Simple Cutting&Trimming Dies for Making Screw Head

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Express, Ocean, Air

- Port:

- Chongqing

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 3000 Piece/Pieces per Month |

|---|---|

| Payment Type: | T/T |

| Transportation: | Express,Ocean,Air |

| Port: | Chongqing |

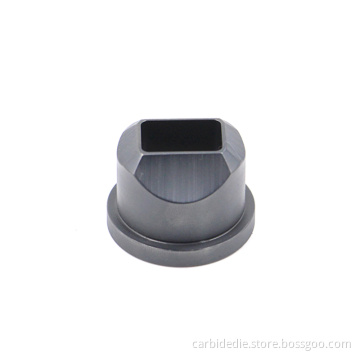

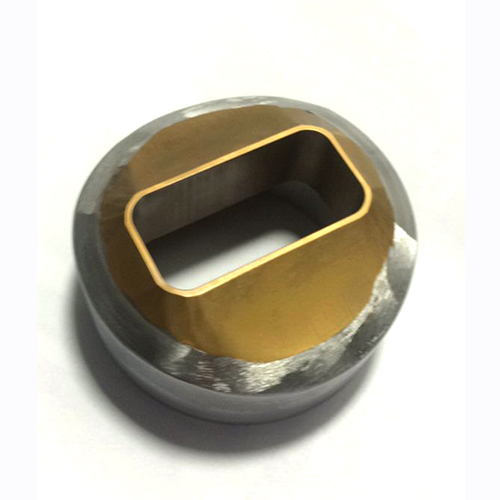

High Precision And Simple Cutting&Trimming Dies for Making Screw Head

Trimming Dies

Perfect tangent radius

Surface coating

± 0.005 mm tolerances.

Competitive prices.

One of the screw-formed tools, trimming die is used to form the head of screw. Square, hexagon and octangle are the common trimming die types.

Trimming die is used to making hex head or square head bolt to form the head shape. There are many kinds of material for choice like M2 or M35 etc. In order to extend the lifetime, surface Tin/TiALN-coated is considerable.

Trimming dies are promptly used in industry to trim the heads of bolts & screws of different shapes by removing distorted, undesirable angular part and sizes of high precision. It leads to create innovative product of perfect sizes and precision without having process of unnecessary resizing that wastes not only money but time also leaving behind more wastage. We are highly in making these kind of high tech dies of best performance with very low and competitive rate.

The manufacture of cutting and trimming dies with different profiles is carried on high precision grinding centres, high-speed machining centres, wire and electrode EDM and CNC lathes for hard lathing (steel and carbide) based on Henghui’s technology. The technical department will help selecting the most suitable steel or carbide tool for the material to be cut.

Chongqing Henghui Precision Mold Co., Ltd. has CNC lathes, CNC machining centers, CNC Cylindrical Grinding Machine, CNC EDM machine, CNC Cutting Machine, Milling Andam Drilling Machine ,etc.We also have various types testing equipment,such as Rockwell Hardness Tester,Projector,3D Image Measuring Instrument,etc. Henghui using high-quality tungsten carbide material and professional vacuum heat treatment.We design,manufacturing and supply high-quality precision molds for customers who engaged in cold heading and hot upsetting industries.About our molds , the relative standard deviation can be controlled within 0.005mm, concentricity can be controlled within 0.01mm. Strict accordance with ISO9001:2015 quality management system requirements of the operation,can ensure provide timely and high-quality service for our customers.Our products has exported to Southeast Asia,Europe and the United States ."Customer first, quality first, technology first, dedicated service" is our consistent operating principles.Warmly welcome to negotiate business with us.

| Our advantages | 1.High quality |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the mold are automotic. | |

| We will offer you | 1.In-time response on letters, telephone calls or fax |

| 2.In-time supply the quotation and mold designs | |

| 3.In-time communication on the technical points | |

| 4.In-time sending pictures for the mold machining progress and mold finishing schedule | |

| 5.In-time mold test and sample delivery | |

| 6.In-time mold delivery. |

Q1:Are you a factory or trading company?

A1:We are a factory, Henghui has 7,00 square meters of manufacturing plants and R&D bases

Q2:Where is your factory located? How can I visit there?

A2:Our factory is located in Hailong Village, Baishiyi Town, Jiulongpo District, Chongqing City, China. All our clients, from home or abroad, are warmly welcome to visit us at anytime!

Q3:What is the material of your products?

A3:The material is carbide and high speed steel,like VA80,G6,ST7,DC53,SKD11,D2,SKH-9,SKH-51, or as our clients’ requirements.

Q4: The maximum press your factory have available ?

A4: Our factory has 30T,60T,160T punching machines

Q5::How does your factory do regarding quality control?

A5: Quality is priority. we having gained ISO 9001 Quality Authentication Certificate.

In order to provide our clients the best service,We have set up customer management platform.

Standing in our clients’s way. we know our clients’ demands and the problems we need to solve .

|

Drawings or samples provided |

We get the drawings or samples from our clients. |

|

R&D |

We support customer R&D. Make the files or improve the design if you needed. |

|

Quotation |

According to the drawings or samples |

|

Mold design |

Send mold design for confirmation within 3 days after getting mold charge |

|

Mold making |

Start to make the mold after design confirmed |

|

Test-run |

After mold is finished, we’ll test it and get samples |

|

Sample confirmation |

Send the free samples to client to make sure perfect |

|

(Mold modification) |

(If the sample is not ok, we’ll modify the mold for free, Then send free samples to you again...until meet your demands) |

|

(Mold delivery) |

(Shipping mold out if no need to injection plastic parts, packed by wooden case by see or by air, according to client’s requirements) |

|

Plastic Injection Service |

Start to high-volume production with the ordered mold. |

Usually, we choose the following ways to transport our molds, if you have other options or requirements, we are also welcomed.

Related Keywords