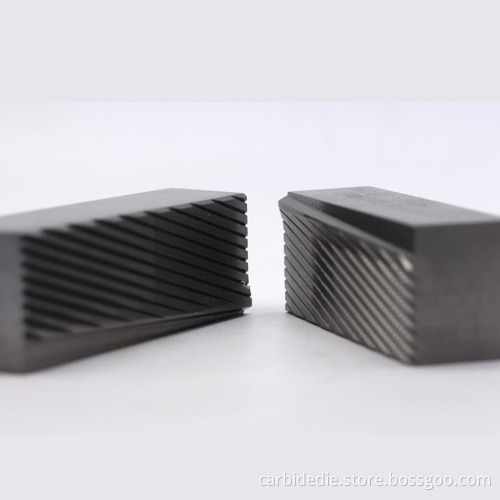

High quality of precision thread rolling die

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Chongqing OR ACCORDING TO THE CLIENT

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 200 Set/Sets per Month THREAD ROLLING DIE |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,CIP,DDP |

| HS Code: | 8207209000 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Chongqing OR ACCORDING TO THE CLIENT |

High quality of China precision thread rolling die

The thread rolling die is a commonly used thread processing tool for machining fasteners and bolt threads in the standard fastener industry. The processing principle is cold extrusion molding. Due to high production efficiency, low processing cost, high precision and strength of the machined thread, surface quality, so it has been widely used.

Factors affecting the service life of the thread rolling die:

1. Materials: We generally use high quality DC53 and SKH9 materials.

2. Heat treatment: heat treatment is undoubtedly the most important factor affecting the service life of the thread rolling die. Different materials and different purposes of the thread rolling die should use different heat treatment processes.

3. Machining dimensional accuracy has a significant impact on the life of the thread rolling die.

4. Conditions of use: Depending on the condition of the machine and the hardness of the blank, as well as the type of lubricant and coolant, it also depends on the actual deviation and size of the shape of the blank, in particular the chamfer of the head of the screw.

How to choose material for thread rolling die

(1) Good hardenability, high matrix hardness and good wear resistance.

(2) Dimensional stability.

(3) Impact strength and appropriate strength.

(4) Machinability and hot workability.

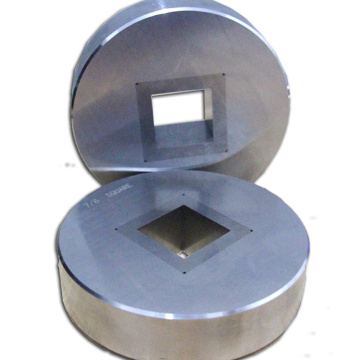

Other product:

Cold Heading Die

Carbide Punches And Dies

Tungsten Carbide Die

Cold Forging Die

HSS Punches

Punch Pin

Second Punch

Second Punch Case

Carbide Punch Pin

Trimming Die

Related Keywords