Brass Rivet CNC Milling Parts CNC Machining Prototyping

$1.00 - $10.00/Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shganghai, guangzhou, chongqing

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000/month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,CIP,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shganghai,guangzhou,chongqing |

Product Description

Product Description

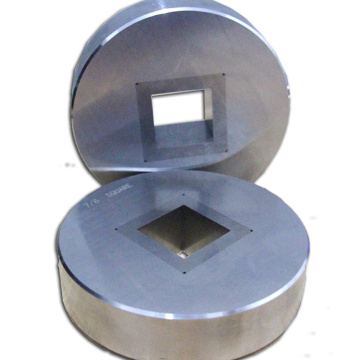

CNC Processing

1. Vertical machining center: A machining center whose spindle is in a vertical state in space is called a vertical machining center. The vertical machining center machine should be suitable for processing complex parts such as plates, discs, molds and small shells. The vertical machining center can complete the processes of milling, boring, drilling, tapping and thread cutting. Vertical machining centers are rarely three-axis and two-linkage, and generally can achieve three-axis and three-linkage. Some can carry out five-axis, six-axis control. Compared with the corresponding horizontal machining center, the structure is simple, the floor space is small, and it is more affordable.

More product:

2. Horizontal machining center: A machining center whose spindle is horizontal in space is called a horizontal machining center. Horizontal machining centers are suitable for mass production of products with complex shapes and high precision requirements, especially the processing of boxes and complex structural parts. It is used extensively in the automotive, aerospace, marine and power generation industries for the precise and efficient machining of complex parts. Compared with the vertical machining center, the horizontal machining center has a complex structure, a large area, and a high cost. Moreover, the horizontal machining center is inconvenient to observe during machining, and it is inconvenient to clamp and measure parts, but it is not convenient for chip removal during machining. Easy, good for processing.

3. Compound machining center: The spindle of the machining center can be converted horizontally and vertically, which is called a vertical and horizontal machining center, and also becomes a compound machining center. The compound machining center completes a variety of machining procedures by clamping the workpiece at one time, which shortens the machining time and improves the machining accuracy. CNC turning and milling compound machining center is the main model of compound machining center. It usually realizes machining processes such as plane milling, drilling, tapping, and slot milling on CNC lathes. It has compound functions such as turning, milling, and boring. to complete the entire process.

CNC Machining Parts

Milling

Turning

Titanium Parts

Aluminum Parts

Stainless Steel Parts

Brass

Surface Coating

Fastener(Non-s)

Apply to

Optical semiconductor equipment parts, medical parts, aviation parts, telecommunication parts, industrial equipment parts, rail transit parts, energy industry parts, special industry parts.

Processing capability of various materials: aluminum alloy, stainless steel, all kinds of steel, pure titanium, titanium alloy, cast iron, copper, molybdenum, nickel alloy, nickel zinc ferrite, ceramics, magnesium alloy, etc.

Experienced in a variety of surface treatments, corrosion processing, anodizing, passivation treatment, coating process, heat treatment, laser marking, mechanical case-solving light, spray painting, sandblasting, etc.

Related Keywords

Related Keywords