Tungsten Segmented Hex Dies Composed Of Mould Steel

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Express

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 30000 Piece/Pieces per Month |

|---|---|

| Payment Type: | Western Union,T/T |

| Transportation: | Express |

| Port: | Chongqing |

Tungsten Segmented Hex Dies Composed Of Mould Steel (Skd11/Skd61)

Hole size: H6~H50 (mm)

Material: Tungsten carbide(VA80, ST7, G6, YG20, etc) and Die Steel(H13)

Provide design services

Segmented dies can be supplied as either inserts or complete die assemblies in tungsten carbide or special steels. The advantages of extended tool life offered by interchangeable segmented inserts are now widely recognised. All tools are certified prior to despatch to our customers.

Being a highly effective and fast-moving firm, Henghui is actively engrossed in offering an exclusive assortment of Hex Segmental Dies. The offered products are highly acclaimed across the globe for their optimum quality and easy installation. Manufactured under innovative professionals with advanced techniques, these dies are used in various in various industries for making varied types of fasteners. Apart from this, the products offered by us are available in diverse sizes as per client's demands.

we specailize in the development ,production and sales of various tungsten carbide dies.

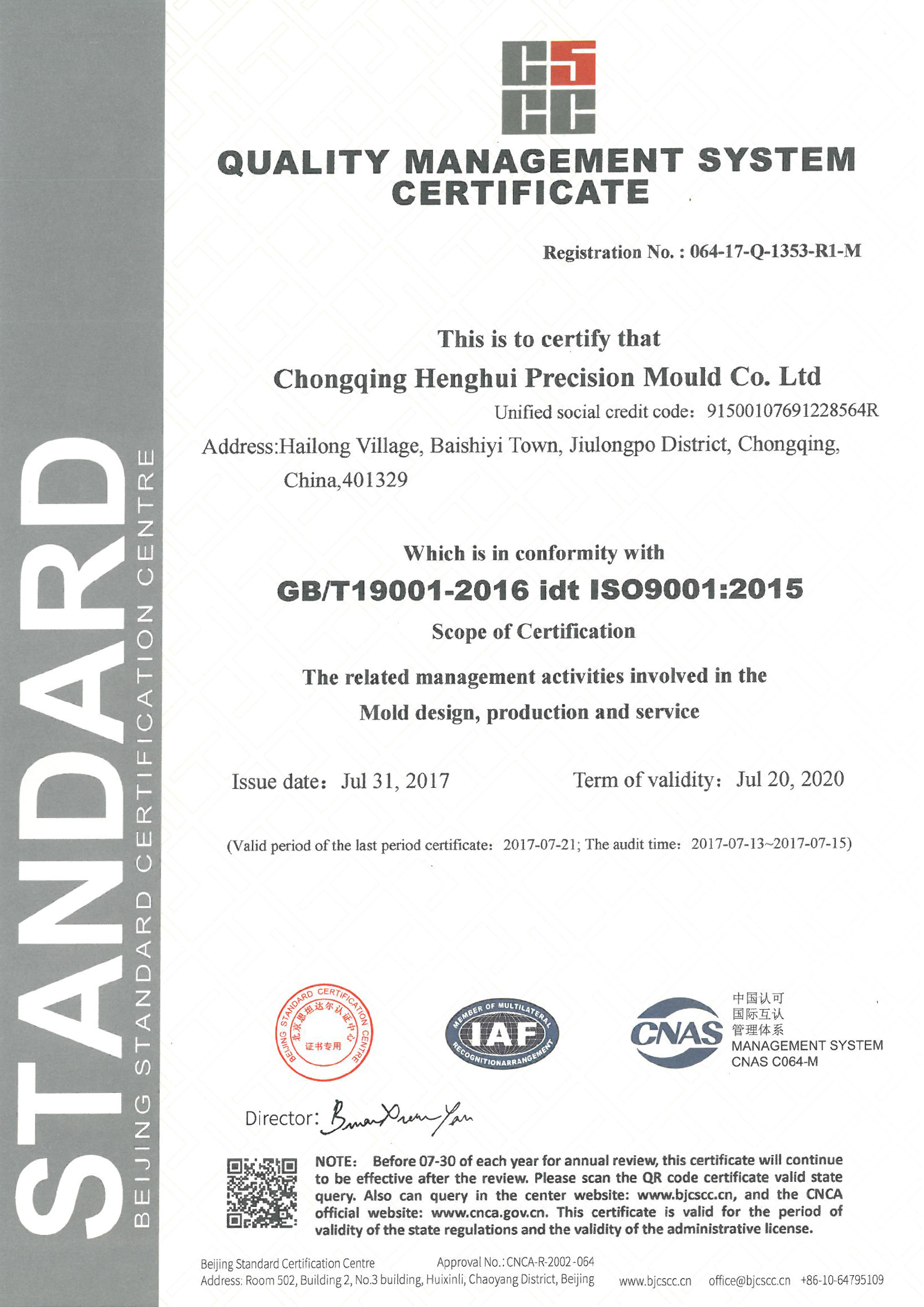

we have CNC lathes, CNC machining centers, CNC cylindrical grinding machine, CNC EDM machine, CNC cutting machine, Milling andam drlling machine,etc.we also have various types testing equipment, such as Rockwell Hardness tester, projecor,3D Image Measuring Instrument, etc. we use high-quality tungsten carbide material and professional vacuum heat treatment .we design manufacturing and supply high-quality precision molds for customers who engaged in cold heading and hot upsetting industries. about our molds, the RSD can be controlled whthin 0.005mm, concentricity can be controlled whithin 0.01mm. strict accordance with ISO9001:2015 qualityy mangement system requirments of the operation, casn ensure provide timely and high-quality service for our customers

|

Carbide die:Straight hole dies/Extrusion dies /Nut die /Segmented Hex Dies /Cutter&knife |

||||

|

Tube drawing die |

Cutting&Trimming dies |

thread rolling die |

2nd punch |

punch pin HSS |

classification by process nature:

(1) the blanking die separates the material along the closed or open contour line. Such as blanking die, punching die, cutting die, cutting die, cutting die, cutting die and so on.

(2) the bending die makes the blank or other blank produce bending deformation along the straight line (bending curve), so as to obtain a certain angle and shape of the workpiece mold.

(3) the drawing die is a die which can make blank into open hollow part or make hollow part change shape and size further.

(4) the forming die is a kind of die which can directly copy the blank or semi-finished workpiece according to the shape of the convex and concave die, while the material itself only produces local plastic deformation. Such as bulging die, necking die, expanding die, rolling forming die, flanging die, shaping die, etc.

Pre-sale

First confirm the types and quatity with customers

Patient, serious, carefully

Arrange to produce and care for the leadtime

Before delivery , confirm the items carefully

After sales

Arrange to delivery as soon as possible

Confirm the items if arrived at customers' hands

Get feedback from customers and try to do best

Usually, we choose the following ways to transport our molds, if you have other options or requirements, we are also welcomed.

We also have good after-sales service system to provide quality aftar-sales service for customers.

Related Keywords