Flat Thread Rolling Die For Bolts And Screws

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Chongqing, Shanghai, Shenzhen or As Client's Need

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 200 Piece/Pieces per Month Hex Punches |

|---|---|

| Payment Type: | T/T,MoneyGram,credit card |

| Incoterm: | FOB,CFR,CIF,EXW,CIP,Express Delivery,DDP,DDU |

| HS Code: | 8207209000 |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Chongqing,Shanghai,Shenzhen or As Client's Need |

GB / T 972 "Thread rolling plate" standard stipulates that the thread rolling plate is made of 9SiCr, Cr12MoV steel, the hardness of the working part is 59 ~ 62HRC, if> 62HRC is easy to collapse, <59HRC is easy to wear; quenched martensite <3; There should be no decarburization and low hardness on the working surface; there should be no defects such as cracks, nicks, rust and grinding burns on the surface of the thread rolling board.

According to the working conditions of the thread rolling board, the selected materials should have the following properties:

(1) Good hardenability, high matrix hardness and good wear resistance;

(2) Good dimensional stability;

(3) Good impact toughness and appropriate strength;

(4) Good machinability and hot workability.

Henghui will choose the suitable carbide materials of products, combined with perfect technology, makes the carbide dies to achieve a better life.Tungsten carbide straight hole dies with the property of high wear resistance, good polishing performance, low friction coefficient, etc.and has very high compressive strength.

Even today, steel mold are still in use due to they're cheap, as tungsten carbide parts tend to cost more up front. The performance benefits that tungsten carbide dies have to offer, however, easily justify their price point.

The primary advantage of tungsten carbide die is strength. Carbide dies, which are notable for offering more satisfactory performance than steel counterparts, tend to last significantly longer, too – even in extreme conditions. Thanks to this durability, our tungsten carbide dies require replacement much less often than typical steel dies, which not only reduces overall maintenance costs, but lessens machine downtime as well.

Packaging Details:Carton Box; Export Standard Package, Or As Client's Requirement.

Delivery Detail:According To The Quantity Of The Order, About 12-15 Days.

♦ Order quality and on-time shipment safeguards

♦ 100% refund of the Trade Assurance Amount of orders not meeting spreed delivery or quality terms

♦ Supplier performance feedback system allows buyers to rate and review thier experience

Keyword

Other product:

custom hole punch

hole punch and die

tungsten carbide die

cold heading punches

punch and die tool

die punches for metal

progressive draw dies

tungsten carbide heading die

Cold Heading Die

Carbide Punches And Dies

Tungsten Carbide Die

Cold Forging Die

HSS Punches

Punch Pin

Second Punch

Second Punch Case

Carbide Punch Pin

Trimming Die

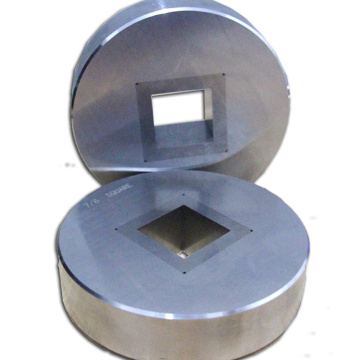

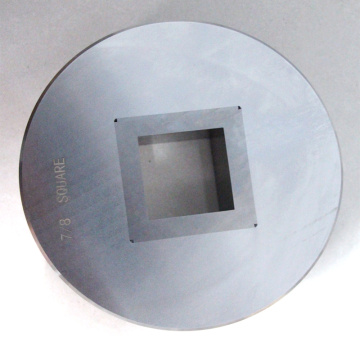

Thread Rolling Die

Nut Forming Dies

Die Cutting Knife

Shear Die

Drawing Die

Extrusion Die

Carbide Die

Drill Point Die

Hex Punch

First Punch Die

First Punch Case

Related Keywords