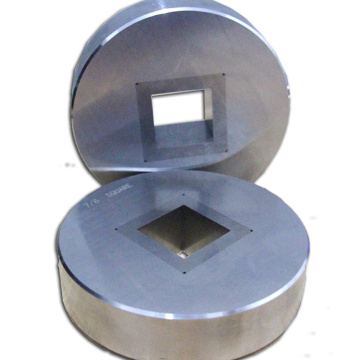

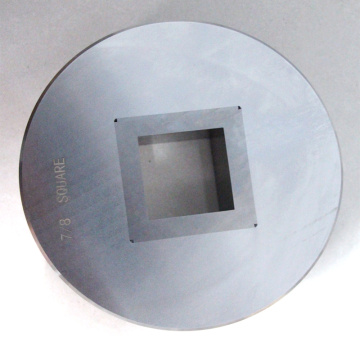

Cold Heading Screw Mold Die

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Carton, Wooden Box; Export Standard Package, Or As Client's Requirement of Trimming Dies

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 5000 Piece/Pieces per Month |

|---|---|

| Payment Type: | L/C,D/P,D/A,T/T,MoneyGram,credit card |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Carton,Wooden Box; Export Standard Package,Or As Client's Requirement of Trimming Dies |

Cold Heading Screw Mold Die Tungsten Carbide Punches And Dies With Grinding Surface

1. Select the tungsten steel materials and specifications size to make the screws or nuts mold correctly.

2.According to the difference of the forming difficulty,size,length of screws and nuts,rational design of the mold structure,multi-station and nut mold should be allocated on a reasonable basis the upsetting deformation and the number of molding.

3.The mold fine craftsmanship,accurate size,bore diameter to match the finish mirror requirements.

4.Interference voltage distribution margin,select the appropriate alloy taper size.

5.Shell steel sleeve must be rigid and good heated,and the hardness range should be between 42°c-48 °c after the vacuum heat treatment.

6.Keep the mold bore and the wire surface cleaning and smoothing, cold drawn wire must be nailed after ball annealing treatment.

7.We use diamond grinding wheel to mill the cycle and the end of tungsten.

8.The technicians adjusting the master must have good technical level.

Advantages and application of tungsten steel punch:

Tungsten steel (cemented carbide) has a series of excellent properties, such as high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance, etc., especially its high hardness and wear resistance, which are basically unchanged even at 500 ℃, and still have high hardness at 1000 ℃

Tungsten steel, mainly composed of tungsten carbide and cobalt, accounts for 99% of all components and 1% of other metals, so it is called tungsten steel, also known as cemented carbide, which is considered as the teeth of modern industry. What's the advantage of using tungsten steel punch compared with others?

we specailize in the development ,production and sales of various tungsten carbide dies.

we have CNC lathes, CNC machining centers, CNC cylindrical grinding machine, CNC EDM machine, CNC cutting machine, Milling andam drlling machine,etc.we also have various types testing equipment, such as Rockwell Hardness tester, projecor,3D Image Measuring Instrument, etc. we use high-quality tungsten carbide material and professional vacuum heat treatment .we design manufacturing and supply high-quality precision molds for customers who engaged in cold heading and hot upsetting industries. about our molds, the RSD can be controlled whthin 0.005mm, concentricity can be controlled whithin 0.01mm. strict accordance with ISO9001:2015 qualityy mangement system requirments of the operation, casn ensure provide timely and high-quality service for our customers

Usually, we choose the following ways to transport our molds, if you have other options or requirements, we are also welcomed.

For more further information please Click "Send" Now!!

It's our pleasure to provide you good quality products with good price and service always.

Related Keywords