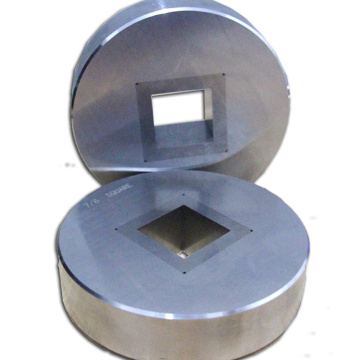

Screw Mold Die Cutting Knife cut wire

- Min. Order:

- 300 Piece/Pieces

- Min. Order:

- 300 Piece/Pieces

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Chong Qing, Shang Hai, Shen Zhen Or As Client's Requirement.

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 300 Piece/Pieces per Month |

|---|---|

| Payment Type: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Cash,Credit card |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,CIP |

| HS Code: | 8207209000 |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Chong Qing,Shang Hai,Shen Zhen Or As Client's Requirement. |

Screw Mold With Material of VA80 The Carbide Die Cutting Knife

Product introduction

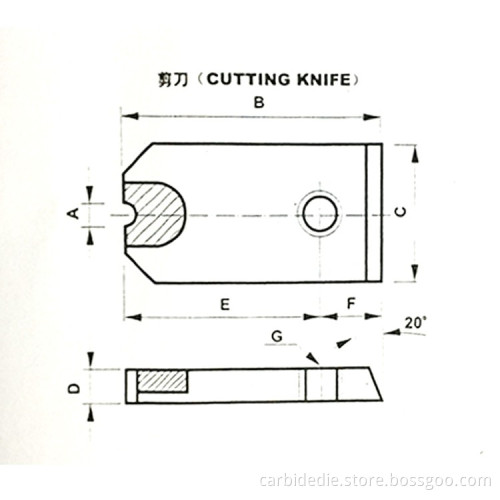

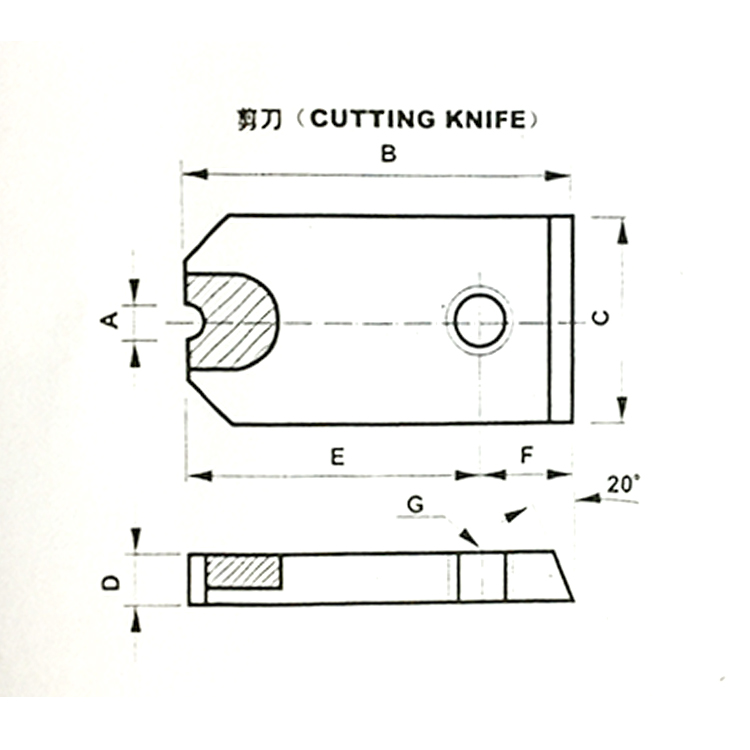

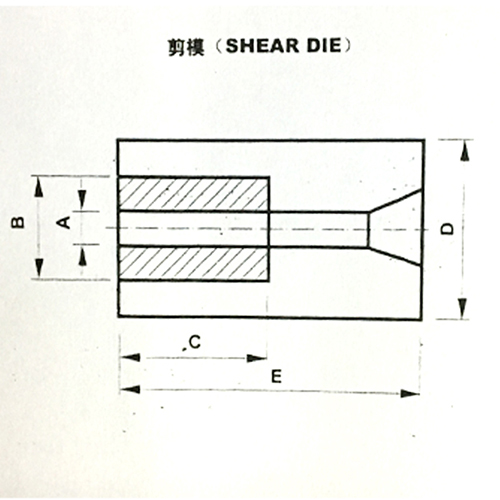

| Cutting knife for high quality raw materials |

| Cutting knife for the rich production experience |

| Cutting knife for advanced process equipment |

| Cutting knife for reliable quality assurance |

Until the mid-1900s, most precision wear parts were made of steel. Even today, steel parts are still in use due to their affordability, as tungsten carbide parts tend to cost more up front. The performance benefits that tungsten carbide dies have to offer, however, easily justify their price point.

The primary advantage of tungsten carbide is its strength. Endurance Carbide’s tungsten carbide dies, which are notable for offering more satisfactory performance than their steel counterparts, tend to last significantly longer, too – even in extreme conditions. Thanks to this durability, our tungsten carbide dies require replacement much less often than typical steel dies, which not only reduces overall maintenance costs, but lessens machine downtime as well.

Henghui will according to your product demand suggest Cutting knife's tungsten steel grades, or according to your requirements.

Features

| 100% quality guarantee |

| Various size for selection |

| Professional technical support |

| OEM & ODM are welcomed |

| Small order is acceptable |

| Factory service with competitive service in the market |

| Delivery in time |

| Flexible payment terms(T/T, western union, etc.) |

| Best after-sales service |

Main material:

Reasonable choice of carbide material will greatly improve the service life of die

|

|

Item |

Co |

Grain Size |

Density |

Hardness |

TRS |

Impact Strength |

application |

|

Medium-Grained |

|

Co% |

μm |

g/cm² |

HRA |

Kgf/mm² |

Kgf/m-cm² |

|

|

KG2 |

6.5% |

2~3 |

14.90 |

90.5 |

320 |

0.28 |

Drawing die |

|

|

KG3 |

9% |

2~3 |

14.61 |

89.3 |

340 |

0.52 |

Extrusion die |

|

|

KG5 |

12% |

2~3 |

14.31 |

88.3 |

340 |

0.58 |

Extrusion die |

|

|

KG6 |

14% |

2~3 |

14.12 |

87.3 |

320 |

0.65 |

Extrusion die |

|

|

Coarse -Grained |

ST6 |

15% |

3~6 |

13.80 |

86.0 |

270 |

0.78 |

Stainless steel |

|

ST7 |

20% |

2~6 |

13.40 |

85.3 |

270 |

0.80 |

Stainless steel |

|

|

EA65 |

18% |

2~6 |

13.73 |

85.0 |

300 |

0.80 |

Carbon steel screw/cutting die |

|

|

VA80 |

20% |

3~6 |

13.58 |

84.0 |

280 |

0.85 |

impact resistance |

|

|

VA90 |

22% |

6~9 |

13.39 |

82.5 |

240 |

0.90 |

impact resistance |

Related Keywords