Thread Rolling Dies With Rational Design

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 2000 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,D/P,D/A,T/T,MoneyGram,cash |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Chongqing |

Various Cheap Wholesale Thread Rolling Dies With Rational Design For Manufacturer

Material: DC53, M2, H9

The section size or plates size: Length*Height*thickness(for example, 90/105x25x25mm)

Long life of the thread rolling die

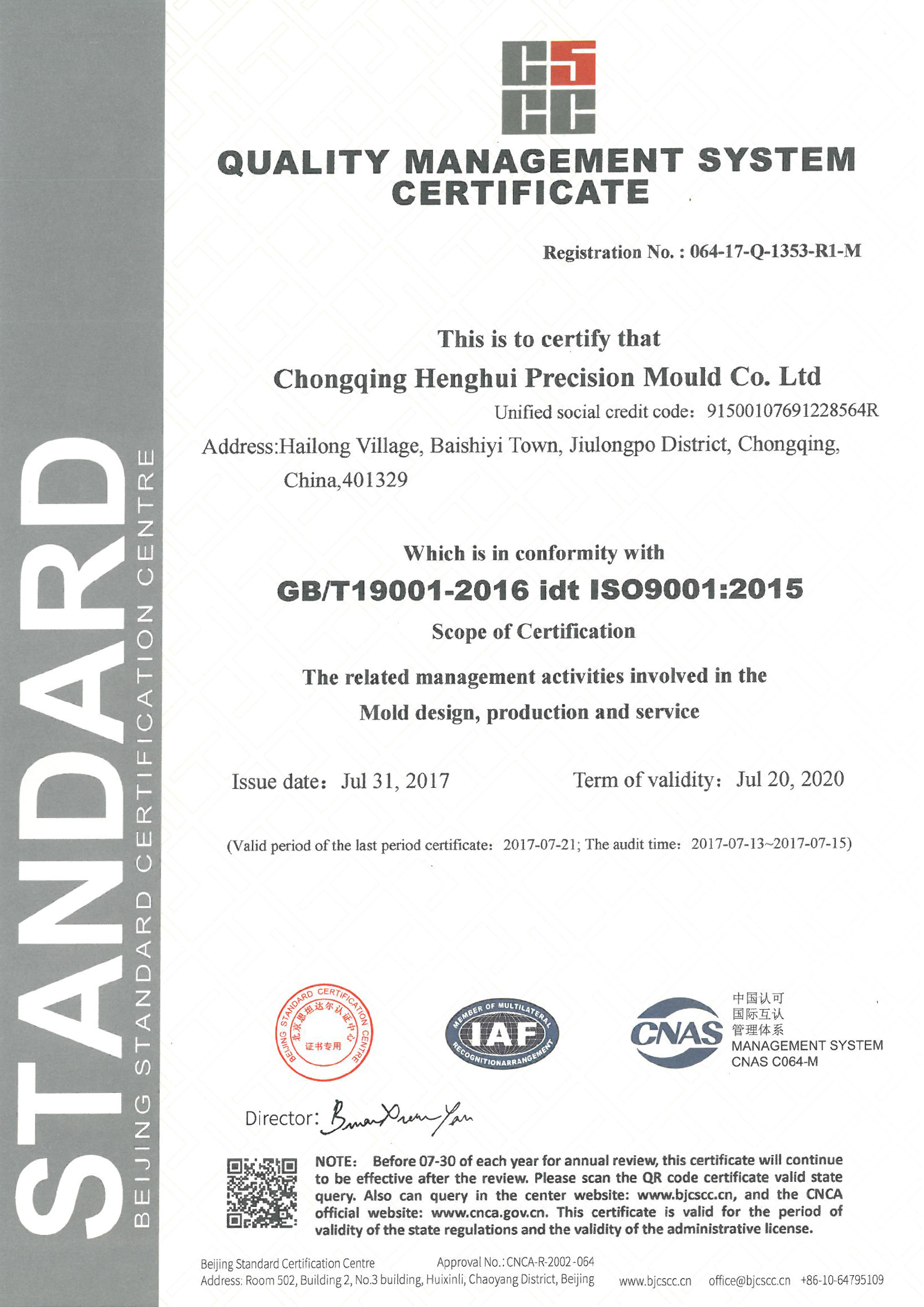

Henghui is specialized in the making of screw thread rolling dies, made of best raw materials available in the market. These screw thread rolling dies are designed professionally by our engineers per customers’ specifications or work pieces. Each staff tries try his best to have screw thread rolling dies with high accuracy, high strength and high stability by high skills and strict quality control system.Therefore the screw thread rolling dies life is longer than dies produced by other companies based on the same materials and the same price or even lower price.

Henghui manufacture thread rolling dies taking the needs of our customers very much into account. The range of thread rolling dies covers most of threading machines on the market. Likewise, we cover all kinds of screw threads.

We also manufacture custom thread rolling dies to customer specifications. You can see examples of different designs and shapes in the product details page.

Furthermore, we advise our customers in choosing the type of thread rolling die that best suits their needs. You can send your technical inquiries to us, and we will be in touch within 24 hours to offer you the best solution.

usage

The thread rolling die is a commonly used thread processing tool for machining fasteners and bolt threads in the standard fastener industry. The processing principle is cold extrusion molding. Due to high production efficiency, low processing cost, high precision and strength of the machined thread, surface quality, so it has been widely used.

Factors affecting the service life of the thread rolling die:

|

1.Materials: We generally use high quality DC53 and SKH9 materials.

|

|

2. Heat treatment: heat treatment is undoubtedly the most important factor affecting the service life of the thread rolling die. Different materials and different purposes of the thread rolling die should use different heat treatment processes. |

|

3.Machining dimensional accuracy has a significant impact on the life of the thread rolling die.

|

|

4. Conditions of use: Depending on the condition of the machine and the hardness of the blank, as well as the type of lubricant and coolant, it also depends on the actual deviation and size of the shape of the blank, in particular the chamfer of the head of the screw. |

Chongqing Henghui precision mold Co., Ltd. is a professional screw mold production enterprise with strong technical force, professional production and strict quality control. Main production standard, non-standard special screw mold. According to the customer's requirements, we can produce and order: straight body, shrinking die, closing die, strong binding die, and triangle, hexagon and other multilateral main dies; carbide upper and lower punching and punching sleeve; sleeve, combined die sleeve; cutter; thread rolling die; Six-Lobe thimble, Six-Lobe protection sleeve; straight body, step, tail hole and other multi specification punching needles; punch, thread plate (thread rolling die) and other multi specification screw forming Mold.

| Our advantages | 1.High quality |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the mold are automotic. | |

| We will offer you | 1.In-time response on letters, telephone calls or fax |

| 2.In-time supply the quotation and mold designs | |

| 3.In-time communication on the technical points | |

| 4.In-time sending pictures for the mold machining progress and mold finishing schedule | |

| 5.In-time mold test and sample delivery | |

| 6.In-time mold delivery. |

|

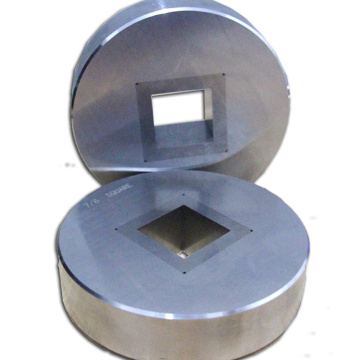

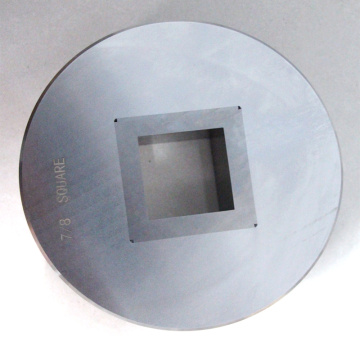

Carbide die:Straight hole dies/Extrusion dies /Nut die /Segmented Hex Dies /Cutter&knife |

||||

|

Tube drawing die |

Cutting&Trimming dies |

thread rolling die |

2nd punch |

punch pin HSS |

Usually, we choose the following ways to transport our molds, if you have other options or requirements, we are also welcomed.

Pre-sale

First confirm the types and quatity with customers

Patient, serious, carefully

Arrange to produce and care for the leadtime

Before delivery , confirm the items carefully

After sales

Arrange to delivery as soon as possible

Confirm the items if arrived at customers' hands

Get feedback from customers and try to do best

Related Keywords