Phillips Second Punch with M2/M42 High Precision Material

- Min. Order:

- 30 Piece/Pieces

- Min. Order:

- 30 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Chongqing, Shanghai, Shenzhen or As Client's Need

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 2000 Piece/Pieces per Month |

|---|---|

| Payment Type: | T/T,Western Union,MoneyGram,credit card |

| Incoterm: | FOB,CIF,EXW,CIP |

| HS Code: | 8207309000 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Chongqing,Shanghai,Shenzhen or As Client's Need |

The Main Material and Advantages of the Second Punch:

The material selection of punch is mainly high-speed steel. The commonly used materials include Japanese SKH9, SKH55, SKH59 and American M2, M35 and M42.The main characteristic of the material is that the material can maintain good red hardness during high-speed upsetting, and the wear resistance is also very good, and can ensure a certain toughness

The choice of the header punch material is the key step, followed by the surface coating, to improve the high temperature resistance and wear resistance of the header punch, so as to achieve the best use effect and the longest life of the header punch.

Standard:

JIS, ANSI, DIN, ISO, BS, GB, and NON-STANDARD .

The Common Head Style:

Flat head, pan head , oval head , binding head , round head, truss head,

button head, pf head, cheese head, fillister head and so on .

The Common Driver:

Phillips , Phillips and slot combination, slotted, hexagon, six-lobe (torx),

six-lobe tamper , six-lobe/slot , pozidriv , square, square/slot , Phillips/square,

triangle and so on .

The Coating about the Screw Header Punch:

Without coating,

With TIN coating-yellow coated ,

With TILAN coating-black coated

The Standard Size:

12x25mm

14x25mm

18x25mm

23x25mm

The Unit Weight about the Header Punch:

12x25mm: 25g/pc

14x25mm: 30g/pc

18x25mm: 50g/pc

23x25mm: 80g/pc

The Life of Screw Header Punch

Without coated punch for iron/ carton steel screw : 20,000-30,000pcs.

Without coated punch for stainless steel screw : 4000-5000pcs.

With TIN coated punch for iron/ carton steel screw : 80,000-100,000pcs.

With TIN coated punch for stainless steel screw : 70,000-80,000pcs.

With TILAN coated punch for iron/ carton steel screw : 130,000-140,000pcs.

With TILAN coated punch for stainless steel screw : 100,000-110,000pcs.

♦ Order quality and on-time shipment safeguards

♦ 100% refund of the Trade Assurance Amount of orders not meeting spreed delivery or quality terms

♦ Supplier performance feedback system allows buyers to rate and review thier experience

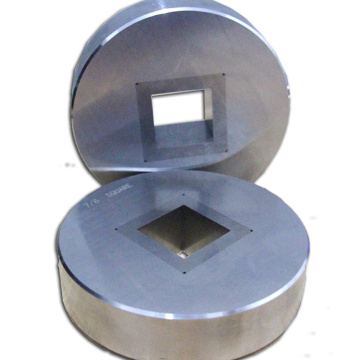

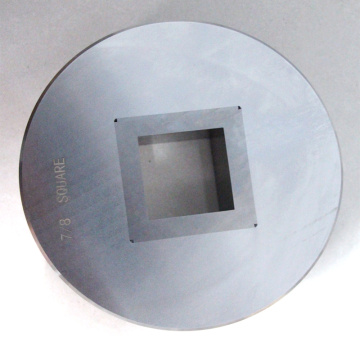

Cold Heading Die

Carbide Punches And Dies

Tungsten Carbide Die

Cold Forging Die

HSS Punches

Punch Pin

Second Punch

Second Punch Case

Carbide Punch Pin

Trimming Die

Thread Rolling Die

Related Keywords