speed Variation |

±25rpm |

|

Displacement |

14L |

High Idle Speed Min |

1962rpm |

|

Bore*Stroke |

140*152mm |

High Idle Speed Max |

2106rpm |

|

Fuel System |

PT pump |

Thermostat Operating |

82°C-94°C |

|

Optional Configuration |

According to the type of cooling( Water-cooled, Air-cooled.) Configuration: Radiator,Fan / Heat Exchanger(Keel cooling), Expansion tank, Sea water pump, Control system, Remote control system. |

||

Cummins Features and Benefits

■ Crankshaft and Rod

Robust and fully balanced crankshaft design for a more steadily rotation and higher strength. Steel piston crown with oil gallery and aluminum skirts for better durability and low oil consumption.

■ Fuel System

Cummins unique PT with fixture and Step Timing control for precise fuel injection make the fuel injection pressure above 120Mpa, which leads to an excellent fuel consumption rate and emission performance. Check valve in fuel tube improve reliability.

■ Lubrication System

Dual spin-on filter can separate impurity above 10um effectively. Low pressure(220-310Kpa) and steady temperature(100-120°C)system can reduce auxiliary power wasting of the lubricating oil pump.

■ Cooling System

Great flux water pump and special channel design provide effective cooling. Spin in water filter makes the coolant clean and keeps it in normal acidity.

■ Exhaust System(After-cooled)

Advanced Holset turbocharger and water-air after cooler technology, pulse exhaust manifold reduce exhaust temperature, provide excellence fuel consumption and emission performance.

Related Keywords