Forging Mould Tungsten Carbide Wire Drawing Dies

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Shenzhen Shanghai Ningbo Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 2000 Set/Sets per Month Punching Die |

|---|---|

| Payment Type: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Cash,Credit card |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Shenzhen Shanghai Ningbo Chongqing |

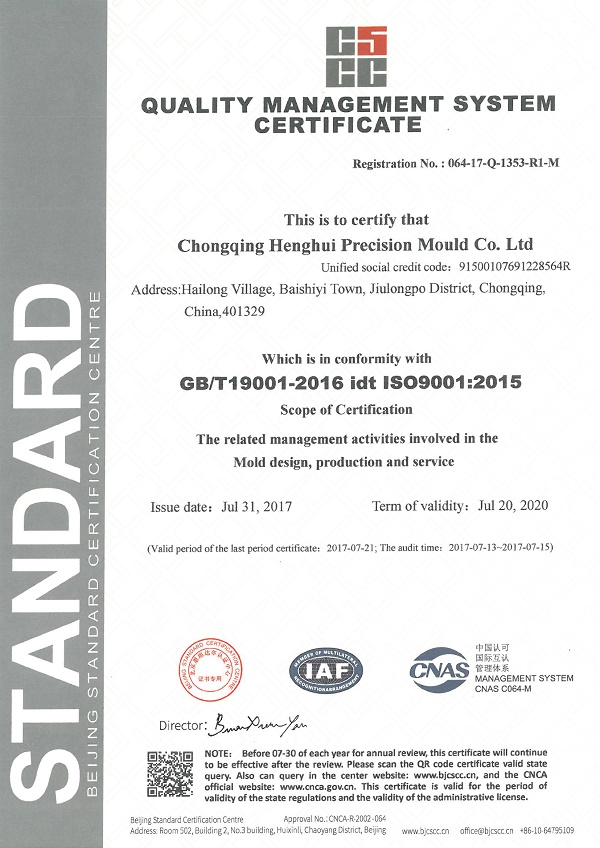

Precision ISO 9001 Forging Mould Tungsten Carbide Wire Drawing Dies

Henghui's Tungsten Carbide Dies are designed with high precision in order to meet the international quality standards. We offered dies are known for their robust designs, professional processing and longer service life.Tungsten Carbide Dies can be used in the production of fasteners and can also be applied to other industries.Apart from this, the offered tungsten carbide dies are available in various sizes and dimensions as per the varied needs of the clients.

Why choose us?

1.Efficiency &Profession

Time is gold for two trading parties. We have a professional line and staff who offer you best price and good quality in a short time .Any inquirs will be replied with 24 hours.

2.Convinient & Safety

We are a member of Alibaba Trade Assurance which is a new service provided by Alibaba ,

100%product quality protection

100%on-time shipment protection

100%payment protection for your covered amount.

"Customer first, quality first, technology first, dedicated service" is our consistent operating principles.Warmly welcome to negotiate business with us.

Tungsten Carbide Die has been a substitute of steel mould which is used to stretching steel and

non-ferrous metal, with the property of high wear resistance, good polishing performance, low

friction coefficient, etc.

We can process all kind of high quality Mold Parts Punches accoring to client's requirement. Our is equipped with new modern high precision CNC grinding centres with the necessary technology for grinding complex shapes with very narrow tolerances. This technology, together with EDM and high-speed machining makes it possible producing any special shape.TiN coating, different coatings to be applied depending on the material. using state-of-the-art CAD software.

|

Our advantages |

1.High quality |

|

2.Reasonable price |

|

|

3.On time delivery |

|

|

4.Good After-sale service |

|

|

5.Strict quality control |

|

|

6.All the Punching Die are automotic. |

|

|

We will offer you |

1.In-time response on letters, telephone calls or fax |

|

2.In-time supply the quotation and Punching Die designs |

|

|

3.In-time communication on the technical points |

|

|

4.In-time sending pictures for the Punching Die machining progress and Punching Die finishing schedule |

|

|

5.In-timePunching Die test and sample delivery |

|

|

6.In-time Punching Die delivery. |

|

Q1:Are you a factory or trading company? |

|

A1:We are a factory, Henghui has 7,000 square meters of manufacturing plants and R&D bases. |

|

Q2:Where is your factory located? How can I visit there? |

|

A2:Our factory is located in Hailong Village, Baishiyi Town, Jiulongpo District, Chongqing City, China. All our clients, from home or abroad, are warmly welcome to visit us at anytime. |

|

Q3:What is the material of your products? |

|

A3:The material is DC53,SKD11,D2,SKH-9,SKH-51, or as our clients’ requirements. |

|

Q4: The maximum press your factory have available ? |

|

A4: Our factory has 30T,60T,160T punching machines |

|

Q5::How does your factory do regarding quality control? |

|

A5: Quality is priority. Henghui people always attach great importance to quality controlling from the very beginning to the very end. All the molds, the QC measure with threeDmeasuring equipments regularly. |

Packaging Details:Carton Box; Export Standard Package, Or As Client's Requirement.

Delivery Detail:According To The Quantity Of The Order, About 12-15 Days.

Related Keywords