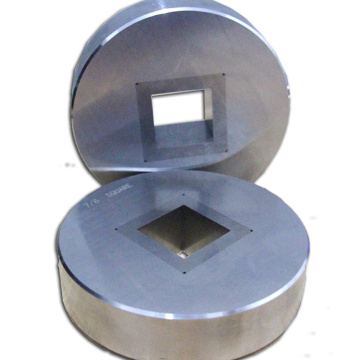

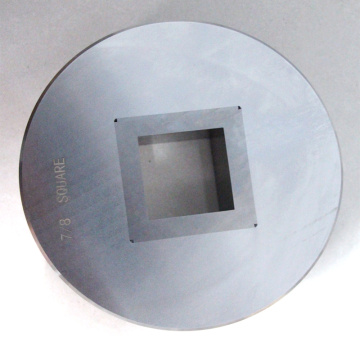

Customized Fastener Mold Carbide Material Screw Mold

-

$99.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Chongqing, Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 2000 Piece/Pieces per Month |

|---|---|

| Payment Type: | T/T,Cash |

| Incoterm: | FOB,CIF,EXW,CIP |

| HS Code: | 8207209000 |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Chongqing,Shanghai |

Product Description

Product Description

Product Description

Screw molds are made of alloy materials with high strength and hardness, corrosion resistance, wear resistance and high temperature resistance, which is far longer than the service life of ordinary steel dies. It is a popular die in modern machinery industry. Its characteristics are as follows:

1) the guiding mechanism of the die adopts the four guide pillar ball mold base, and the stability, reliability and accuracy of the guiding mechanism are very high.

2) use T7 as the raw material of the hardened base plate to avoid the crushing of the cemented carbide die during stamping.

3) most of the formwork bases are made of 45 steel, hrc38-420, which is thicker than the general steel formwork and increases the rigidity.

4) at the die handle, in order to prevent the impact of the precision of the press on the stamping process of the carbide die, the floating die handle structure should be adopted as far as possible.

5) the clearance of the concave convex die is larger than that of the steel die.

6) in order to prevent the impact on the die during stamping, the fixed discharge plate structure is adopted, and the height h of the step is one thick material different from the thickness h of the guide plate.

The selection of the material for the cold heading die is very important. The service life time depends on the quality of the tungsten carbide inside. We use authentic CB-CERATIZIT tungsten carbide to ensure effective life.

Advantages

1.High quality

2.Reasonable price

3.On time delivery

4.Good After-sale service

5.Strict quality control

2.Reasonable price

3.On time delivery

4.Good After-sale service

5.Strict quality control

We will offer you

1.In-time response on letters, telephone calls or fax

2.In-time supply the quotation and mold designs

3.In-time communication on the technical points

4.In-time sending pictures for the mold machining progress and mold finishing

schedule

5.In-time mold test and sample delivery

6.In-time mold delivery From Alibaba China Supplier.

2.In-time supply the quotation and mold designs

3.In-time communication on the technical points

4.In-time sending pictures for the mold machining progress and mold finishing

schedule

5.In-time mold test and sample delivery

6.In-time mold delivery From Alibaba China Supplier.

We supply for customer including:

Cold Heading Die

Carbide Punches And Dies

Tungsten Carbide Die

Cold Forging Die

HSS Punches

Punch Pin

Second Punch

Second Punch Case

Carbide Punch Pin

Trimming Die

Thread Rolling Die

Nut Forming Dies

Die Cutting Knife

Shear Die

Drawing Die

Extrusion Die

Carbide Die

Drill Point Die

Hex Punch

First Punch Die

First Punch Case

Cold Heading Die

Carbide Punches And Dies

Tungsten Carbide Die

Cold Forging Die

HSS Punches

Punch Pin

Second Punch

Second Punch Case

Carbide Punch Pin

Trimming Die

Thread Rolling Die

Nut Forming Dies

Die Cutting Knife

Shear Die

Drawing Die

Extrusion Die

Carbide Die

Drill Point Die

Hex Punch

First Punch Die

First Punch Case

Related Keywords

Related Keywords