Punching Mold Shaping Mode JMR M6

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Express, Ocean, Land

- Port:

- Chongqing, Shanghai, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000 Piece/Pieces per Month |

|---|---|

| Payment Type: | T/T,MoneyGram,credit card |

| Transportation: | Express,Ocean,Land |

| Port: | Chongqing,Shanghai,Shenzhen |

Header punch standard:

JIS, ANSI, DIN, ISO, BS, GB, and NON-STANDARD .

The common head style:

Flat head, pan head , oval head , binding head , round head, truss head, button head, pf head, cheese head, fillister head and so on .

The common driver:

Phillips , Phillips and slot combination, slotted, hexagon, six-lobe (torx), six-lobe tamper , six-lobe/slot , pozidriv , square, square/slot , Phillips/square, triangle and so on .

The coating about the screw header punch:

Without coating,

With TIN coating-yellow coated,

With TILAN coating-black coated

The standard size:

12x25mm

14x25mm

18x25mm

23x25mm

The unit weight about the header punch:

12x25mm: 25g/pc

14x25mm: 30g/pc

18x25mm: 50g/pc

23x25mm: 80g/pc

Our advantages:

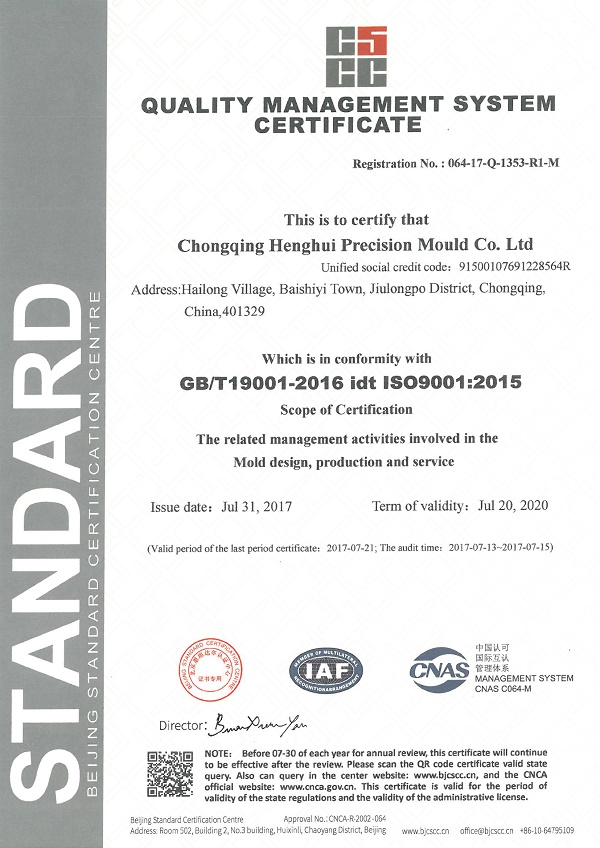

1.High quality

2.Reasonable price

3.On time delivery

4.Good After-sale service

5.Strict quality control

We can offer you:

1.In-time response on letters, telephone calls or fax

2.In-time supply the quotation and TRIMMING DIE designs

3.In-time communication on the technical points

4.In-time sending pictures for the die machining progress and die finishing schedule

5.In-time mold test and sample delivery

6.In-time delivery.

We will suggest the best mode of transportation or choose the mode of transportation according to your requirements.

Related Keywords